Etching Method of Silicon Nitride High Aspect Ratio Hole

A high-aspect-ratio, silicon-nitride technology, applied in the manufacture of electrical components, circuits, semiconductors/solid-state devices, etc., can solve problems such as difficulty in obtaining etching morphology, low selectivity ratio, etch stop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below with reference to the accompanying drawings and taking specific embodiments as examples. However, those skilled in the art should know that the present invention is not limited to the specific embodiments listed, as long as it conforms to the spirit of the present invention, it should be included in the protection scope of the present invention.

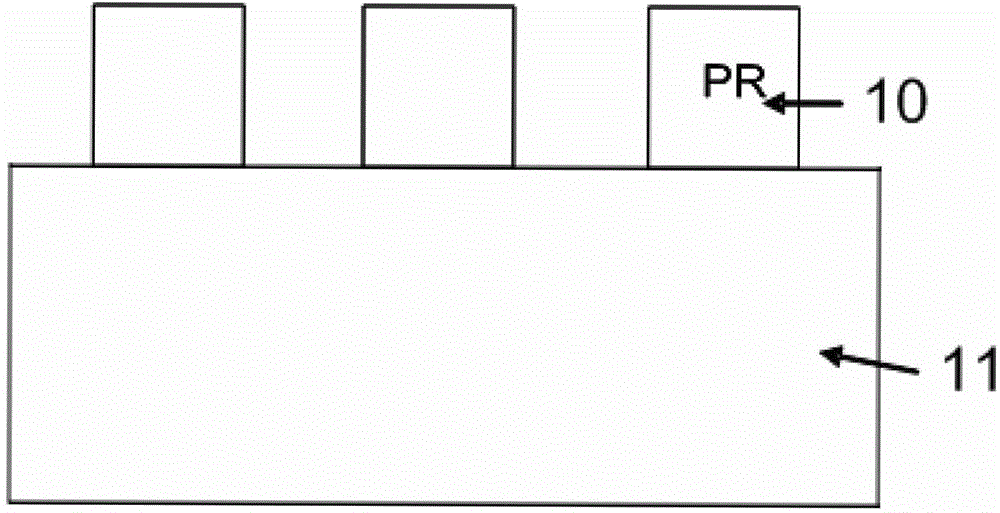

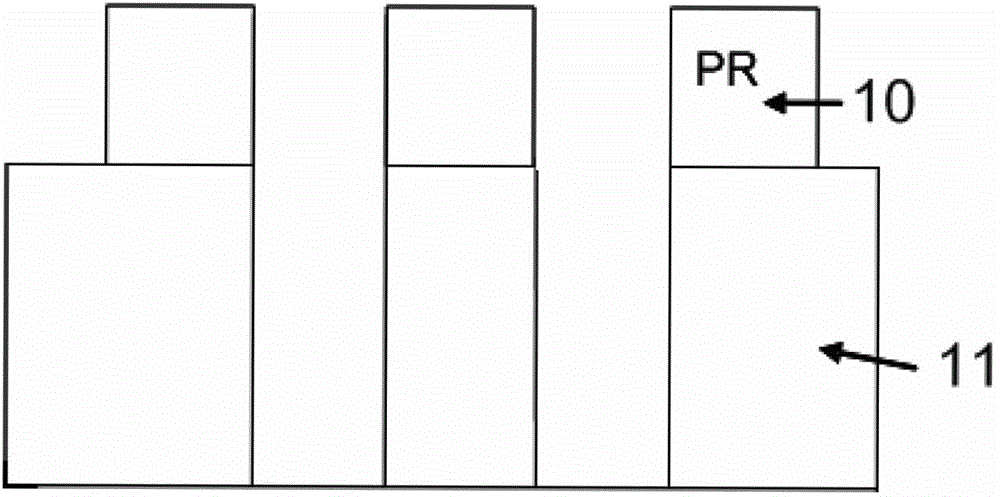

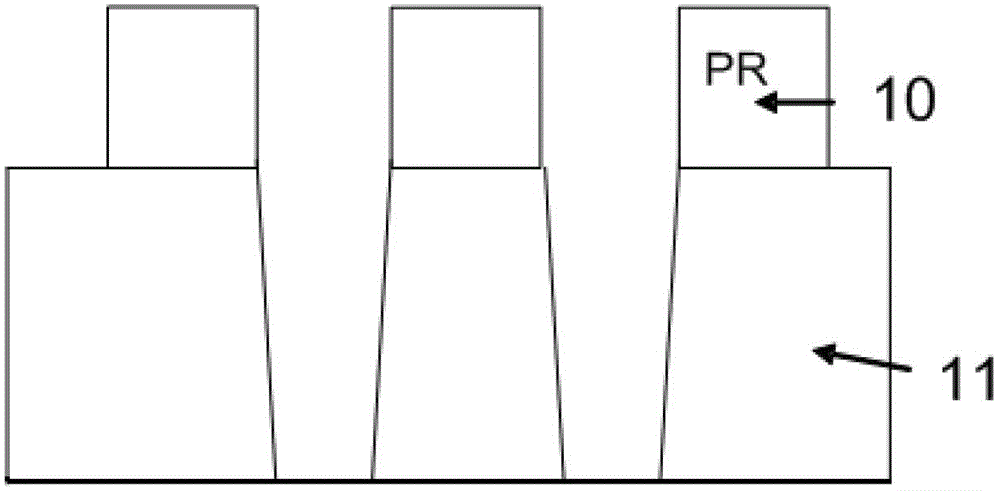

[0024] The etching method of the silicon nitride high aspect ratio hole of the present invention comprises the following steps:

[0025] First, put the wafer with the silicon nitride film structure with the desired pattern developed by photolithography into the etching chamber; The plasma is excited by adding a volatile gas, a hydrogen-containing fluorocarbon-based gas, and a radio frequency power; depth is required.

[0026] The high-carbon chain molecule fluorocarbon-based gas of the present invention can be obtained from C 4 F 6 , C 4 F 8 Select at least one of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com