Flux-cored wire for stainless steel welding

A technology of flux-cored welding wire and stainless steel, which is applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc., and can solve problems such as low deposition efficiency, high requirements for welding equipment, and inconvenient construction and operation on site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

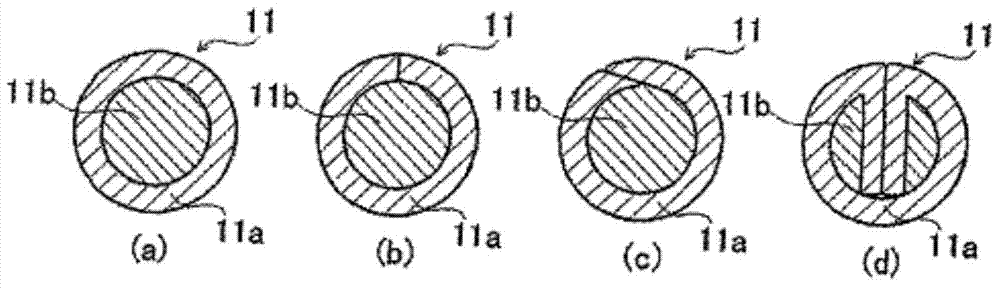

Image

Examples

Embodiment 1

[0065] Embodiment 1: Preparation of flux-cored welding wire of the present invention

[0066] The drug core powder is filled in the stainless steel strip (304L stainless steel) with a filling rate of 18%, and the contained drug core mass percentage composition is as follows:

[0067] 32% metal chromium powder, 8% metal nickel powder, 6% metal manganese powder, 25% rutile, 4% ferrosilicon, 5% ferrosilicon, 6% feldspar, 7% quartz, 3 % of rare earth fluoride, 1% of metal nickel nitride powder, and the rest is iron powder so that it can be added to 100%.

[0068] Flux-cored welding wire is obtained by rolling and drawing. The flux-cored wire uses a variety of shielding gases (100% CO 2 Gas, 80%Ar+20%CO 2 Mixed gas, 100% Ar) were used to weld the magnesium smelting reduction tank respectively, and the chemical composition of the deposited metal after welding with the welding wire contained (%): C: 0.09, Mn: 1.86, Si: 0.70, S: 0.009, P : 0.025, Cr: 25.85, Ni: 7.55, N: 0.09, Mo...

Embodiment 2

[0069] Embodiment 2: Preparation of the flux-cored welding wire of the present invention

[0070] The drug core powder is filled in the stainless steel strip (304L stainless steel) with a filling rate of 20%, and the contained drug core mass percentage composition is as follows:

[0071] 36% metallic chromium powder, 8% metallic nickel powder, 5% metallic manganese powder, 25% rutile, 2% ferrosilicon, 4% ferrotitanium, 6% feldspar, 6% quartz, 3 % of rare earth fluoride, 2% of metal chromium nitride powder, and the rest is iron powder so that it can be added to 100%.

[0072] Flux-cored welding wire is obtained by rolling and drawing. The flux-cored wire uses a variety of shielding gases (100% CO 2 Gas, 80%Ar+20%CO 2 Mixed gas, 100% Ar) were used to weld the magnesium smelting reduction tank respectively, and the chemical composition of the deposited metal after welding with the welding wire contained (%): C: 0.093, Mn: 1.93, Si: 0.62, S: 0.007, P : 0.023, Cr: 26.23, Ni: ...

Embodiment 3

[0073] Embodiment 3: Preparation of flux-cored welding wire of the present invention

[0074] The drug core powder is filled in the stainless steel strip (304L stainless steel) with a filling rate of 19%, and the contained drug core mass percentage composition is as follows:

[0075] 35% metal chromium powder, 8% metal nickel powder, 5% metal manganese powder, 30% rutile, 3% ferrosilicon,

[0076] 4% ferro-titanium, 7% feldspar, 6% quartz, 1% rare earth fluoride, 1% chromium nitride metal powder.

[0077] Flux-cored welding wire is obtained by rolling and drawing. The flux-cored wire uses a variety of shielding gases (100% CO 2 Gas, 80%Ar+20%CO 2 Mixed gas, 100% Ar) were used to weld the magnesium smelting reduction tank respectively, and the chemical composition of the deposited metal after welding with the welding wire contained (%): C: 0.09, Mn: 1.90, Si: 0.67, S: 0.006, P : 0.020, Cr: 26.31, Ni: 7.58, N: 0.086, Mo: 0.07, Cu: 0.08, and the balance of Fe and optional u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com