Preparation method of nano ferric oxide (Fe2O3) for acetone gas sensor material

A nano-iron trioxide, gas sensor technology, applied in nanotechnology for materials and surface science, iron oxide, iron oxide/iron hydroxide, etc., can solve the problems of incompatibility, high gas sensitivity and fast response, etc. Achieving the effect of high gas sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Example 1: Using ordered mesoporous silica MCM-41 as a hard template, add it to an ethanol solution of ferric nitrate (the solution concentration is not limited) and stir and impregnate, so that ferric nitrate is immersed in the mesoporous channels of silica, Then dry and evaporate the solvent, and calcine at 300°C in an atmosphere of sufficient air circulation to transform the iron precursor into Fe 2 o 3 , and then use 2M concentration of sodium hydroxide solution to stir and centrifuge to remove the silica template to obtain the desired nano-Fe 2 o 3 Gas-sensitive material (the masses of the hard template and the iron precursor are 4g and 0.2g respectively, and the mass ratio is 20).

[0019] Then prepare nano-Fe 2 o 3 Apply the slurry, and use a paint pen to evenly coat the slurry on the outer surface of the ceramic tube core with gold electrodes to form nano-Fe 2 o 3 The thickness of the sensing layer is 50um. After the coating is completed, it is dried under...

Embodiment 2

[0020] Example 2: Using ordered mesoporous silica KIT-6 as a hard template, add it to an aqueous solution of ferric chloride (the concentration of the solution is not limited) and stir and impregnate it, so that ferric chloride can be immersed in the mesoporous channels of silica , then dry and evaporate the solvent, and calcine at 500°C in an atmosphere of sufficient air circulation to transform the iron precursor into Fe 2 o 3 , and then use 2M concentration of sodium hydroxide solution to stir and centrifuge to remove the silica template to obtain the desired nano-Fe 2 o 3 Gas-sensitive material (the masses of the hard template and the iron precursor are 1 g and 2 g respectively, and the mass ratio is 0.5).

