Printing and dyeing wastewater removal system

A technology of printing and dyeing wastewater and constant temperature water bath, which is applied in textile industry wastewater treatment, adsorption water/sewage treatment, oxidized water/sewage treatment, etc. It can solve the problems of low ozone utilization rate and high operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

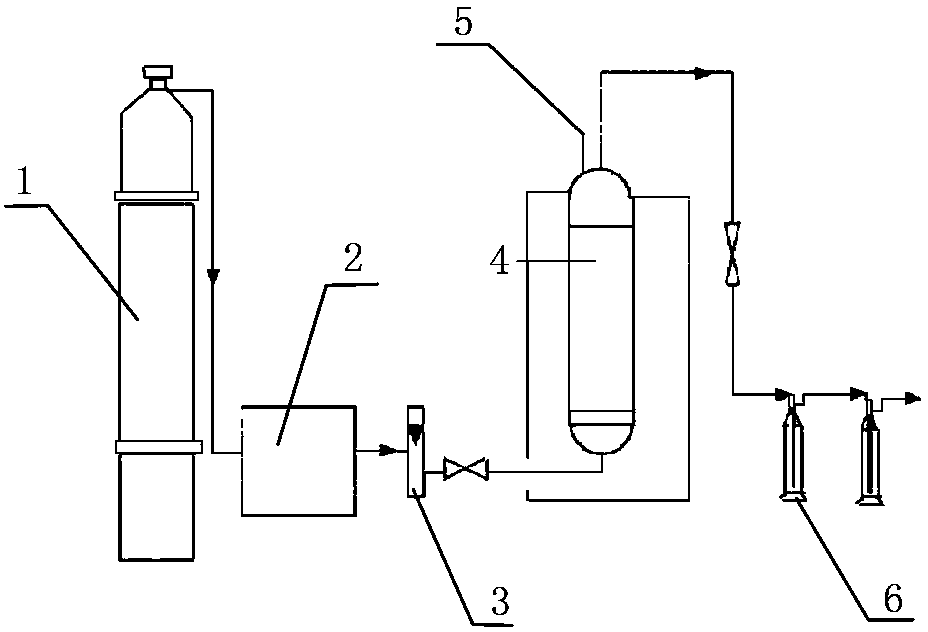

[0011] Such as figure 1 As shown, the printing and dyeing wastewater removal system consists of an oxygen tank 1 , an ozone generator 2 , a reactor 4 and an absorption bottle 6 connected in sequence. Reactor 4 is a columnar glass material with an inner diameter of 5 cm. Clear height 45 cm. The net volume is 0.8 L, immersed in a constant temperature water bath. A porous sand core plate (pore diameter 15-40 μm) is provided at the bottom of the reactor 4 to allow the gas to enter evenly. The model of ozone generator 2 is CHY-6, and oxygen is the gas source.

[0012] When in use, add waste water and 200mg / L activated carbon to reactor 4, adjust the reaction pH to 6.0, keep the reaction temperature at 25°C, and at the same time pass pure oxygen and tap water into ozone generator 2, and pass the prepared ozone into the reaction system . The ozone flow rate is controlled by the flowmeter 3 to be 50mL / min and enters the reactor 4 to react with the waste water, and the ozone in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com