A kind of preparation method of electrochromic double-layer fabric

An electrochromic, double-layer fabric technology, applied in the direction of chemical instruments and methods, layered products, physical treatment, etc., can solve problems such as not easy to stir evenly, affect the quality of polyaniline, and uneven distribution of polyvinyl alcohol, etc., to achieve High sensitivity of reversible change and color change, increased electrochromic performance, low price effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

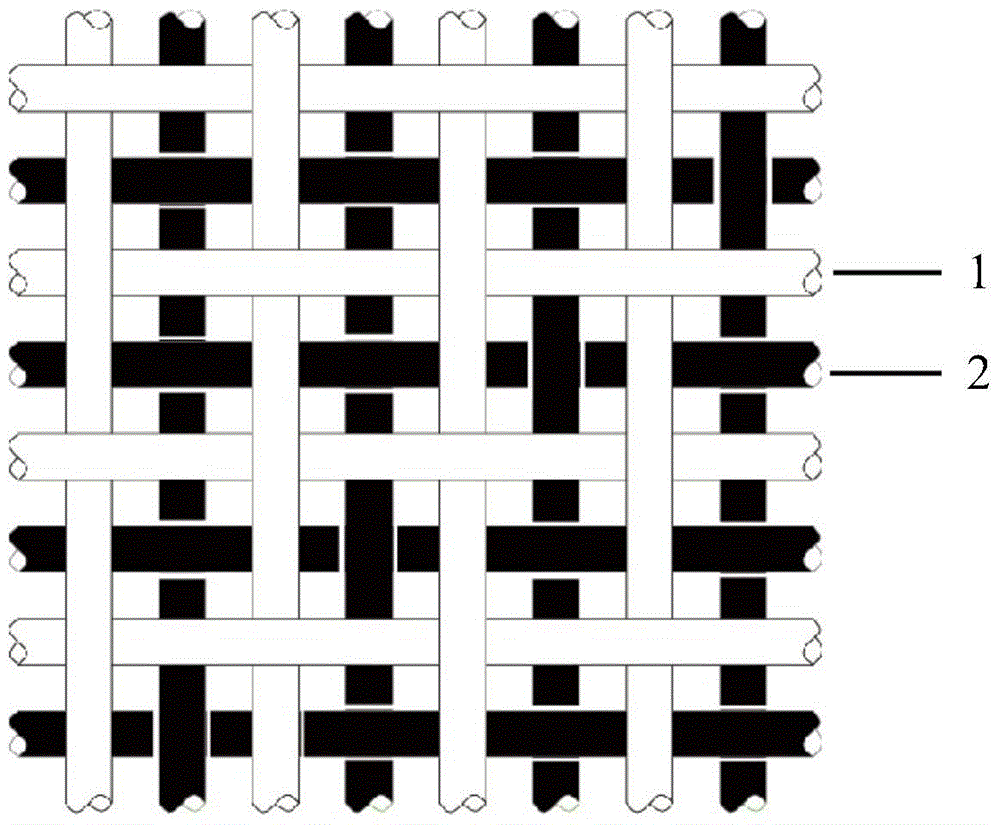

Image

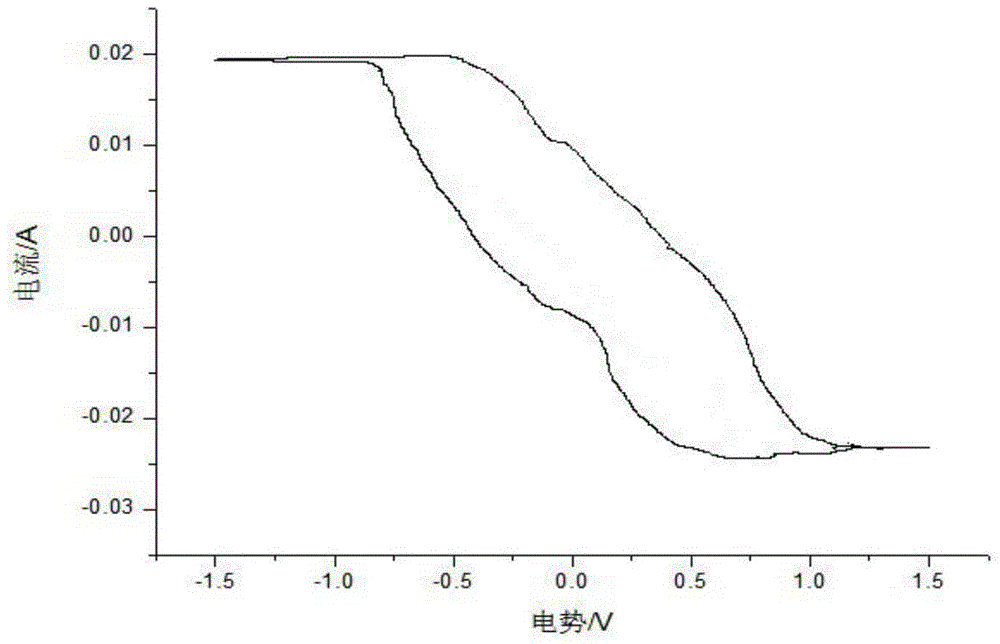

Examples

Embodiment 1

[0033] 1. Preparation of electrochromic fibers

[0034] (1), the preparation of polyaniline / polyvinyl alcohol emulsion:

[0035] Dissolve 1.5 grams of polyvinyl alcohol in 30 mL of deionized water at a temperature of 60°C, heat and stir at a low speed until the polyvinyl alcohol is completely dissolved into a colorless and transparent solution, and cool it for later use; in the cooled polyvinyl alcohol aqueous solution Add 0.77 gram of dodecylbenzenesulfonic acid and 0.2 gram of aniline monomer successively, stir with the rotating speed of 2500rpm, till producing milky white liquid; Slowly titrate the aqueous solution 10ml that contains 0.52 gram of ammonium persulfate in milky white liquid, within 30 minutes After the dropwise addition, the emulsion was stirred at a speed of 2500 rpm during the dropwise addition, so that the ammonium persulfate aqueous solution was uniformly dispersed in the reaction solution. The emulsion continued to be stirred for 10 hours, and the polyan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com