Process and device for removing hypophosphites and phosphites by advanced oxidation coupling technique

A technology of phosphite and combined use technology, which is applied in the fields of oxidized water/sewage treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc. problem, to achieve the effect of improving oxidation capacity, fast reaction speed and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

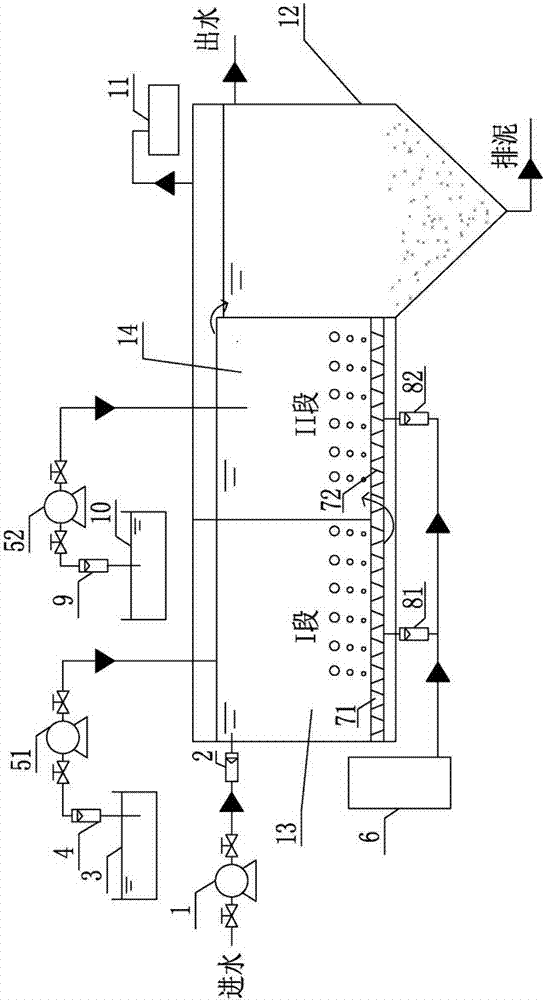

[0026] Figure 1 to Figure 2 The reference numerals in the figure are: water inlet pump 1; first liquid flow meter 2; hydrogen peroxide storage tank 3; second liquid flow meter 4; first centrifugal pump 51; second centrifugal pump 52; ozone generator 6; An aeration head 71; a second aeration head 72; a first gas flow meter 81; a second gas flow meter 82; a third liquid flow meter 9; a ferrous sulfate storage tank 10; an ozone tail gas destroyer 11; sludge sedimentation Pool 12; Section I reaction pool 13; Section II reaction pool 14.

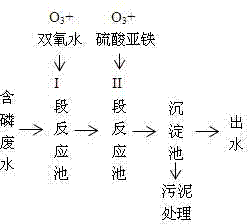

[0027] like figure 1 Shown, a kind of advanced oxidation combined technology removes the technology of times, phosphite, comprises the following steps:

[0028] S1. Inject ozone and hydrogen peroxide into the wastewater, and oxidize hypophosphite and phosphite to orthophosphate through the combined use of ozon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com