Boron isotope abundance measuring method using carbon nanotube as ion emitting agent

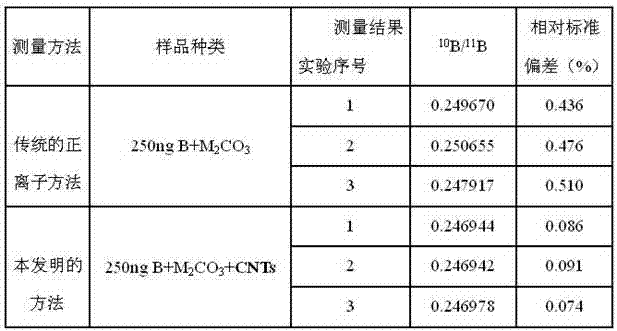

A technology of isotopic abundance and carbon nanotubes, which is used in measurement devices, preparation of test samples, material analysis by electromagnetic means, etc., can solve the problem of low positive ion ionization efficiency, difficulty in high-precision measurement, and isobaric It can improve the ion emission performance, the sample measurement results are accurate, and the emission intensity can be improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

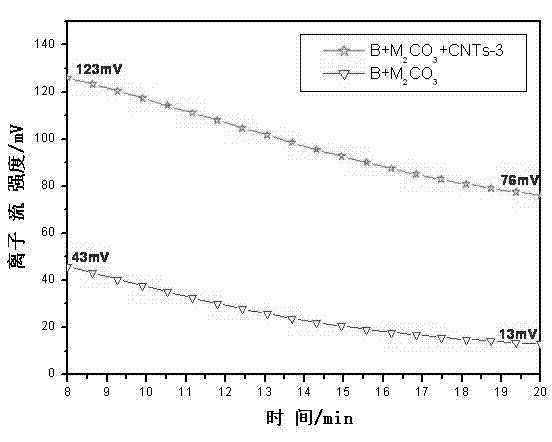

[0036] The measurement method disclosed in the present invention is mainly composed of three major steps of sample preparation, sample coating and sample measurement, and the three steps are now described in detail.

[0037] (1) Sample preparation: including carbon nanotube suspension preparation, generator solution preparation, and rhenium tape pretreatment, of which:

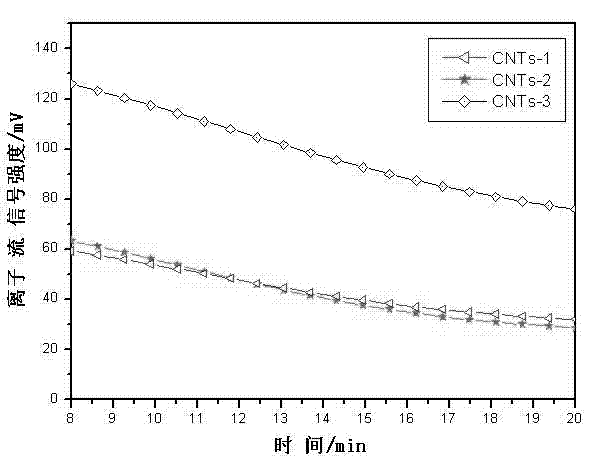

[0038] Preparation of carbon nanotube suspension: Weigh 0.02g of carbon nanotubes (CNTs) into a 25ml sample bottle, add 10ml of deionized water, and disperse ultrasonically for 15 minutes to form a uniform suspension for use. The tube suspension has not been used for a long time and needs to be ultrasonically dispersed before use.

[0039] The carbon nanotubes used are compound-walled carbon nanotubes with a diameter of 1 nm and a length of 5-15 μm.

[0040] After studying and comparing various solvents, such as ethanol, sucrose solution, acetone, etc., and considering the shedding of carbon nanotubes, the im...

Embodiment 2

[0051] The difference between this embodiment and embodiment 1 is only:

[0052] In step (1) of this embodiment, the carbon nanotubes used are composite-walled carbon nanotubes with a diameter of 9 nm and a length of 5-15 μm; the M / B molar ratio in the preparation of the generator solution is 1.0; During pretreatment: When degassing the double-tape inserts in the burning device, raise the temperature to 2100°C, and the burning time is half an hour. After the burning is completed, cool it to room temperature in a vacuum system, take it out and place it in a desiccator stand-by;

[0053] In step (2) of this embodiment: when one of the rhenium strips of the pretreated double-band insert is made into a sample strip, the process is as follows: one of the rhenium strips is placed on the sample applicator, and the boron sample (boron solution ) 1μL (250ng) was dropped on the center of the strip, and most of the water was dried at 180°C (dried until no visible droplets), then the cur...

Embodiment 3

[0059] The difference between this embodiment and embodiment 1 is only:

[0060] In step (1) of this embodiment, the carbon nanotubes used are composite-walled carbon nanotubes with a diameter of 4 nm and a length of 5-15 μm; the M / B molar ratio in the preparation of the generator solution is 0.75; During pretreatment, the double-tape insert is degassed in the burning device, and the temperature is raised to 2075°C. The burning time is half an hour. After the burning is completed, it is cooled to room temperature in a vacuum system, taken out and placed in a desiccator to wait. use;

[0061] In step (2) of this embodiment: when one of the rhenium strips of the pretreated double-band insert is made into a sample strip, the process is as follows: one of the rhenium strips is placed on the sample applicator, and the boron sample (boron solution ) 1μL (250ng), drop accurately on the center of the belt, dry most of the water at 170°C (dry to no visible droplets), disconnect the cu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com