Processing method for preserved fish

A processing method and a technology for dried fish meat, which are applied in the field of agricultural product processing, can solve the problems of low meat harvesting rate and heavy earthy smell of freshwater fish, and achieve the effects of reduced processing technology, less equipment investment and extended shelf life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

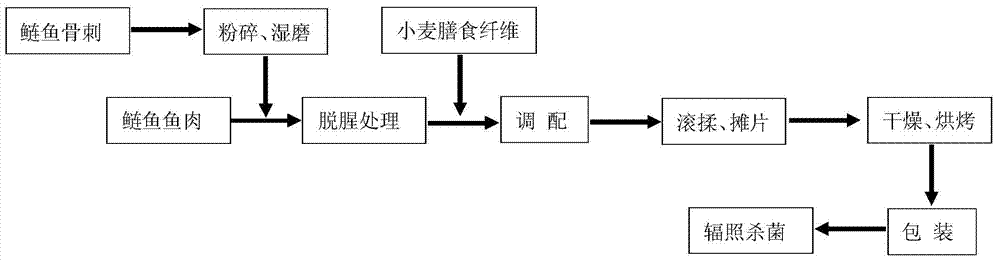

[0044] Processing method of dried fish meat:

[0045] (1) Raw material pretreatment: remove scales, gills and viscera of silver carp, obtain fish meat by sectioning, and grind it with a chopping machine; mix fish head, fish tail and fish bone spurs with water 1:1-1:3, It is processed into fish bone paste through a pulverizer and a bone paste mill.

[0046] (2) Deodorization process: The best deodorization conditions are salt solution concentration 60g / 1000mL, temperature 60 ℃, fish meat (or fish bone): brine 1:4 (w / w), soaking time 60min, take out and rinse with running water.

[0047] (3) Formula: Raw material ratio is 70% pure fish meat, 20% fish bone paste, 10% wheat dietary fiber; based on 1kg raw material, add 2% salt, 5% white sugar, 4% ginger juice, 5% white wine , 0.1% monosodium glutamate; spicy products add 0.08% five-spice powder, 0.1% pepper powder, 0.4% chili powder; garlic-flavored products add 0.5% garlic paste; pickled pepper-flavored products add 0.4% pickled...

