Method for preparing desulfurizer for thermal power plant by using waste marble powder

A technology for abandoned marble and thermal power plants, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve problems such as stone powder discharge pollution, reduce production costs, protect limestone mine resources, and achieve huge ecological and economic benefits. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Raw material collection method:

[0024] (1) Each stone factory is required to classify the stone powder slurry produced by different stone materials for sedimentation, pressure filtration, and classified storage.

[0025] (2) Collect the marble slurry blocks that have been classified and stored by the enterprise, collect them in the shed, homogenize them with a forklift, and dry them in the sun. Through sampling and analysis, ensure that the chemical composition of calcium and magnesium carbonate reaches more than 90%.

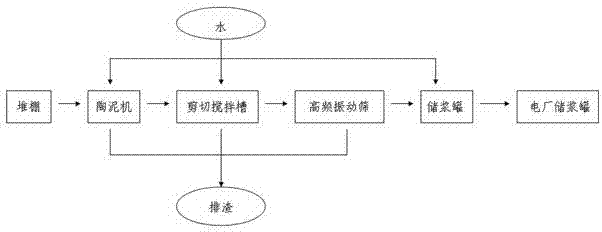

[0026] pulping process

[0027] (1) Push the marble powder with a moisture content of 15~30% directly into the mud pool by a forklift for low-speed coarse dispersion, and at the same time add a dispersant according to the proportion of the slurry, remove suspended impurities by suspension method, and remove them by settling chamber Coarse crumbs. The average residence time of the pulp block is not less than 30 minutes.

[0028] (2) The coarsely dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com