Carrier brightening agent as well as preparation method and application thereof

A technology of carrier brightener and linking agent, applied in the field of carrier brightener and its preparation, can solve the problems of reduced dispersibility, insufficient brightness, poor tolerance and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

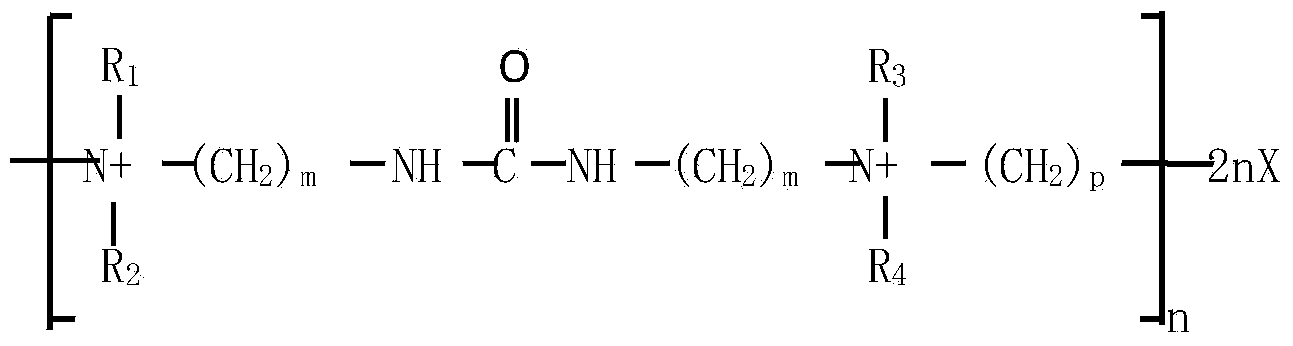

Method used

Image

Examples

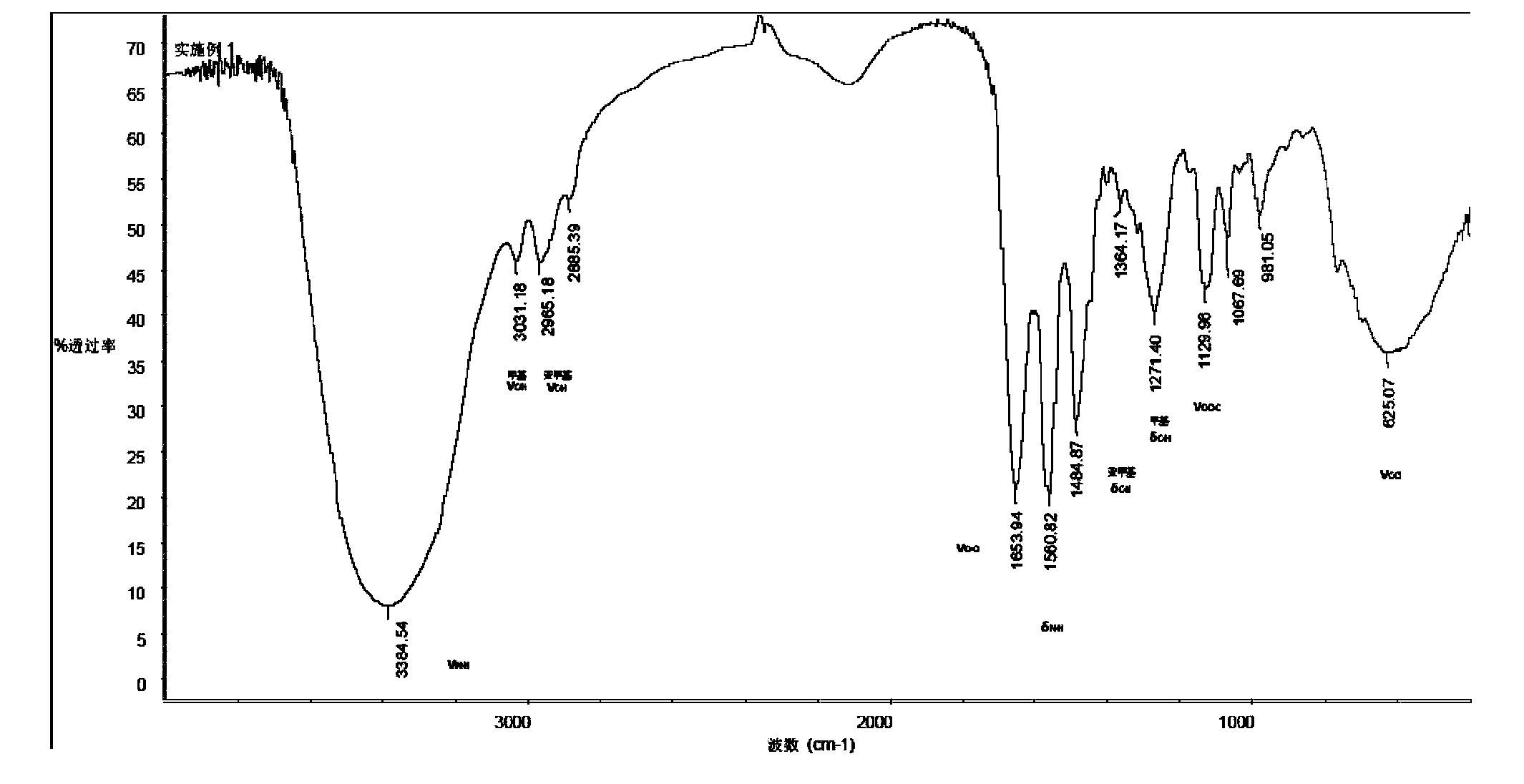

Embodiment 1

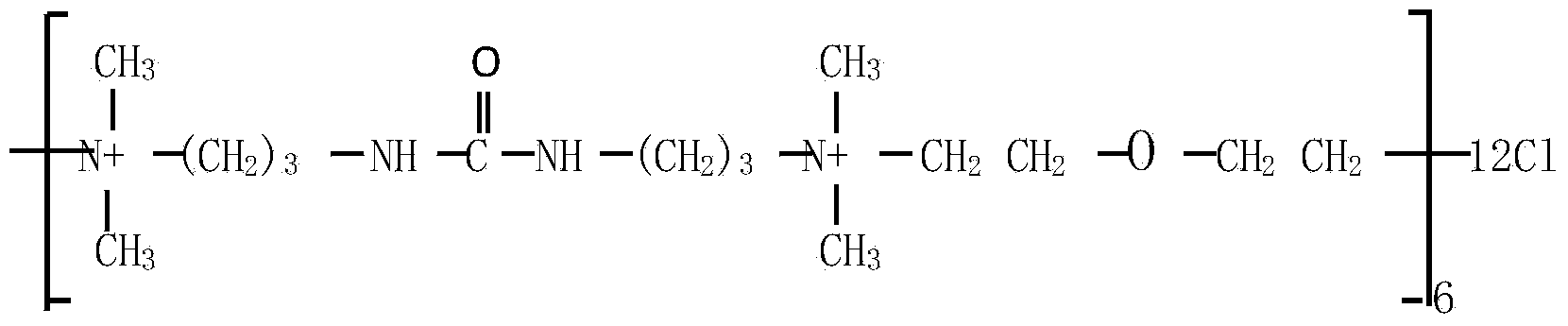

[0098] The carrier brightener provided in this embodiment, the carrier brightener is a random co-condensation polymer, the components participating in the co-condensation, solvent and alkaline substance and the preparation process are as follows:

[0099] Add 82 grams (0.35 moles) of N,N'-bis[3-(dimethylamino)propyl]urea, 34 grams (0.15 moles) of N-[3-(dimethylamino)propyl]-N'-phenylurea mol), water 200 g, and sodium hydroxide 6 g (0.15 mol) were added to a reaction flask equipped with a reflux condenser, thermometer, stirrer, and separatory funnel feeder. Heat until reflux occurs, add 46.8 grams of 2,2′-dichlorodiethyl ether (0.32 moles) and 16.2 grams of 1,4-dichlorobutane (0.13 moles) dropwise from the separatory funnel successively, at a speed that can be stabilized Reflux is in degrees. After adding the linking agent, keep a steady reflux until the reflux is clear and free of oil, then keep warm for 1 hour, stir the whole process, and get the reaction product after cooli...

Embodiment 2

[0101] The carrier brightener provided in this embodiment is a random co-condensation polymer, and the following four components, solvents and alkaline substances are mainly involved in the co-condensation:

[0102]

[0103] The preparation method of the above-mentioned carrier brightener is the same as in Example 1, and the reaction product (effective concentration is about 44%) is obtained after cooling. The infrared spectrum of the dry product in this example shows that it is similar to that of Example 1, so it is not provided here.

Embodiment 3

[0105] The carrier brightener provided in this embodiment is a random co-condensation polymer, and the following three components, solvents and alkaline substances are mainly involved in the co-condensation:

[0106]

[0107] The preparation method of the above-mentioned carrier brightener is the same as in Example 1, and the reaction product (effective concentration is about 48.7%) is obtained after cooling. The infrared spectrum of the dry product in this example shows that it is similar to Example 1, and is not provided here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com