A method for reducing and degrading organic pollutants by Al-Ni alloy in alkaline wastewater

A technology of organic pollutants and aluminum-nickel alloys, applied in the direction of reduced water/sewage treatment, etc., can solve the problems of high cost, decreased catalytic activity, increased operation difficulty and danger, etc., and achieves low cost, wide range of sources, increased catalytic processing The effect of hydrogen reduction on the ability to degrade organic pollutants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

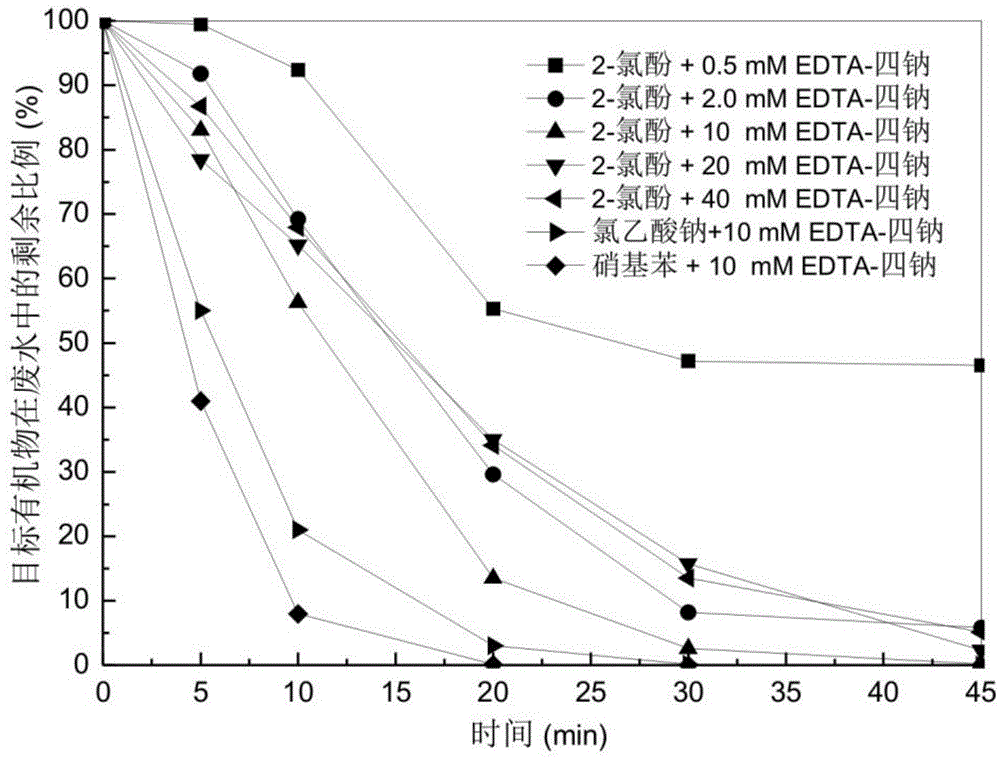

[0028] Embodiment 1: Aluminum-nickel alloy carries out hydrogenation reduction degradation of chlorinated organic wastewater under EDTA-tetrasodium complexation

[0029] First, put conventional commercial aluminum-nickel alloy (provided by Sinopharm Chemical Reagent Co., Ltd., nickel content is 40-50wt.%, the rest is aluminum) particles into the wastewater, and control the dosage of aluminum-nickel alloy at 1-20g / L ;

[0030] Secondly, add EDTA-tetrasodium, and the dosage is in the range of 1:0.05 to 1:4 (g:mM) according to the ratio of the “gram” mass of aluminum-nickel alloy to the “millimoles” of EDTA-tetrasodium. For the water phase In the dechlorination degradation reaction of chlorinated organic pollutants, the proportion of complexing agent can be increased with the increase of the amount of aluminum-nickel alloy; again, the dechlorination degradation reaction is carried out under normal temperature and pressure stirring conditions to strengthen mass transfer and preven...

Embodiment 2

[0032] Example 2: Nitrobenzene wastewater hydrogenation reduction degradation of aluminum-nickel alloy under EDTA-tetrasodium complexation

[0033] The reaction performance evaluation conditions of aluminum-nickel alloy particles under the action of EDTA-tetrasodium are basically the same as in Example 1, except that nitrobenzene wastewater is used, the volume is 100mL, and its initial concentration is 100mg / L, and 1g of aluminum-nickel alloy is put into Particles (particle size 100 mesh) and EDTA-tetrasodium with a final concentration of 10mM, the initial pH value of the solution was 11.0, stirred and reacted, water samples were taken during the gas chromatography analysis, the hydrogenation degradation reaction of nitrobenzene proceeded rapidly, and the reaction After 15 minutes, nitrobenzene is completely degraded, and the product is mainly aniline. The reaction effect is as follows: figure 1 shown.

Embodiment 3

[0034] Embodiment 3: Aluminum-nickel alloy carries out hydrogenation reduction degradation of high-concentration sodium chloroacetate wastewater under EDTA-tetrasodium complexation

[0035] The reaction performance evaluation conditions of aluminum-nickel alloy particles under the action of EDTA-tetrasodium are basically the same as in Example 1, except that the waste water prepared by sodium chloroacetate is initially about 500mg / L, and the volume is 500mL, which is weakly alkaline. Solution, adjust its pH value to 10.5 with NaOH, put 10g of aluminum-nickel alloy particles (particle size 100 mesh) and EDTA-tetrasodium particles with a final concentration of 20mM, stir and react, during which the water sample is lipidified by sulfuric acid and methanol Afterwards, it was extracted by methyl tert-butyl ether and analyzed by gas chromatography (GC-ECD). Chloroacetic acid and methyl chloroacetate were not detected after 30 minutes of reaction (the detection limit of GC-ECD was 500...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com