Preparation method of Cr-doped TiO2 nanometer magnetic film with room-temperature ferromagnetic effect

A ferromagnetic effect and nano-magnetic technology, applied in the direction of surface reaction electrolytic coating, electrolytic coating, coating, etc., to achieve the effect of high controllability, low cost and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

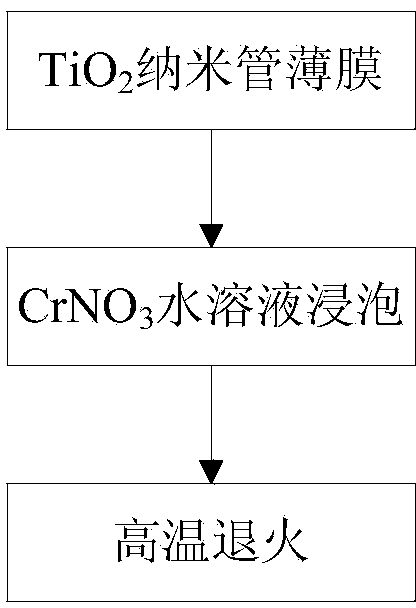

Method used

Image

Examples

Embodiment 1

[0025] 1) Dissolve a certain mass of ammonium fluoride in a mixed solution of ethylene glycol and deionized water with a volume ratio of 294:6 to make a mass percentage of ammonium fluoride of 2.4×10 -3 organic fluorine-containing electrolyte;

[0026] 2) Ultrasonic cleaning the metal titanium sheet with acetone, absolute ethanol and deionized water for 10 minutes respectively, and then drying it naturally for use;

[0027] 3) Then clamp and fix the cleaned titanium sheet as the anode, and place the platinum electrode parallel to it as the cathode to form an electrode system, and the distance between them is 2.5cm;

