Post-sprayed micro-ecological preparation for expanded feeds, and preparation method and application of preparation

A technology of micro-ecological preparation and extruded feed, which is applied to the micro-ecological preparation of feed and its application field, can solve the problems of affecting the nutritional value of feed and inactivation of bacteria, and achieves the promotion of aquatic animal growth, low surface tension, and increased nutrition. effect of value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

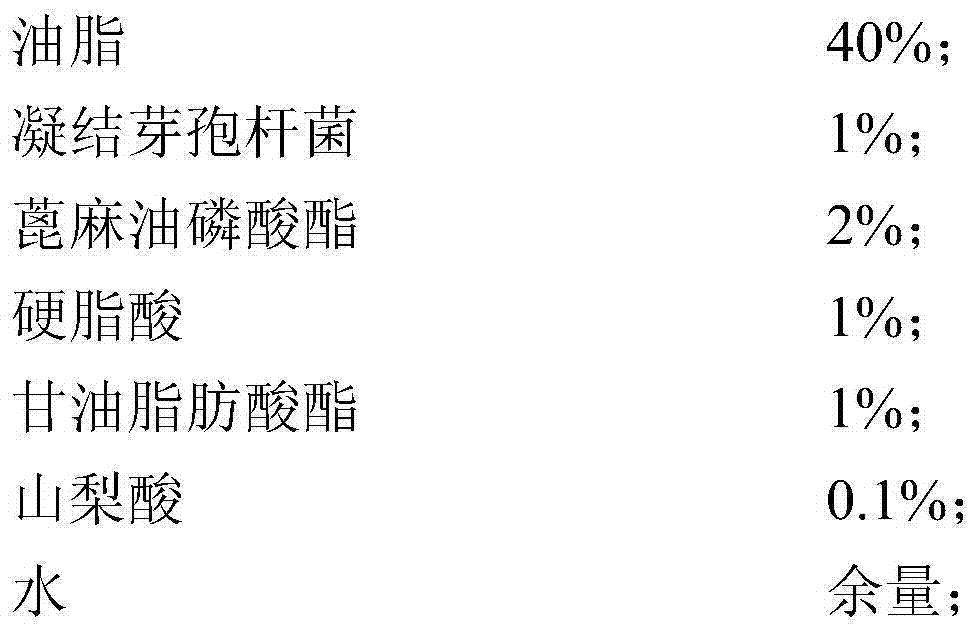

[0027] The following ingredients are calculated by mass percentage:

[0028]

[0029] (1) Take the above components by mass percentage; dissolve Bacillus coagulans (purchased from Sanmenxia Bosio Biotechnology Co., Ltd.) in water, and then add stearic acid and glycerin fatty acid ester (purchased from Jinan East Runjing Chemical Technology Co., Ltd.), sorbic acid, and stir each component evenly under a YRTZ concentric twin-shaft mixer with a rotation speed of 60r / min to obtain a liquid Bacillus coagulans preparation.

[0030] (2) Mix the oil with the emulsifier castor oil phosphate, stir evenly under the YRTZ concentric twin-shaft mixer with a rotation speed of 60r / min, add the liquid Bacillus coagulans preparation prepared in step (1), and the model is The JJ2 / 60 homogenizer is homogenized for 3 minutes, so that all components are fully mixed, and the extruded feed is obtained, and then the live Bacillus coagulans preparation is sprayed.

[0031] (3) After homogenization,...

Embodiment 2

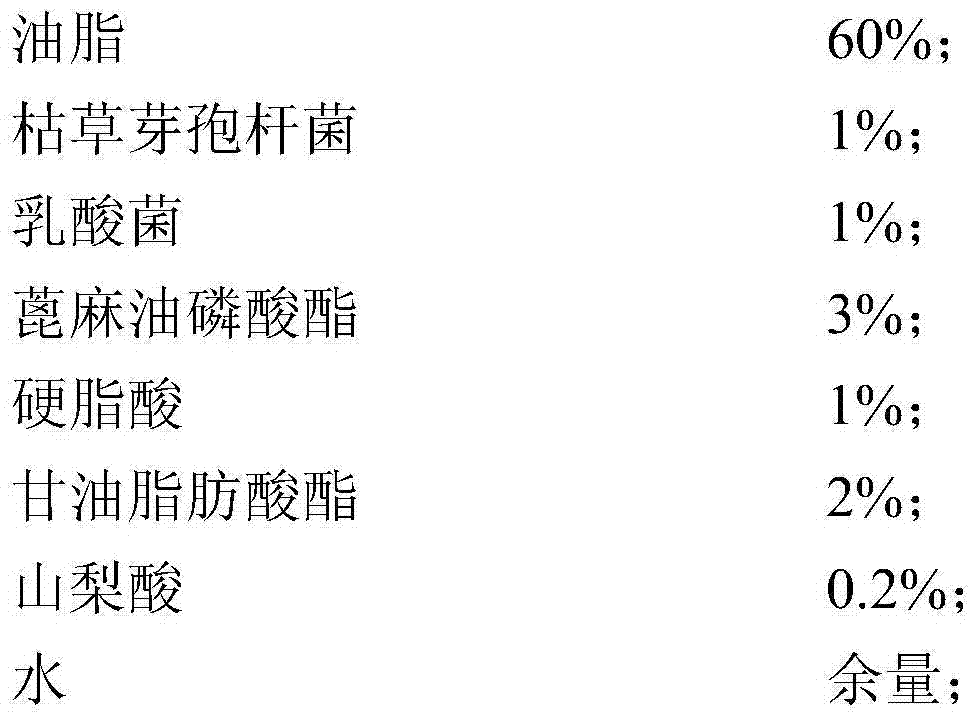

[0033] The following ingredients are calculated by mass percentage:

