Anticaking agent for soybean meal fermentation

An anti-caking agent and soybean meal technology, applied in the field of plant protein fermentation, can solve the problems of uneven distribution of fermented product quality, prolonging the drying process of fermented products, material stickiness, caking, etc., to achieve disease resistance and production The effect of short cycle and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

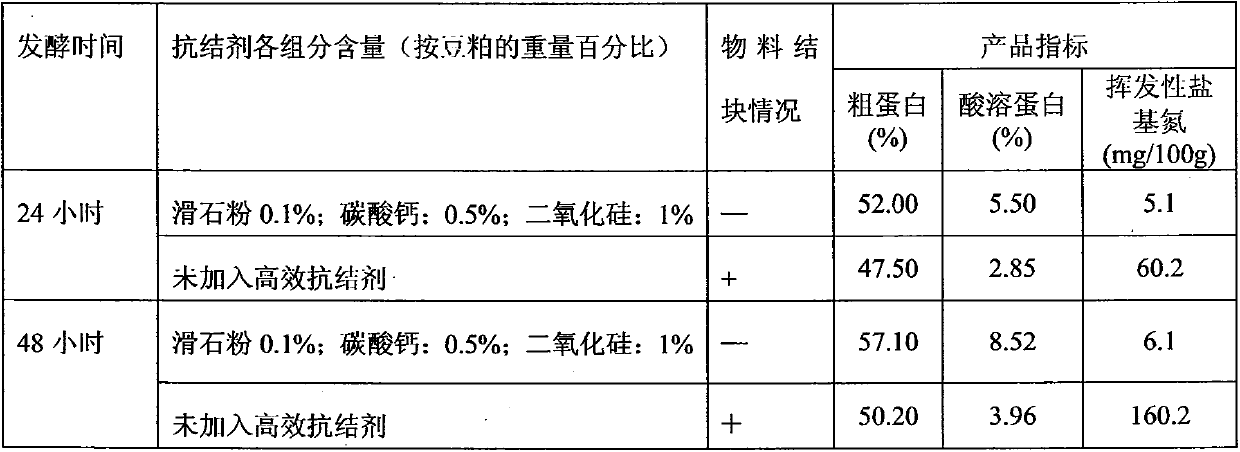

[0017] Embodiment 1: an anti-caking agent for soybean meal fermentation, added to the soybean meal, the anti-caking agent comprises the following components by weight percentage of the soybean meal:

[0018] Talc: 0.1%; Calcium Carbonate: 0.5%; Silicon Dioxide: 1%.

[0019] Add the anti-caking agent of the present embodiment 1 and the soybean meal without anti-caking agent after solid-state fermentation for 24 hours and 48 hours, the material caking situation and product quality index detection results are shown in Table 1.

[0020] Table I:

[0021]

