Preparation and application of N-methyl piperazinyl silane coupling agent

A technology based on silane coupling agent and methylpiperazine, which is applied in the field of organosilicon fine chemicals, can solve the problems of high requirements, easy yellowing, and affecting the effect of taking, and achieve good anti-pilling performance and good hydrophilicity , good resilience effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

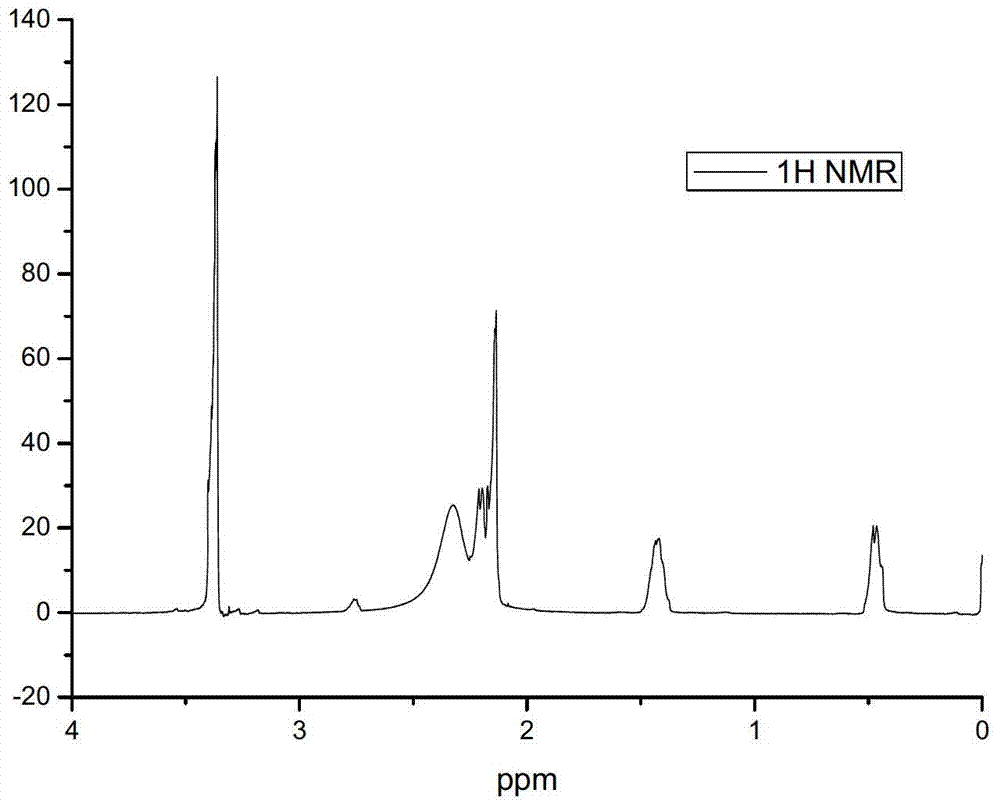

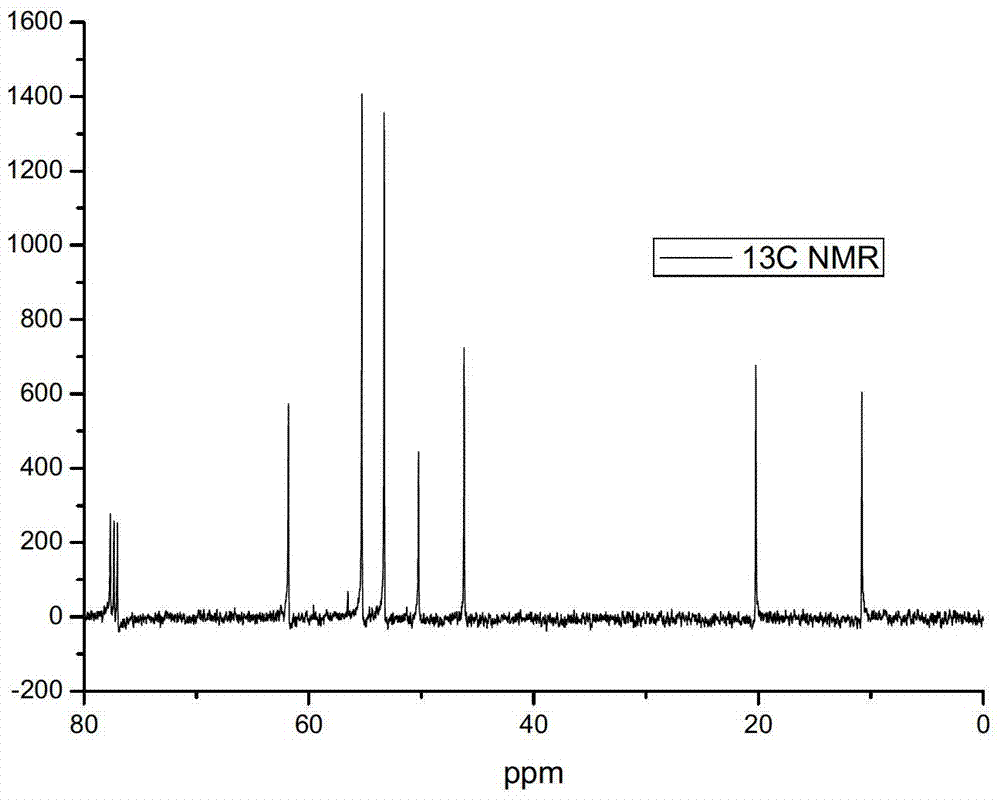

[0033] Embodiment 1, the preparation of N-methylpiperazinyl silane coupling agent

[0034] The specific route for the preparation of the N-methylpiperazinyl polysiloxane involved in this embodiment is as follows:

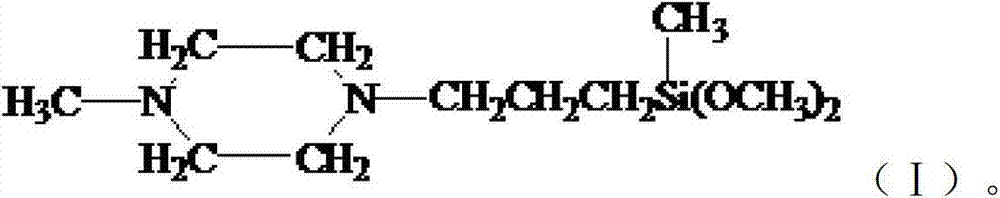

[0035] (1) Use N-methylpiperazine and chloropropylmethyldimethoxysilane as main raw materials to prepare N-methylpiperazinylpropylmethyldimethoxysilane, namely N-methylpiperazine base silane coupling agent; by-product is N-methylpiperazine hydrochloride, and the reaction equation is as follows:

[0036]

[0037] Wherein, the dosages of N-methylpiperazine and chloropropylmethyldimethoxysilane are shown in Table 1.

[0038] The N-methylpiperazinylsilane coupling agent prepared in this example is used to prepare fabric softening and finishing agents, polymer modifiers, release agents, coating additives, brighteners or cosmetic additives.

Embodiment 2~10

[0039] Embodiment 2~10, the preparation of N-methylpiperazinyl silane coupling agent

[0040] Embodiment 2~10 are the same as embodiment 1, wherein,

[0041] In the preparation of N-methylpiperazinylpropylmethyldimethoxysilane, the weight ratios of N-methylpiperazine and chloropropylmethyldimethoxysilane are shown in Table 1 respectively.

