Reflective solar-control low-emissivity coated glass and preparation method thereof

A low-emissivity coating and sunlight control technology, applied in the direction of coating, etc., can solve the problems of increased haze, surface roughness, and haze of coated glass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

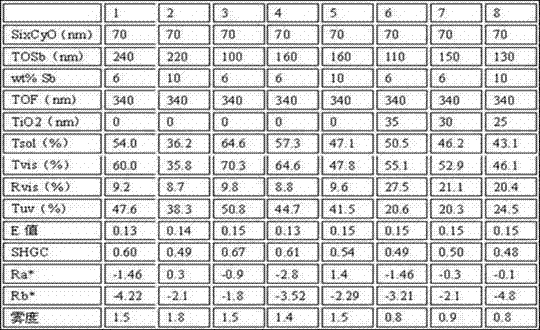

[0013] Now illustrate the present invention with 1-8 embodiment;

[0014] In this example, chemical vapor deposition is used to deposit each film layer. The specific steps are:

[0015] In the first step, a carbon-doped silicon oxide layer is plated as a color suppression layer. Specifically, silane, ethylene, carbon dioxide, and carrier gas nitrogen are formed into a mixed gas according to the volume ratio [1~10%]:[10~40%]:[10~40%]:[10~79%], and the mixed gas It is introduced into the feed chamber of the coater, and sprayed onto the moving hot glass surface below it through the feed slit under the coater, and flows through the glass surface in a laminar flow, and a chemical reaction occurs on the glass surface. deposited into a film. The temperature of the hot glass is 660-700°C, the speed of the glass is 100-500 m / hour, and the refractive index of the film is 1.6-1.8 and the thickness is 50-100nm.

[0016] In the second step, an antimony-doped tin oxide layer is deposited...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com