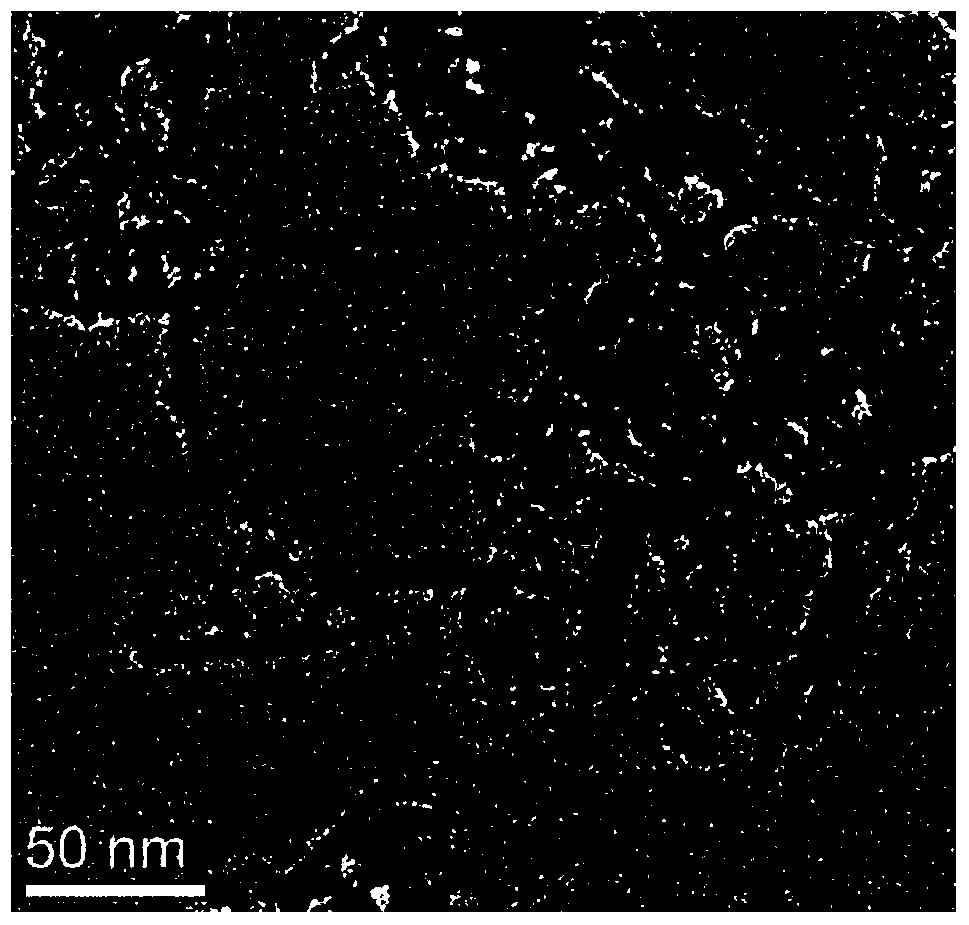

[0021] figure 2 For the prepared nano-Fe 2 o 3 TEM photographs of the prepared Fe 2 o 3 Has a rod-like nanostructure morphology; then formulate nano-Fe 2 o 3 Apply the slurry, and use a paint pen to evenly coat the slurry on the outer surface of the ceramic t...

Embodiment 3

[0022] Example 3: Using ordered mesoporous silica SBA-15 as a hard template, add it to an ethanol solution of ferric sulfate (the concentration of the solution is not limited) and stir and impregnate, so that ferric sulfate is immersed in the mesoporous channels of silica, Then dry and evaporate the solvent, and calcine at 800°C in an atmosphere of sufficient air circulation to transform the iron precursor into Fe 2 o 3 , and then use 2M concentration of sodium hydroxide solution to stir and centrifuge to remove the silica template to obtain the desired nano-Fe 2 o 3 Gas-sensitive material (the masses of the hard template and the iron precursor are 1 g and 5 g respectively, and the mass ratio is 0.2).

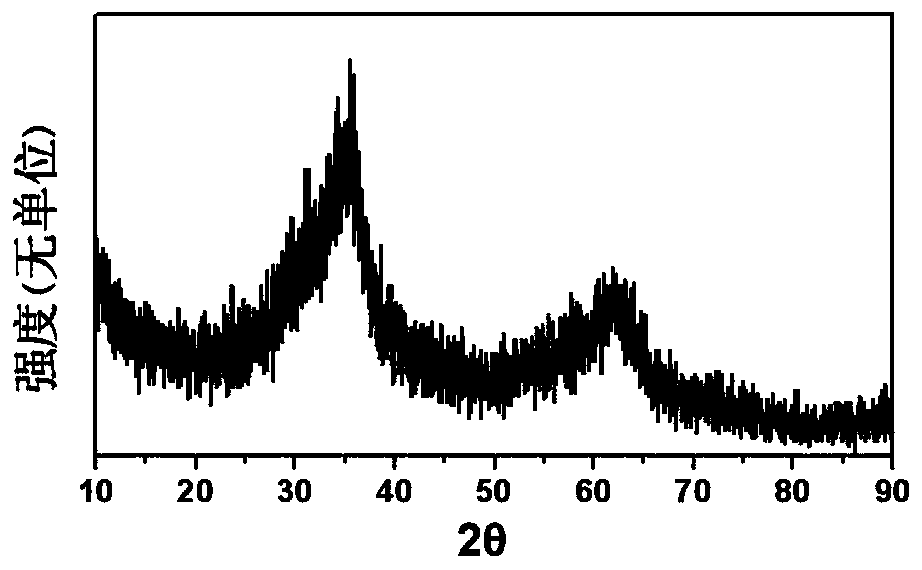

[0023] image 3 For the prepared nano-Fe 2 o 3 The XRD photo of the prepared Fe 2 o 3 Has an amorphous nanostructure; then formulates nano-Fe 2 o 3 Apply the slurry, and use a paint pen to evenly coat the slurry on the outer surface of the ceramic tube core with gold e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com