Integrated equipment and method for coprocessing methane and malodorous substances

A technology for co-processing and malodor, applied in chemical instruments and methods, separation methods, and air quality improvement, etc., can solve the problem that methane and malodorous substances cannot be biologically treated at the same time, reduce investment and operating costs, simplify operations, and reduce operating costs. The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

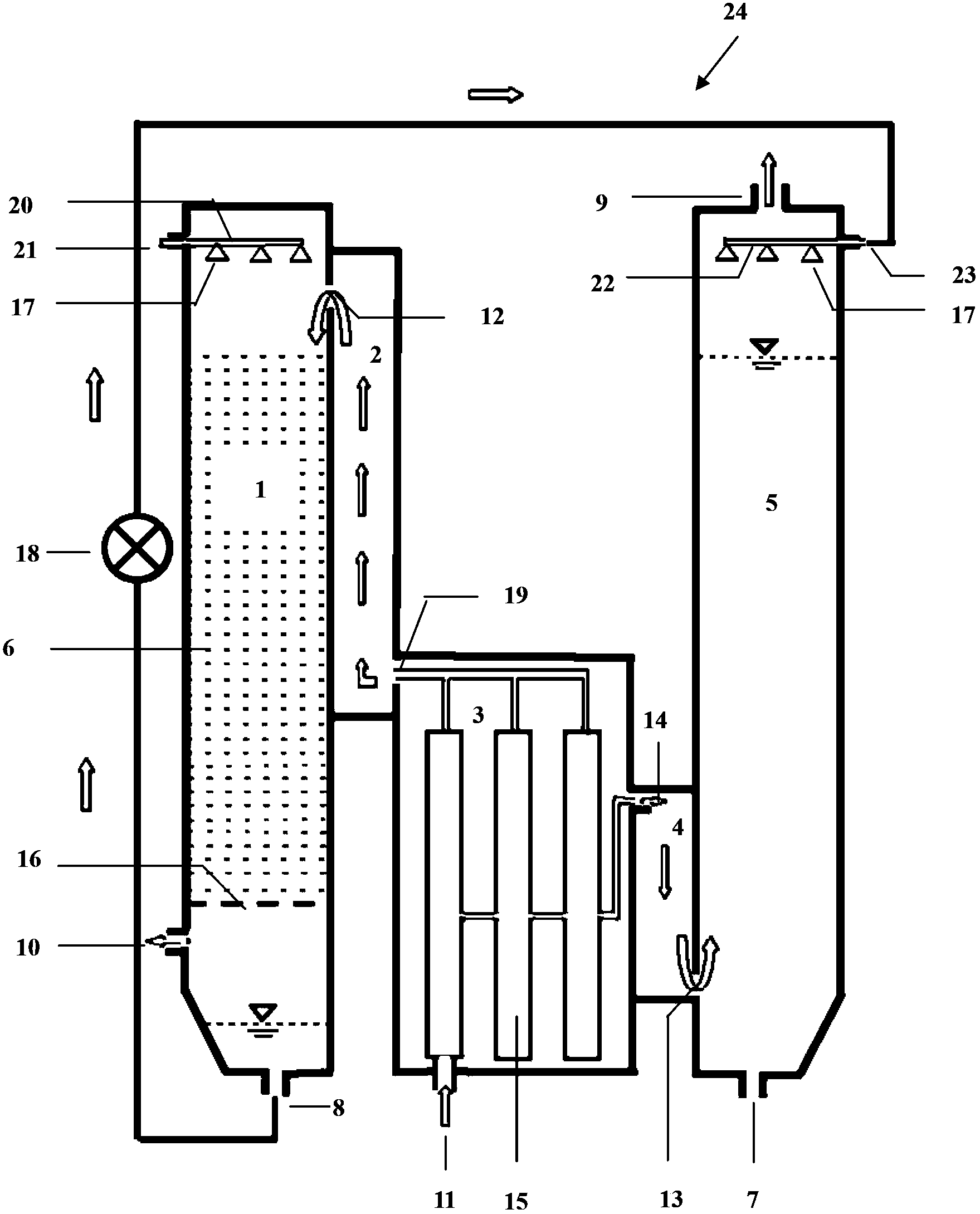

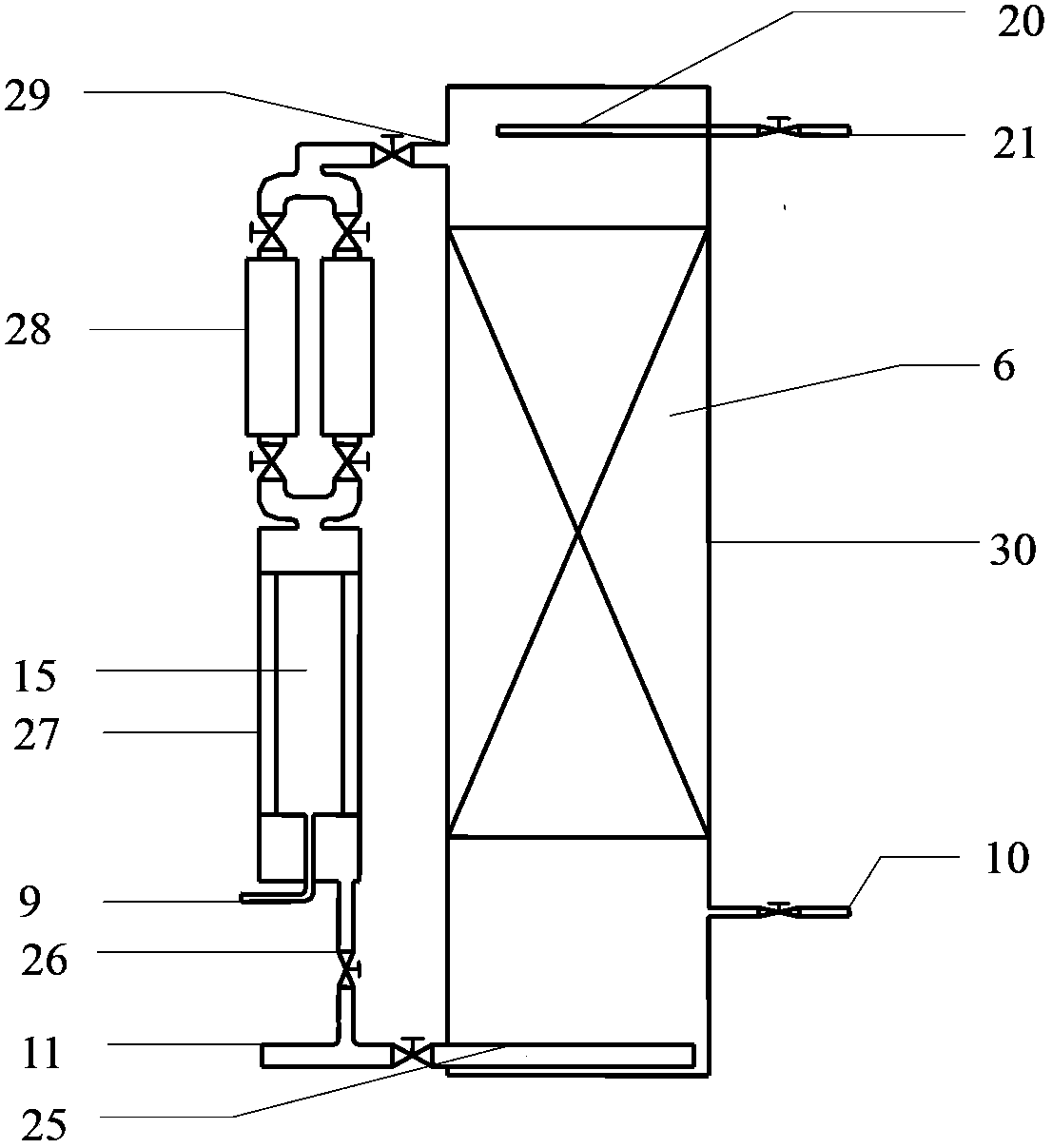

[0049] See figure 1 . The integrated equipment 24 for co-processing methane and malodorous substances made of plastic plates has a length, width, and height of 0.80m, 0.50m, and 1.50m respectively; it includes a gas membrane separation area 3 for accommodating sulfur-oxidizing bacteria, Downflow aerobic zone 1 for fillers attached by ammonia oxidizing bacteria and nitrifying bacteria, upflow anaerobic zone 5 for accommodating suspended aqueous solution containing methane oxidizing bacteria and denitrifying bacteria, permeate gas diversion zone 2 and Retentate gas diversion zone 4.

[0050] The gas membrane separation zone 3 is composed of a first container, the downflow aerobic zone 1 is composed of a second container, and the upflow anaerobic zone 5 is composed of a third container.

[0051] Between the first container and the second container there is a fourth container forming the permeate gas diversion area 2, between the first container and the third container there is ...

Embodiment 2

[0060] See figure 1 . The integrated equipment 24 for synergistic treatment of methane and malodorous substances made of stainless steel plates has a length, width and height of 0.5m, 0.3m and 1.0m respectively. The equipment structure and the waste gas treatment method are the same as in Example 1.

[0061] Under room temperature conditions, waste gas treatment is carried out by using the above-mentioned integrated equipment 24 for co-processing of methane and malodorous substances. A plurality of gas membrane modules 15 are installed in the first container, the gas separation membrane of the gas membrane module is a coiled membrane, a hollow fiber membrane or a flat membrane, and the membrane material is polyimide, polysulfone or polydimethylsiloxane . Sulfur oxidizing bacteria, ammonia oxidizing bacteria and nitrifying bacteria attached to filler 6 are housed in the second container, and filler 6 is that inorganic filler is gravel, ceramsite or gac; Or organic filler is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com