Paenibacillussp and breeding method thereof as well as beta-glucanase produced from paenibacillussp and method for producing beta-glucanase

A Paenibacillus and glucanase technology, applied in the field of microorganisms, can solve the problems of low production level of β-glucan, insufficient source of strains, poor heat resistance, etc., and achieve easy observation and identification, easy operation, and high enzyme reaction Effect of temperature and temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1: Isolation and screening of β-glucanase producing bacteria S09 of the present invention

[0034] The rhizosphere soil samples of oats from the oat field in the suburbs of Nanjing were taken, added to the liquid screening medium for enrichment and cultured for 3 days, then the bacterial solution with a high degree of viscosity reduction was selected and diluted, and spread on the solid medium with Sola gum as the only carbon source. Cultured in a constant temperature incubator at 28°C. After 3 days, observe the growth of the colony, cover the medium with 2% CTAB solution, and observe the formation of the hydrolysis circle of Sola gum after 20 minutes. The Sola gum around the colony secreting β-glucanase was degraded and could not be combined with CTAB to become transparent, and the unhydrolyzed Sola gum combined with CTAB to form a white insoluble precipitate. The colony that formed the hydrolysis circle was reinoculated into the liquid medium, and cultured wi...

Embodiment 2

[0036] Embodiment 2: Paenibacillus S09 of the present invention ( Paenibacillus sp.S09) identification

[0037] a. Morphological characteristics: Observed after 2-4 days of culture on the inorganic salt sola gum solid medium at 28°C, the colony is light yellow and round, indicating smooth and moist, with neat edges.