Embodiment 2

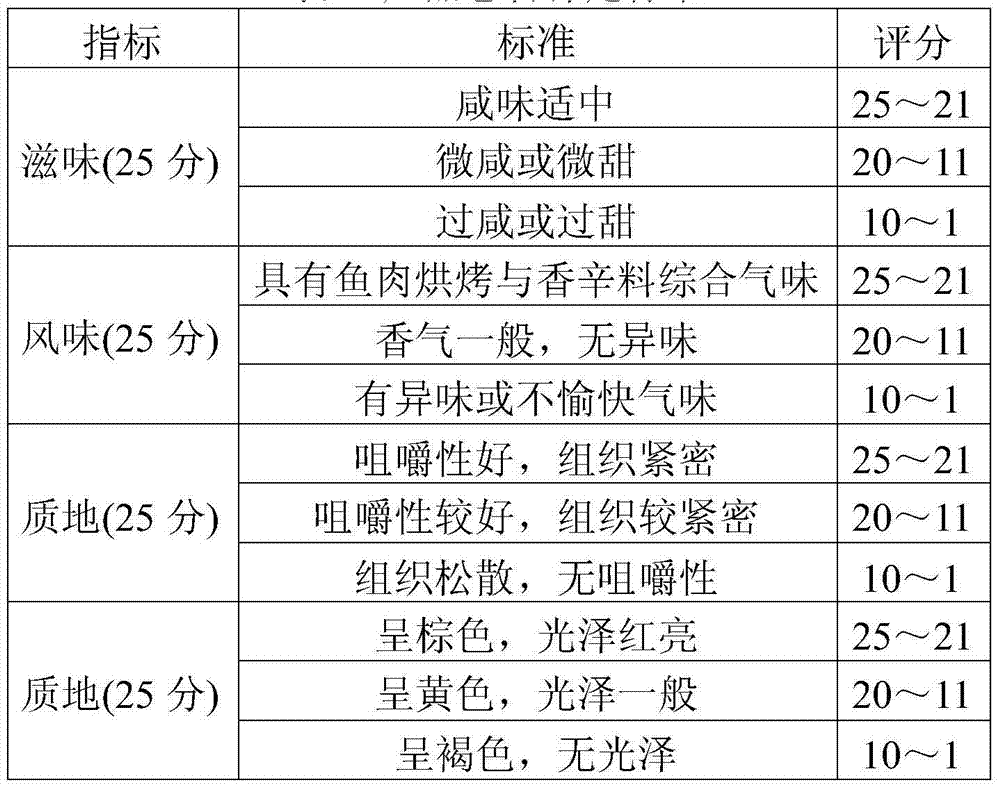

[0050] Sensory evaluation of different raw material ratios

[0051] Table 1 Product Sensory Evaluation Criteria

[0052]

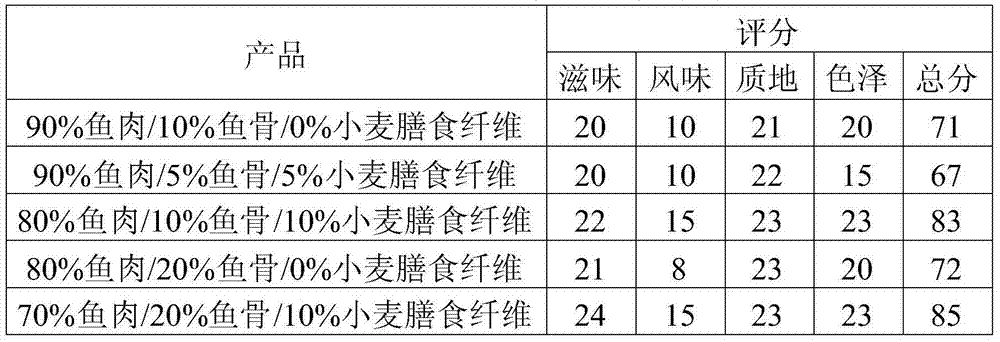

[0053] Table 2 Sensory evaluation table of dried fish products with different ratios

[0054]

[0055]

[0056]The dried fish products made by mixing different proportions of fish meat, fish bone and wheat dietary fiber were sensory evaluated from the four indicators of taste, flavor, texture and color, as shown in Table 2. It can be seen from the above table that the best evaluation result is 70 % fish meat / 20% fish bone / 10% wheat dietary fiber, 80% fish meat / 10% fish bone / 10% wheat dietary fiber, 70% fish meat / 10% fish bone / 20% wheat dietary fiber 3 groups. The sensory score of the product obtained by ingredients with a high proportion of fish meat is lower. This is because the fish protein is cross-linked into a dry gelatinous substance after being rolled and dried, and the texture is relatively hard, which affects the product sensory. In add...

Embodiment 3

[0058] Orthogonal test of deodorization process

[0059] Table 3 Level table of selection factors for deodorization conditions of fish meat and fish bones

[0060]

[0061] Table 4 Odor-removing Condition Selection Orthogonal Test Result

[0062]

[0063]

[0064] It can be seen from the range (R) in Table 4 that the primary and secondary order of the influence of the four factors on the deodorization effect of fish meat is C>A>B>D, that is, the rinsing time has the greatest impact on the deodorization effect, followed by the concentration of salt solution, fish meat , The ratio of fish bones to brine is the third, and the last is the rinsing temperature. According to the results of the index mean (k), the optimal combination can be obtained: A2B3C2D1, the concentration of instant salt solution is 6g / 100ml, fish meat, fish bones: brine 1:4 (m / m), rinsing time is 60min, and rinsing temperature is 30°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com