[0042] The prepared N-methylpiperazinyl silane coupling agent is used to prepare fabric softening and finishing agents, polymer modifiers, release agents, paint additives, brighteners or cosmetic additives.

[0043] Table 1

[0044]

[0045] In conjunction with temperature, reaction time, reaction pressure test, the reaction yield corresponding to each embodiment is shown in table 1, as can be seen, comprehensively considering yield and production efficiency, N-methylpiperazinyl propyl methyl dimethyl of the present invention The optimal process selection for the preparation of oxysilane is: the weight ratio of N-methylpiperazine to ...

Embodiment 11

[0046] Embodiment 11, the application of N-methylpiperazinyl silane coupling agent

[0047] The N-methylpiperazinylsilane coupling agent prepared in Example 8 is used to prepare the fabric softening agent as an example, and the specific steps are:

[0048] A, bulk polymerization of N-methylpiperazinylpropylmethyldimethoxysilane and octamethylcyclotetrasilane (also can be DMC, choose octamethylcyclotetrasilane in this embodiment) Obtain N-methyl piperazinyl amino polysiloxane, its equation is as follows:

[0049]

[0050] Since N-methylpiperazinylpropylmethyldimethoxysilane is used to prepare N-methylpiperazinylpolysiloxane, when the latter is applied to textile finishing, the molecular weight is less than 5000, and the softness of the treated fabric Not enough, more than 80000, difficult to emulsify. Therefore, the molecular weight of N-methylpiperazinyl polysiloxane is selected between 5000 and 80000, so m is limited to between 60 and 1000; at the same time, the prepar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com