A method for preparing novel copper alloy protective layer material and film lamination

A technology of copper alloy and protective layer, which is applied in the application field of thin-film photovoltaic cells, and can solve problems such as poor weather resistance, disconnection, and electron migration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

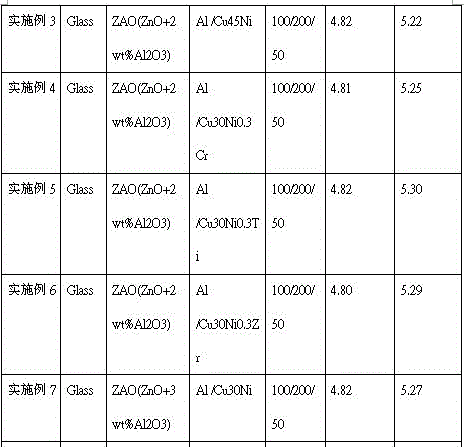

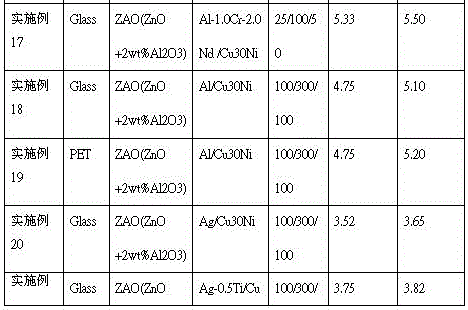

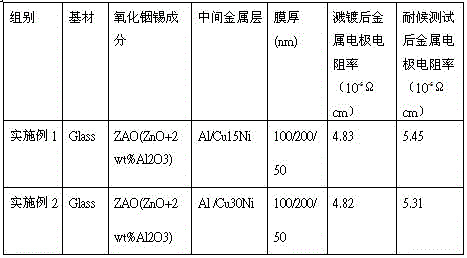

Embodiment 1

[0023] A method for preparing a novel copper alloy protective layer material and film lamination, adopting a multilayer structure design, firstly glass substrate (Corning 7095), pure aluminum target material, copper alloy (Cu-15wt%Ni) and zinc oxide aluminum ( ZnO+2wt%Al2O3) target material was placed in the vacuum sputtering machine, and the vacuum pumping system pumped the background pressure of the sputtering chamber to 0.7×10 -5 -0.9×10 -5 After torr, argon is used as the working gas, and argon is introduced through the throttle valve to control the working pressure of the sputtering chamber to be 3×10 -3torr, the glass substrate is not heated. Then sputter the first layer of 100nm thick zinc aluminum oxide (ZnO+2wt%Al2O3) film with DC power supply, the second layer of 200nm thick pure aluminum film, and the third layer of 50nm thick copper alloy (Cu-15wt%Ni) Thin film, that is, to form the required Glass / ZAO / Al / Cu-alloy multilayer film structure, use a four-point probe...

Embodiment 2

[0025] A method for preparing a new type of copper alloy protective layer material and film lamination, adopting a multi-layer structure design, first of all glass substrate (Corning 7095), pure aluminum target material, copper alloy (Cu-ˇ30wt%Ni) and zinc oxide aluminum ( ZnO+2wt%Al2O3) target material was placed in the vacuum sputtering machine, and the vacuum pumping system pumped the background pressure of the sputtering chamber to 0.7×10 -5 -0.9×10 -5 After torr, argon is used as the working gas, and argon is introduced through the throttle valve to control the working pressure of the sputtering chamber to be 3×10 -3 torr, the glass substrate is not heated. Then sputter the first layer of 100nm thick zinc aluminum oxide (ZnO+2wt%Al2O3) film with DC power supply, the second layer of 200nm thick pure aluminum film, and the third layer of 50nm thick copper alloy (Cu-30wt%Ni) Thin film, that is, to form the required Glass / ZAO / Al / Cu-alloy multilayer film structure, use a fo...

Embodiment 3

[0027] A method for preparing a novel copper alloy protective layer material and film lamination, adopting a multilayer structure design, first glass substrate (Corning 7095), pure aluminum target material, copper alloy (Cu-45wt%Ni) and zinc oxide aluminum ( ZnO+2wt%Al2O3) target material was placed in the vacuum sputtering machine, and the vacuum pumping system pumped the background pressure of the sputtering chamber to 0.7×10 -5 -0.9×10 -5 After torr, argon is used as the working gas, and argon is introduced through the throttle valve to control the working pressure of the sputtering chamber to be 3×10 -3 torr, the glass substrate is not heated. Then sputter the first layer of 100nm thick zinc aluminum oxide (ZnO+2wt%Al2O3) film with DC power supply, the second layer of 200nm thick pure aluminum film, and the third layer of 50nm thick copper alloy (Cu-45wt%Ni) Thin film, that is, to form the required Glass / ZAO / Al / Cu-alloy multilayer film structure, use a four-point probe ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com