Core-shell nano-copper nickel solid solution/polyaniline composite materials and preparation method thereof

A composite material and solid solution technology, applied in the field of composite materials and their preparation, can solve the problems of unstable chemical properties of composite materials, easy oxidation of nano metal particles, long preparation time, etc., and achieve improved electrical conductivity, low cost, and reaction time. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0024] Specific embodiment one: a kind of core-shell type nano copper nickel solid solution / polyaniline composite material, it is characterized in that it comprises the aqueous solution of aniline hydrochloride, solid solution microemulsion, oxidant and acetone; Wherein, the aqueous solution of aniline hydrochloride, The volume ratio of solid solution microemulsion, oxidant and acetone is 1: (3.75-20): (1.25-10): (0.75-20);

[0025] Among them, the aqueous solution of aniline hydrochloride is prepared by mixing aniline and HCl solution, the volume ratio of aniline and HCl solution is 1: (1.2-15), and the concentration of HCl solution is 1.0mol / L;

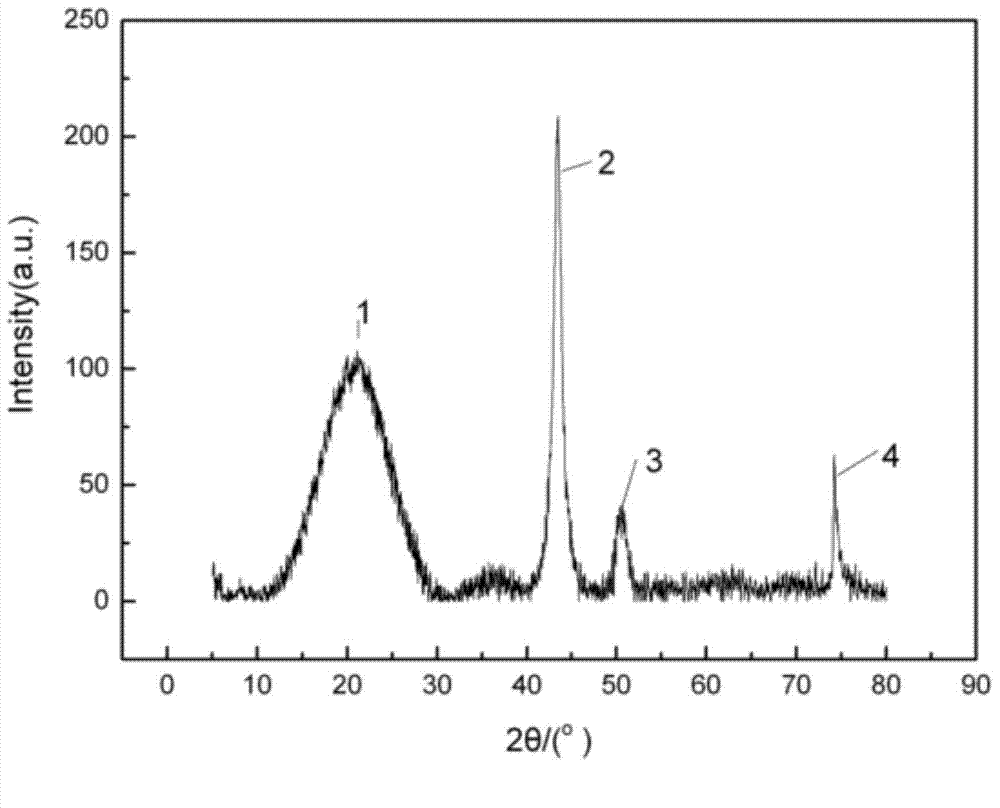

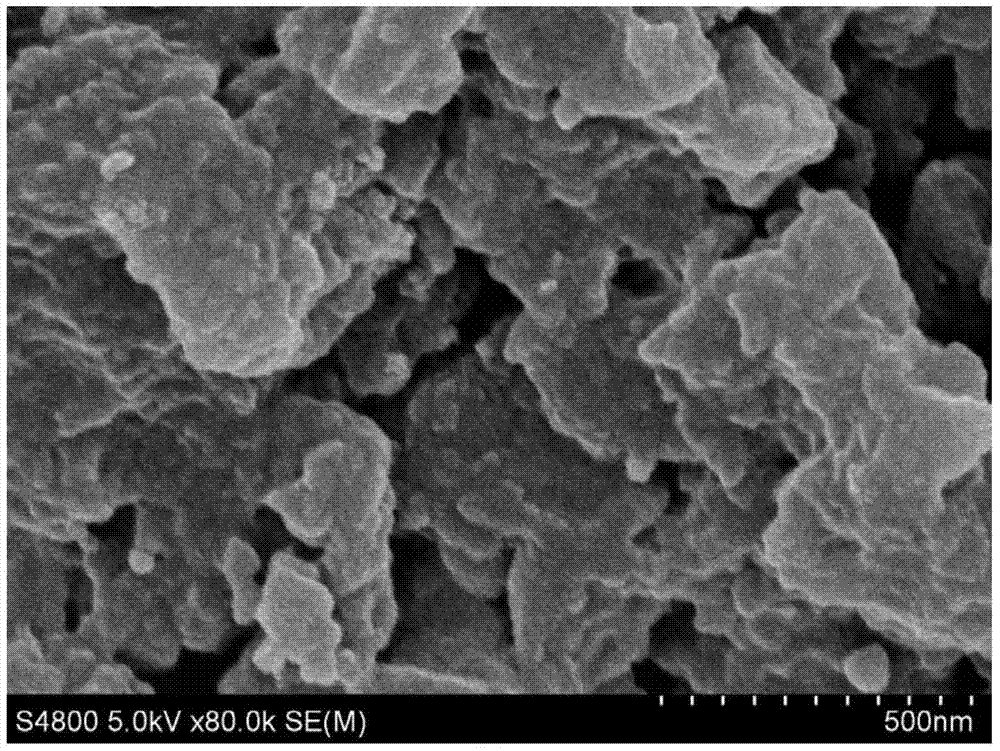

[0026] Among them, the solid solution microemulsion is made by mixing copper-nickel solid solution powder, toluene and SDBS solution; the mass volume ratio of copper-nickel solid solution powder, toluene and SDBS solution is 1g: (1mL-40mL): (100mL-2000mL), SDBS The mass percentage of the solution is 1%-5%; among them, the copper-nic...

specific Embodiment approach 2

[0028] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the volume ratio of the aqueous solution of aniline hydrochloride, solid solution microemulsion, oxidizing agent and acetone is 1:4.1:2.5:2.5. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0029] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the volume ratio of the aniline to the HCl solution is 1:2.5. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com