Embodiment 2

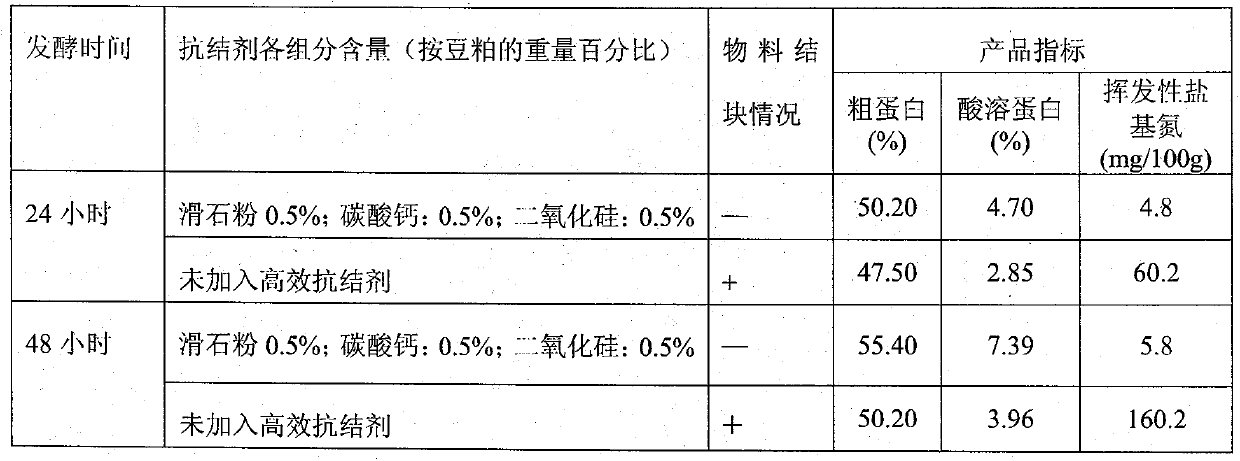

[0022] Embodiment 2: an anticaking agent for soybean meal fermentation, added to the soybean meal, the anticaking agent comprises the following components by weight percentage of the soybean meal:

[0023] Talc: 0.5%; Calcium Carbonate: 0.5%; Silicon Dioxide: 0.5%.

[0024] Table 2 shows the caking situation and product quality index test results of the soybean meal with the anticaking agent added in the second embodiment and the soybean meal without the anticaking agent after 24 hours and 48 hours of solid-state fermentation.

[0025] Table II:

[0026]

Embodiment 3

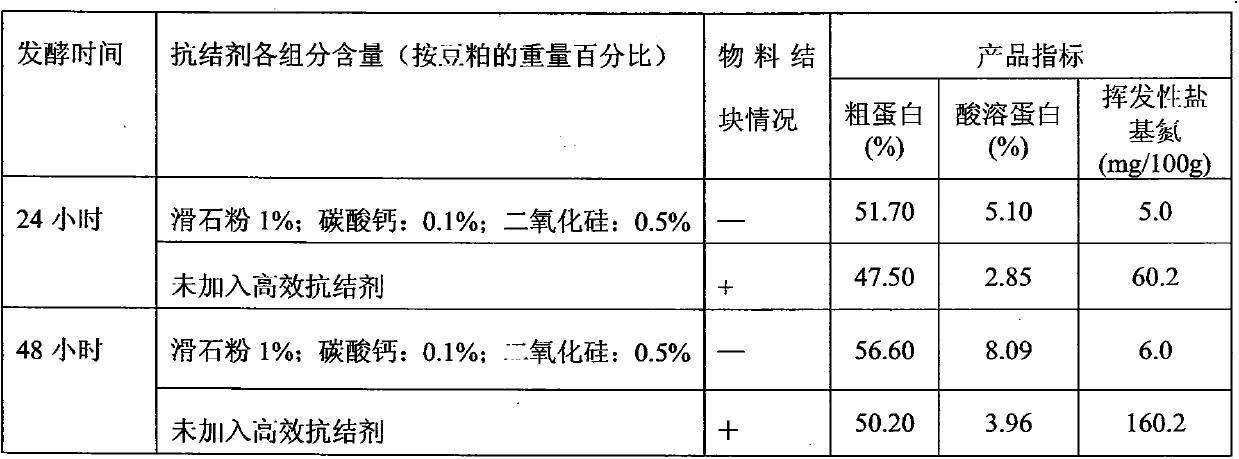

[0027] Embodiment three: an anti-caking agent for soybean meal fermentation, added to the soybean meal, the anti-caking agent comprises the following components by weight percentage of the soybean meal:

[0028] Talc: 1%; Calcium Carbonate: 0.1%; Silicon Dioxide: 0.5%.

[0029] Table 3 shows the caking situation and product quality index test results of the soybean meal with the anti-caking agent added in the third embodiment and the soybean meal without the anti-caking agent after 24 hours and 48 hours of solid-state fermentation.

[0030] Table three:

[0031]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com