Composite pigment powder as well as preparation method and application thereof

A technology of composite pigment and powder, applied in the field of pigment powder and composite pigment powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

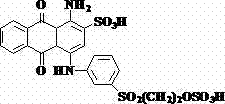

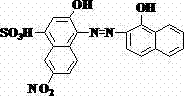

Image

Examples

preparation example 1

[0050] Preparation Example 1: Synthesis of Light Stabilizer

[0051] Take 10.12 g EV80 (α-[3-[3-(2H-benzotriazol-2-yl)-5-(1,1-dimethylethyl)-4-hydroxyphenyl]-1-one propyl]-ω-hydroxy poly(keto-1,2-ethanediyl)) into a 50 ml separable reaction flask, stirred and heated to 50°C, added 1,3,5-tris(6-iso Cyanatohexyl)-1,3,5-triazine-2,4,6-trione 4.04 g, N,N-dimethylacetamide 3.55 g, heated to 90°C, reacted for 2-3 hr (titration After the number of moles of NCO functional groups reached the end point of the reaction), the temperature was lowered to 70°C and 1.22 g of N,N-dimethylacetamide and 0.53 g of 2,2-bis(hydroxymethyl)butanoic acid were added, and the temperature was raised to 90°C to react 2- After 3 hr (titration of the molar number of NCO functional groups reaches the end of the reaction), cool down to 50°C to obtain the light stabilizer shown in the following formula (according to the general molecular weight measurement method, record its weight average molecular weight ...

preparation example 2

[0054] Preparation Example 2: Synthesis of Tb-DTPA Complex

[0055] Diethyltriaminepentaacetic acid (DTPA) was dissolved in anhydrous methanol to form 1 × 10 -3 mol / L solution, add triethylamine in an equimolar amount to the carboxyl group in the organic ligand, and then add an equimolar amount of terbium nitrate under stirring. After stirring for 2 h, remove the solvent on a rotary evaporator to precipitate out, filter , after washing with methanol, the solid was dried to obtain a Tb-DTPA complex with diethyltriaminepentaacetic acid (DTPA) as a ligand, which was reserved for future use.

preparation example 3

[0056] Preparation Example 3: Synthesis of Eu-DTPA Complex

[0057] Preparation Example 3 was implemented in the same manner as Preparation Example 2, except that Europium Nitrate was used instead of Terbium Nitrate, thereby preparing Eu-DTPA complex.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com