Anaerobic alginate decomposing bacterium and application thereof

A technology of alginate decomposing bacteria and alginate lyase, which is applied in the direction of bacteria, lyase, microorganisms, etc., can solve the problems of limiting the large-scale application of alginate oligosaccharides, the lack of specificity in acid hydrolysis, and the inability to effectively control oligosaccharides. Achieve high enzyme production, avoid bacterial contamination, and shorten the time period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Example 1: Screening and isolation of anaerobic strain SH-52

[0041] The seabed sediment collected from the coast of Shantou City, Guangdong Province was diluted 1:10 (W / V), and inoculated into a 250ml anaerobic reagent bottle containing 100ml of modified marine medium (the carbon source was 10g / L sodium alginate ), cultured at 30°C, and transferred to fresh anaerobic modified marine medium after two days of cultivation, cultured to absorbance OD=0.8, transferred to fresh test tube medium, and inoculated three times (inoculum size: 2%). The culture was serially diluted (10 -1 、10 -2 、10 -3 、10 -4 、10 -5 、10 -6 ), using a Hunter roller tube (the culture medium is a modified marine medium, the carbon source is 10g / L sodium alginate, plus 1.5% agar) to separate, and pick a single colony to inoculate in the modified marine carbon source of sodium alginate In the culture medium, a strain capable of utilizing sodium alginate was screened out, numbered SH-52, and named ...

Embodiment 2

[0042] Embodiment 2: Physiological and biochemical detection

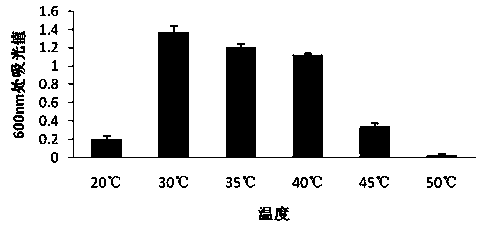

[0043] 1. Insert the bacterial strain obtained in Example 1 into the improved marine culture medium with a sodium alginate concentration of 10g / L at an inoculum size of 2%, at 20°C, 25°C, 30°C, 35°C, and 40°C respectively , 45°C, and 50°C culture, the measured temperature growth range of bacteria is 20°C to 45°C, and the optimum temperature is 30°C (see image 3 ).

[0044] 2. Configure the modified marine medium with pH gradients, the pH gradients are 5, 5.5, 6, 6.5, 7, 7.5, 8, 8.5, 9. The measured pH range of bacterial growth is 6 to 8.5, and the optimum growth pH is 7.5 (see Figure 4 ).

[0045] 3. Configure the NaCl concentration gradient to improve the marine medium, and the NaCl concentration gradient is 0%, 1%, 2%, 3%, 4%, 5%, 6%, 7%, 8%, 9%, 10% (w / v), the measured growth range of bacteria on the NaCl concentration gradient medium is 0% to 9%, and the optimum growth concentration is 2% (see Figu...

Embodiment 3

[0049] Example 3: Preparation of Alginate Lyase Crude Enzyme Liquid

[0050] Insert the bacterial strain obtained in Example 1 into the anaerobic marine culture medium with a sodium alginate concentration of 10 g / L at an inoculum size of 2%, culture it statically at 30°C for 36 hours, and centrifuge at 10,000g for 10 minutes to collect the bacterial cells. Resuspend the bacteria in 50mM Tris-HCl buffer solution with pH 7.5, crush the bacteria with an ultrasonic breaker with a power of 200W, sonicate for 3s, pause for 3s, run for 8min, then centrifuge at 12000g for 15min, collect the supernatant, and obtain crude Enzyme solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com