Boiler cleaning agent

A cleaning agent and boiler technology, applied in the field of chemical preparations for boiler cleaning, can solve the problems of long cleaning time, difficult environmental protection requirements, complicated cleaning process, etc., and achieve the effect of short cleaning time and low corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Weigh 0.11 mol of o-phenylenediamine and 0.05 mol of sebacic acid, grind them thoroughly in a mortar to mix them uniformly, and transfer them to a three-necked flask. Add 20 mL of commercially available hydrochloric acid, 5 mL of commercially available phosphoric acid, and 75 mL of deionized water to form a mixed acid, pass nitrogen, and heat to reflux under mechanical stirring for reaction. TLC tracking and monitoring until the end of the reaction, about 10h, pour it into a 250mL beaker, let it stand for cooling, and adjust the pH=7 with concentrated ammonia water. Stand overnight at 4°C, filter and dry with suction, and recrystallize the obtained crude product with methanol / water to obtain a pure product.

Embodiment 2

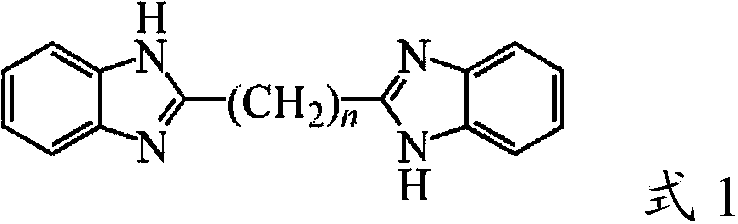

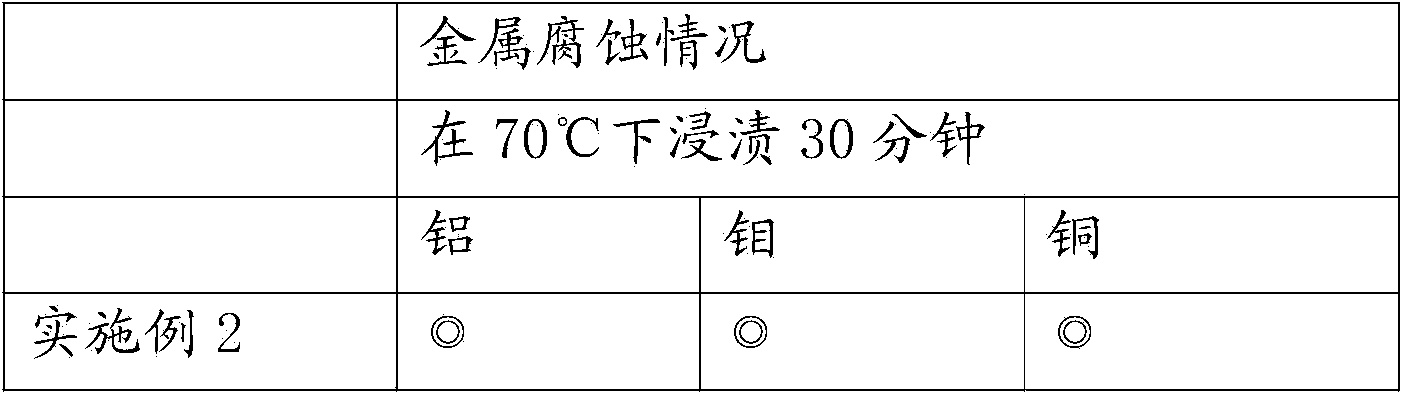

[0033] Dissolve 4 g of disodium salt of EDTA in 100 g of water, add 1 g of octylphenol polyoxyethylene ether with a degree of polymerization of 10, 2 g of polyacrylic acid, 1 g of cetyl dimethyl benzyl ammonium chloride, 8 g of citric acid, and , 2.5 g of ω'-bis(benzimidazol-2-yl)alkane, 2.5 g of hydrazine hydrate, 1 g of hydrogen peroxide and 6 g of ethanol were stirred for 40 minutes to obtain a cleaning agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com