[0034]

[0035] (1) Take the above components in terms of mass percentage; dissolve Bacillus subtilis (purchased from Sanmenxia Bosio Biotechnology Co., Ltd.) and lactic acid bacteria (purchased from Sanmenxia Boseo Biotechnology Co., Ltd.) in water, and then simultaneously Add stearic acid, glycerin fatty acid ester (purchased from Jinan Dongrun Fine Chemical Technology Co., Ltd.), sorbic acid, and stir each component evenly under a YRTZ concentric twin-shaft mixer at a speed of 60r / min to obtain liquid subtilis Bacillus and Lactobacillus preparations.

[0036] (2) Mix the oil with the emulsifier castor oil phosphate, stir evenly under the YRTZ concentric twin-shaft mixer with a rotation speed of 60r / min, add the liquid Bacillus subtilis and lactic acid bacteria preparation prepared in step (1), and pass through Homogenize with a JJ2 / 60 homogenizer for 5 minutes to fully mix each component, and then spr...

Embodiment 3

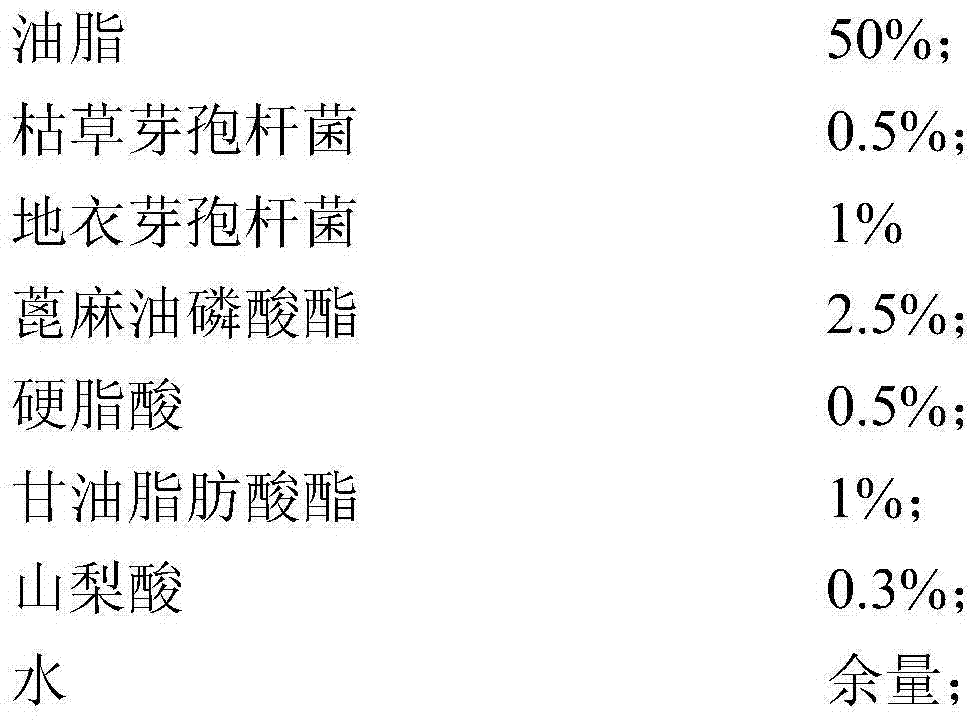

[0039] The following ingredients are calculated by mass percentage:

[0040]

[0041] (1) Take the above components in terms of mass percentage; dissolve Bacillus subtilis (purchased from Sanmenxia Bosio Biotechnology Co., Ltd.) and Bacillus licheniformis (purchased from Sanmenxia Bosio Biotechnology Co., Ltd.) in water, and then Add stearic acid, glycerin fatty acid ester (purchased from Jinan Dongrun Fine Chemical Technology Co., Ltd.), sorbic acid at the same time, and stir each component evenly under the YRTZ concentric twin-shaft mixer at a speed of 60r / min to obtain Liquid Bacillus subtilis and Bacillus licheniformis preparation.

[0042] (2) Mix the oil with the emulsifier castor oil phosphate, stir evenly under the YRTZ concentric twin-shaft mixer with a rotation speed of 60r / min, and add the liquid Bacillus subtilis and Bacillus licheniformis preparations prepared in step (1) , Homogenized by a JJ2 / 60 homogenizer for 5 minutes to fully mix the components to obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com