Ultraviolet curing stain-resistant and wear-resistant negative ion wood lacquer and preparation method thereof

A wood lacquer and light-curing technology, which is applied to biocide-containing paints, anti-fouling/underwater coatings, coatings, etc. It can solve the problems of weak scratch resistance, poor stain resistance of paint films, and low construction efficiency. problems, to achieve the effect of improving surface friction resistance, reducing surface friction coefficient, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

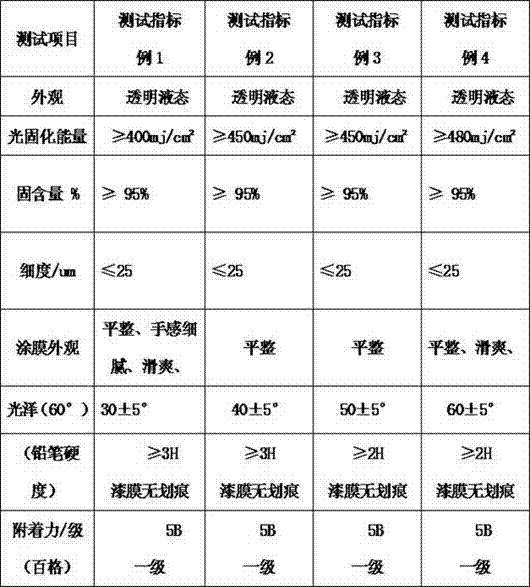

Examples

Embodiment Construction

[0026] Raw material name Portion Ratio Example 1 Portion Ratio Example 2 Serving Ratio Example 3 Serving ratio Example 4 bisphenol A epoxy acrylic 145g 145g 195g 245g Aliphatic polyurethane acrylic 250g 250 200g 150g 1-Hydroxyalkylhexylbenzophenone 50g 50g 50g 50g Tripropylene glycol diacrylate 200g 244g 306g 354g pentaerythritol triacrylate 100g 100g 100g 100g Antifouling additive 5g 1g 2g 3g Dispersant 3g 3g 3g 3g Defoamer 2g 2g 2g 2g leveling agent 2g 2g 2g 2g active amine 5g 5g 5g 5g Anti-settling agent 3g 3g 3g 3g negative ion powder 100g 80 50g 25g Nano Aluminum Hydroxide 100g 80g 50g 25g matting powder 30g 30g 30g 30g wax powder 5g 1g 2g 3g

[0027]

[0028] Operate the production process through this experiment, first put 50 g of photoinitiator 1-hydroxyalkylhexyl benzophenone and 200 g of tripropylene glycol diacry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com