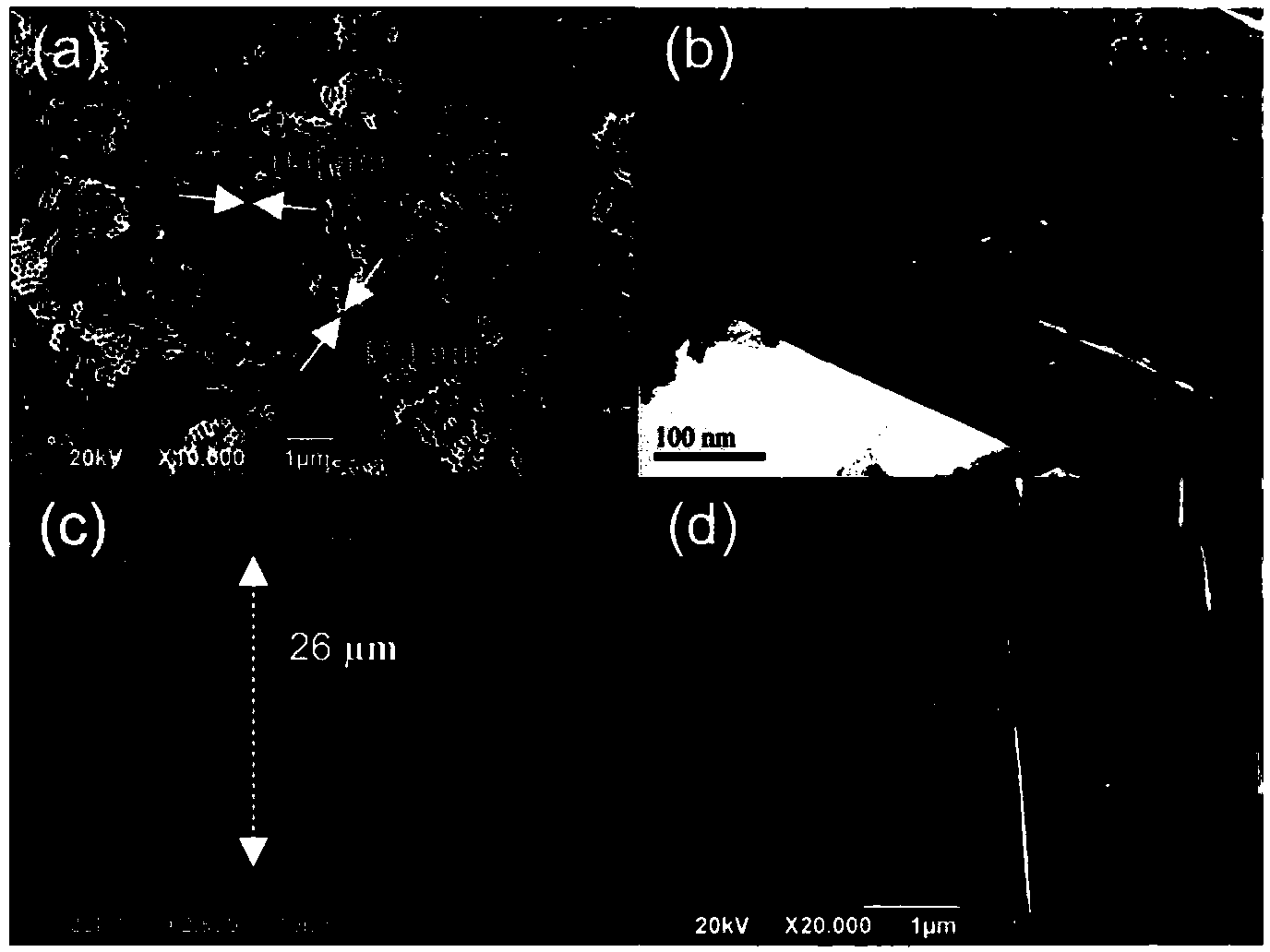

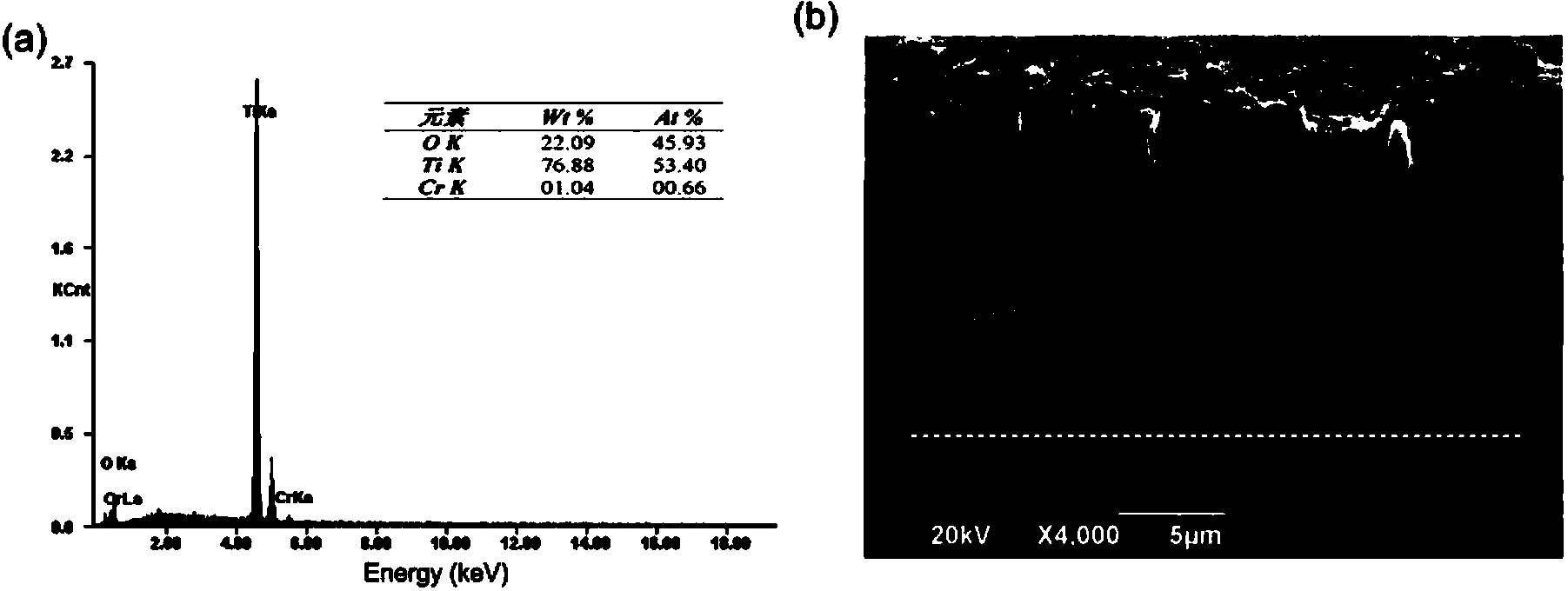

[0028] 4) Immerse the electrode system assembled as in step 3) into the electrolyte as in step 1), use a DC constant voltage source as the power supply, adjust the open circuit voltage directly from 0V to 60V, control the reaction temperature at 15°C, and react after 3 hours Obtaining Amorphous TiO on the Surface of Metal Titanium Sheet 2 nanotube film.

[0029...

Embodiment 2

[0033] 1) Dissolve a certain mass of ammonium fluoride in a mixed solution of ethylene glycol and deionized water with a volume ratio of 294:6 to make a mass percentage of ammonium fluoride of 3.6×10 -3 % organic fluorine-containing electrolyte;

[0034] 2) Ultrasonic cleaning the metal titanium sheet with acetone, absolute ethanol and deionized water for 10 minutes respectively, and then drying it naturally for use;

[0035] 3) Then clamp and fix the cleaned titanium sheet as an anode, and place a platinum electrode parallel to it as a cathode to form an electrode system, and the distance between them is 3cm;

[0036]4) Immerse the electrode system assembled as in step 3) into the electrolyte as in step 1), use a DC constant voltage source as the power supply, adjust the open circuit voltage directly from 0V to 60V, control the reaction temperature at 45°C, and react after 1 hour Obtaining Amorphous TiO on the Surface of Metal Titanium Sheet 2 nanotube film.

[0037] 5) A ...

Embodiment 3

[0041] 1) Dissolve a certain mass of ammonium fluoride in a mixed solution of ethylene glycol and deionized water with a volume ratio of 294:6 to make a mass percent of ammonium fluoride of 2.6×10 -3 % organic fluorine-containing electrolyte;

[0042] 2) Ultrasonic cleaning the metal titanium sheet with acetone, absolute ethanol and deionized water for 10 minutes respectively, and then drying it naturally for use;

[0043] 3) Then clamp and fix the cleaned titanium sheet as the anode, and place the platinum electrode parallel to it as the cathode to form an electrode system, and the distance between them is 2.5cm;

[0044] 4) Immerse the electrode system assembled as in step 3) into the electrolyte as in step 1), use a DC constant voltage source as the power supply, adjust the open circuit voltage directly from 0V to 60V, control the reaction temperature at 25°C, and react after 3 hours Obtaining Amorphous TiO on the Surface of Metal Titanium Sheet 2 nanotube film.

[0045]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com