Graphene composite, application of graphene composite to catalytic methanol oxidation, chemically modified electrode and preparation method of graphene composite

A technology for modifying electrodes and graphene, which is applied in the field of electroanalytical chemistry, can solve the problems of unsatisfied, lack of particle size and shape control of catalyst particles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The present invention preferably carries out the in-situ preparation of the above-mentioned graphene composite on the surface of the base electrode, and provides a preparation method of a modified electrode comprising the following steps:

[0043] a) coating the graphene dispersion on the surface of the ITO substrate electrode, and obtaining the graphene-modified ITO electrode after drying;

[0044] b) the graphene-modified ITO electrode is placed in a Prussian blue electrolyte, and the first electrochemical deposition obtains a Prussian blue-graphene-modified electrode;

[0045] c) placing the Prussian blue-graphene modified electrode in a chloroplatinic acid solution, and second electrochemical deposition to obtain the modified electrode described in the above technical scheme.

[0046]In the invention, the graphene dispersion liquid is coated on the surface of the ITO base electrode, and the graphene-modified TIO electrode is obtained after drying. In the present in...

Embodiment 1

[0067] Place the ITO in acetone, ethanol and deionized water in turn for 30 minutes, and finally rinse with deionized water and dry at room temperature;

[0068] Disperse graphene in deionized water and ultrasonically for 2 hours to obtain a graphene dispersion with a mass concentration of 1 mg / mL;

[0069] Apply 2 μL of the above graphene dispersion on the surface of the dried ITO, and dry it under an infrared lamp to obtain a graphene-modified ITO electrode (GN / ITO);

[0070] Immerse GN / ITO in a molar concentration of 2×10 -3 mol / L of K 3 [Fe(CN) 6 ] and a molar concentration of 2×10 -3 mol / L FeCl 3 In the electrodeposition solution, which also includes KCl with a molar concentration of 0.1 mol / L and HCl with a molar concentration of 0.01 mol / L as the electrolyte; a Prussian blue-graphene modified electrode was obtained by constant potential deposition at 0.4V for 60s ( PB / GN / ITO);

[0071] Rinse PB / GN / ITO with secondary water, and then place it in KCl with a mass conc...

Embodiment 2

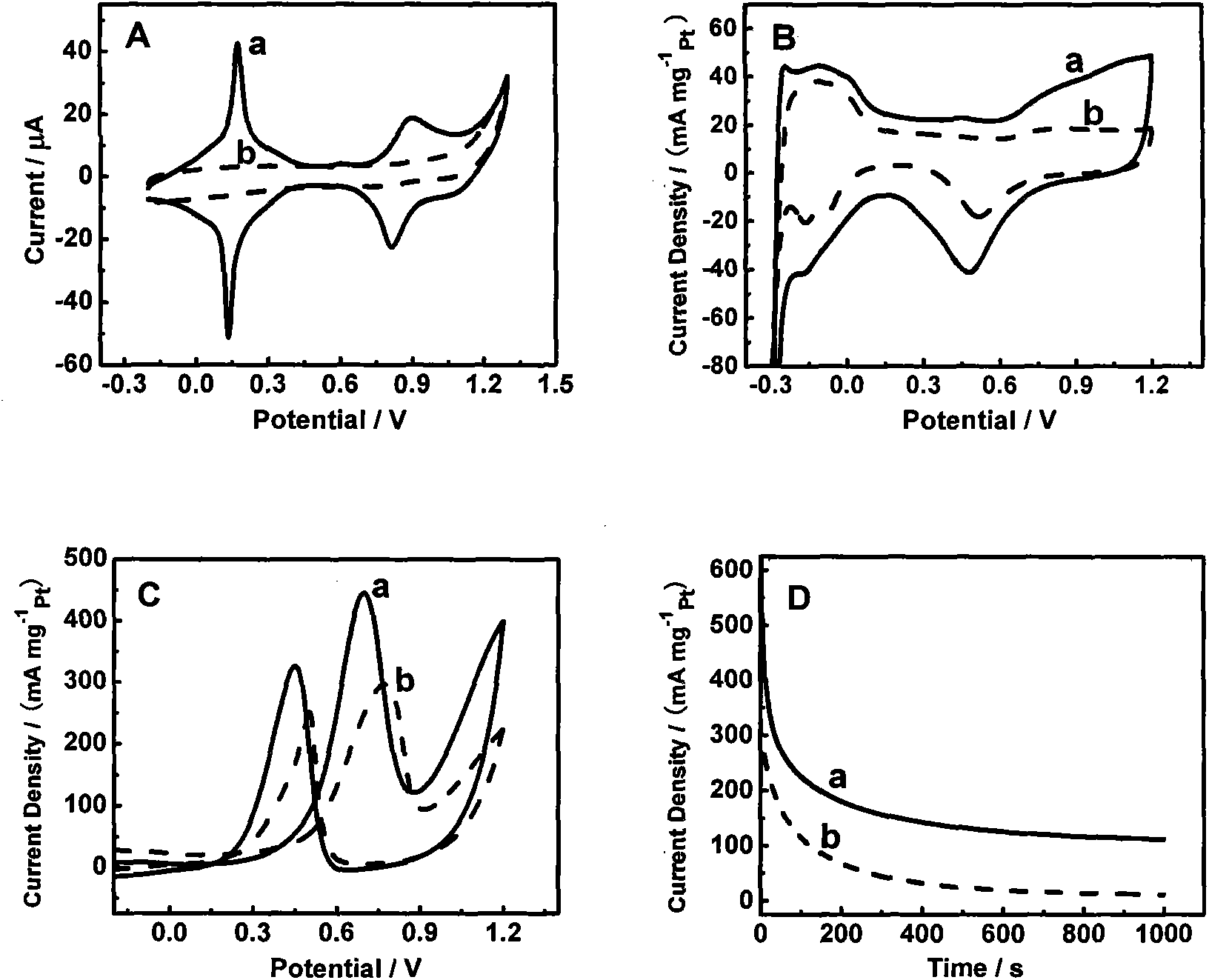

[0077] In the present invention, the Pt / PB / GN / ITO obtained in Example 1 is placed in an aqueous KCl solution with a molar concentration of 0.5 mol / L, and at a sweep rate of 50 mV / s, cyclic voltammetry is used to detect that the modified electrode has a concentration of 0.5 mol / L. Cyclic voltammetry curves in aqueous KCl solution of L.

[0078] The result is as image 3 As shown in A, image 3 A is the cyclic voltammetry curve that embodiment 2 of the present invention and comparative example 4 obtain, wherein image 3 A (a) is the cyclic voltammetry curve that the embodiment of the present invention 2 obtains, image 3 There are two pairs of redox peaks in A(a), which correspond to Prussian white / PB (0.17V / 0.13V) and PB / berlin green (0.90V / 0.82V), which are typical of PB. Redox peaks, the peak potential difference of the first pair of redox peaks is only 41mV, which shows that the electron transfer process in Pt / PB / GN / ITO is faster.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com