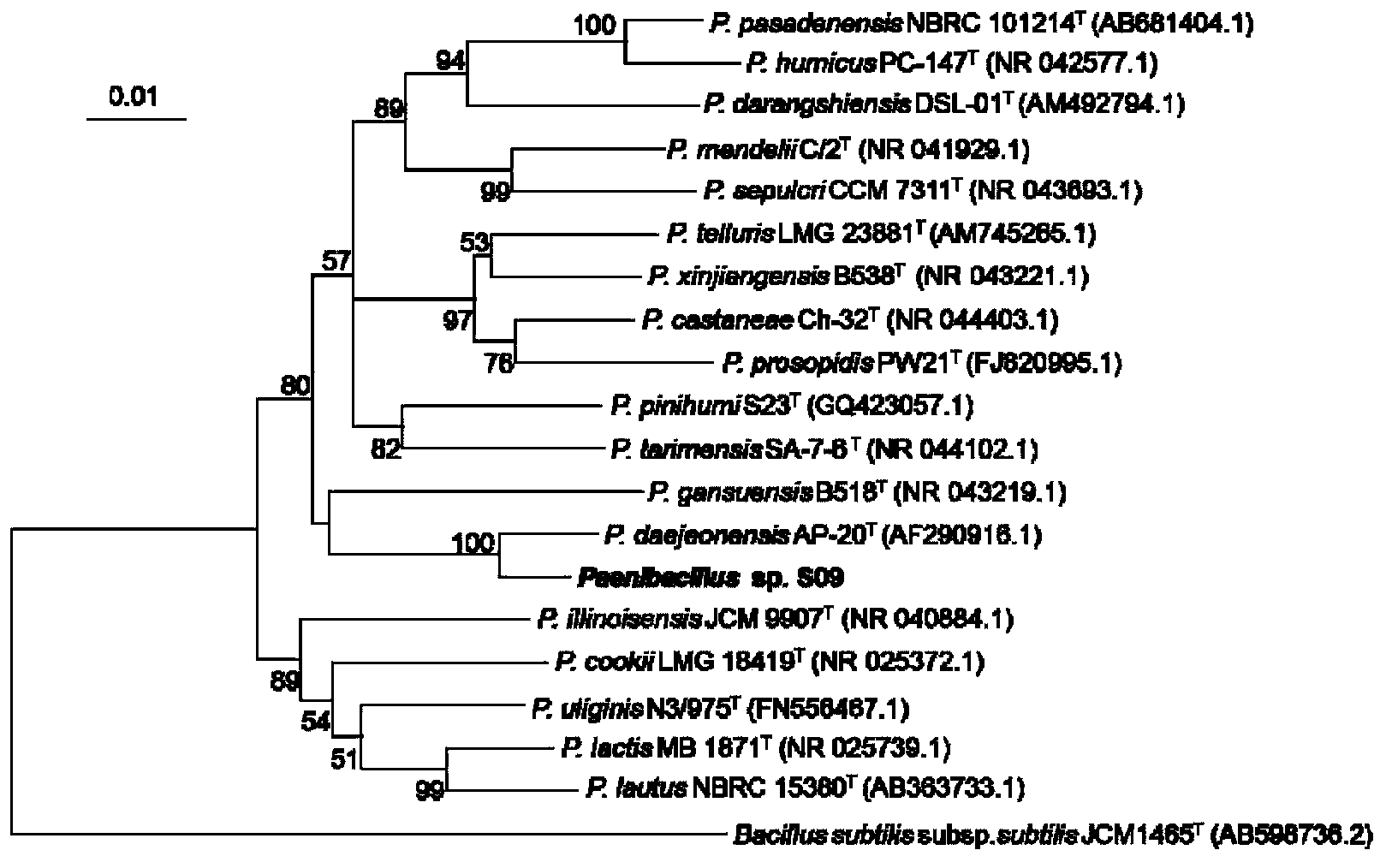

[0038] b. Physiological and biochemical characteristics: It can effectively reduce nitrate, cannot degrade cellulose, grows very slowly in LB medium, but can grow rapidly after adding β-glucan. figure 1 b is the scanning electron microscope image of S09, which is short rod-shaped, without flagella, about 0.5 μm × 2.5 μm in size, and Gram staining is negative. The bacterial strain is aerobic, and the optimum temperature for growth and enzyme production is 28-30°C, and can also grow at 37°C, and the optimum pH is 6.0-7.0.

Embodiment 3

[0039] Embodiment 3: the preparation of Paenibacillus S09 fermentation crude enzyme liquid

[0040] Prepared seed medium: KH 2 PO 4 1‰, NaNO 3 2.5‰, CaCl 2 0.1‰, MgSO 4 0.15‰, FeSO 4 ·7H 2 O 0.01‰, solar rubber 3‰, H 2 O1000mL, pH6.5. After the culture was sterilized under high pressure at 121°C for 20 minutes, it was cooled to room temperature, and a single colony of S09 on the inoculated solid medium was picked and cultured with shaking at 28°C for 3 days to form a seed solution.

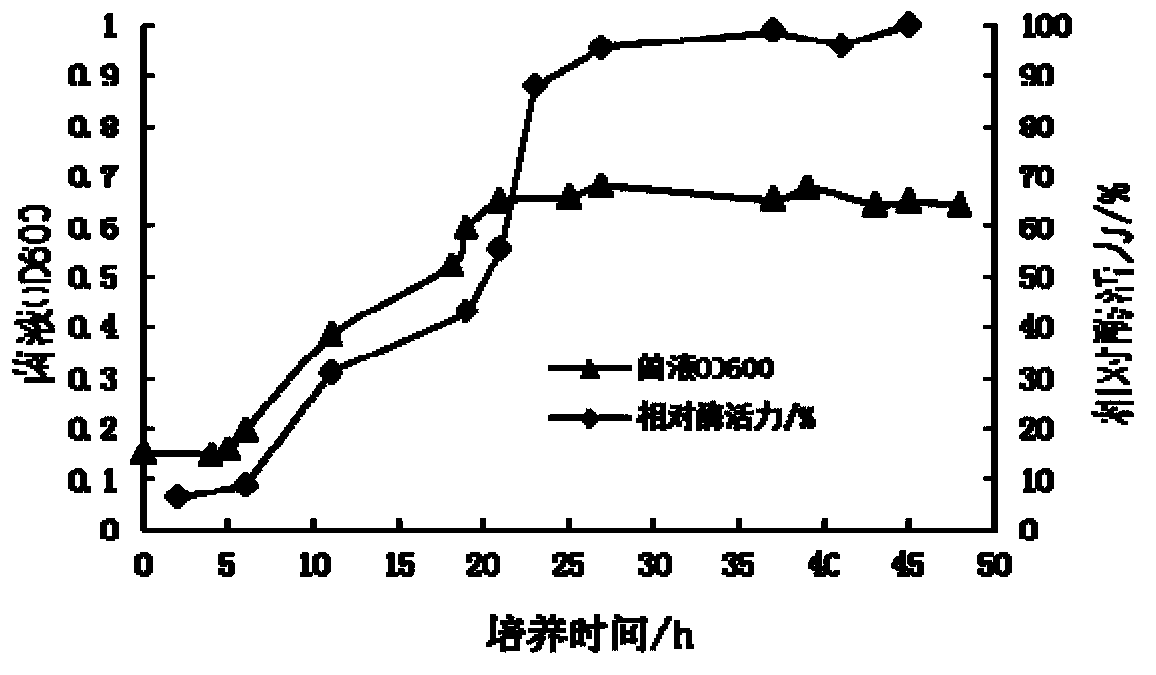

[0041] Prepare fermentation medium: 1% peptone, 0.5% yeast extract, 1% NaCl, 0.75% sola gum, pH6.5, sterilize the culture at 121°C for 20 minutes, cool to room temperature, and add 2% seed culture solution , 28°C, 220rpm, shaking culture for 30h, centrifuging at 7000rpm for 15min to remove the bacteria, collecting the supernatant to obtain a crude enzyme solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com