Preparation of red mud-based polymer catalyst and application of catalyst in organic dye degradation

A polymer and red mud-based technology, applied in the direction of physical/chemical process catalysts, water pollutants, chemical instruments and methods, etc., can solve problems such as energy consumption and secondary pollution, and achieve no discharge of three wastes and no secondary pollution , the effect of easing degradation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

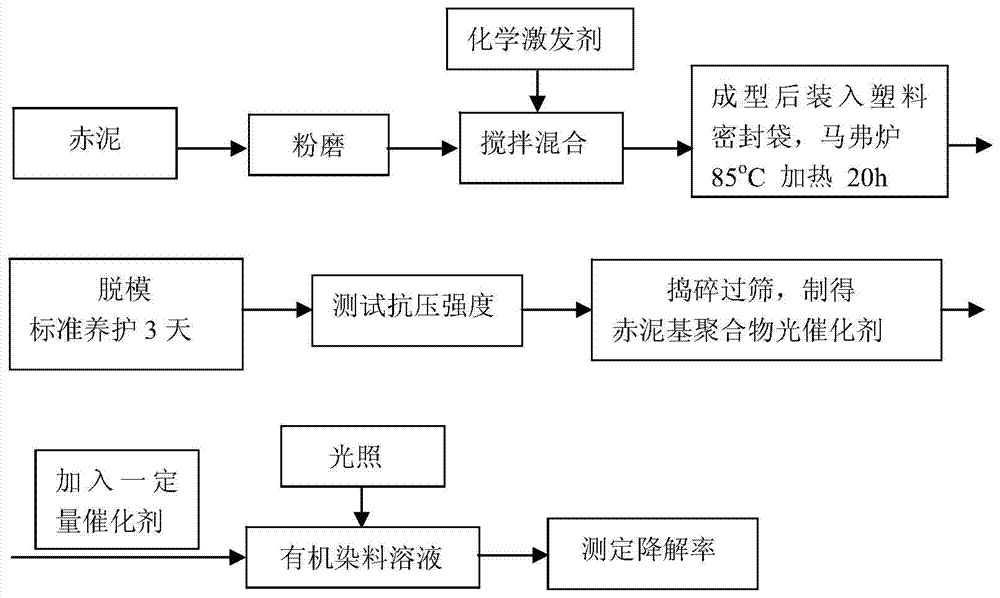

Method used

Image

Examples

Embodiment 1

[0082] Accurately weigh 900 grams of Guangxi Bayer red mud (hereinafter referred to as red mud) as the basis of measurement (100%); adopt the external mixing method, and the amount of sodium silicate is 18% of the weight of red mud; water and red mud The mass ratio was 0.3.

[0083] Sodium silicate is dissolved in water to form an aqueous solution at room temperature. Pour the sodium silicate aqueous solution into a double-rotation and double-speed slurry mixer, then add red mud for high-speed stirring to form a uniform slurry, put the slurry into a 30mm×30mm×40mm iron triple mold, and put it in the glue Vibrate on the sand vibrating table, and scrape it with a scraper to get the formed red mud-based polymer. Put the formed red mud-based polymer (specimen) into a plastic film sealed bag, heat it at 85°C for 20 hours, and then release it from the mold, and then maintain it for 3 days under standard curing conditions. The compressive strength is 10.8MPa.

[0084] Then crush a...

Embodiment 2

[0086] All the operation steps are the same as in Example 1, except that the amount of sodium silicate is 20% of the weight of the red mud, and they are respectively cured for 3 days under standard curing conditions. The compressive strength of the red mud-based polymer is 17MPa as measured by a compression tester.

Embodiment 3

[0088] All the operation steps are the same as in Example 1, except that the dosage of sodium silicate is 23% of the weight of the red mud, and they are respectively cured for 3 days under standard curing conditions, and the compressive strength of the red mud-based polymer is 7.5 MPa measured by an anti-compression instrument .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com