Technique for reducing in-vivo decomposition and absorption speed of starch

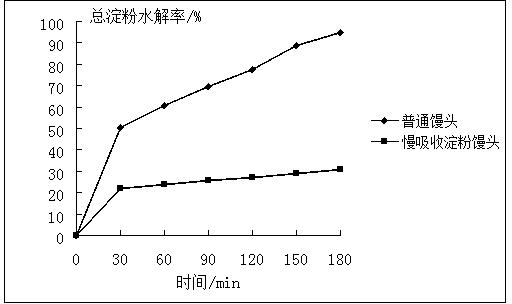

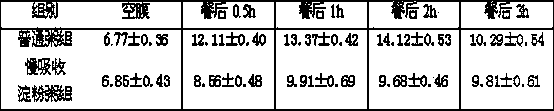

A technology for decomposing and absorbing starch, applied in the directions of non-active ingredients medical preparations, medical preparations containing active ingredients, organic active ingredients, etc. Post-glycemia, improving quality of life, and reducing complications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Mix 10 kg of soybean starch and wheat starch with a particle size of 100 mesh and 2 kg of mulberry leaf extract for later use; disperse 0.07 kg of sodium carboxymethyl cellulose in 3.5 kg of cold water, make it fully absorb water and swell until it is completely dissolved, and then add 2.5kg of water, after mixing, add it to the raw material powder and stir evenly to form a soft material, put it into a twin-screw extruder, make it into a rice shape through a mold, and then microwave dry until the water content is 2.5%.

Embodiment 2

[0039] Mix 10kg of mung bean starch with a particle size of 90 mesh, 20kg of rice flour and 1.5kg of Polygonatum odoratum extract for later use; disperse 0.2kg of guar gum and 0.1kg of sodium alginate in 5kg of cold water and stir evenly to make it fully absorb water and swell Until it is completely dissolved, add 6kg of water, mix it and add it to the raw material powder and stir it evenly to form a soft material, put it into a twin-screw extruder, make it into a mung bean shape through a mold, and dry it in a fluidized bed until the water content is 3.0%. That's it.

Embodiment 3

[0041] Pueraria puerariae and Chinese chestnut are crushed into fine powder with a particle size of 100 mesh, and 3 kg of each is mixed with 14 kg of wheat starch with a particle size of 90 mesh and 2 kg of Digupi extract for later use; 0.2 kg of carrageenan is dispersed in 4 kg of cold water and stirred evenly. Make it fully absorb water and swell until it is completely dissolved, then add 3.5kg of water, mix well, add raw material powder and stir well to form a soft material, put it into a twin-screw extruder, make it into a millet shape through a mold, and dry it with hot air until it reaches moisture 2.3% can be.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com