High-sensitivity hot electron thermal radiation detection meter and producing method thereof

A thermal radiation and detector technology, applied in electrical radiation detectors, circuits, electrical components, etc., can solve the problems of inability to achieve multi-layer structure absorption rate, affecting device response speed, serious device heat leakage, etc. The effect of small external interference and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

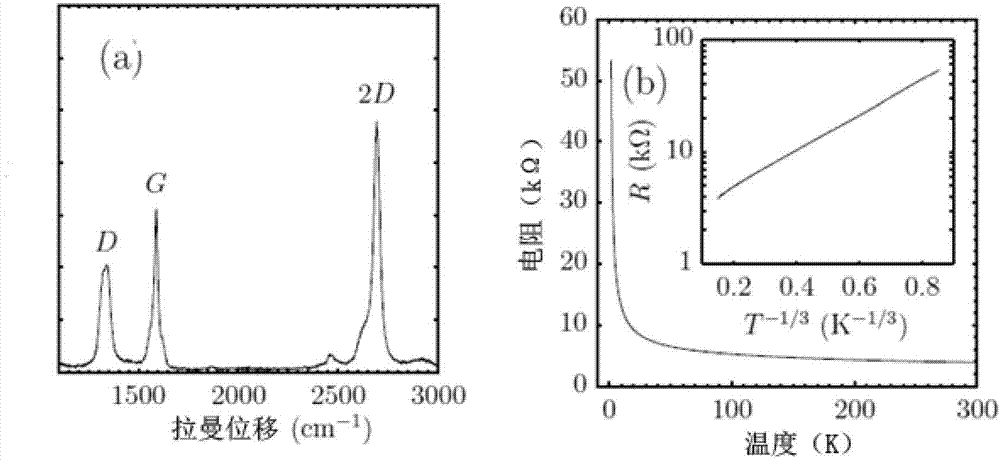

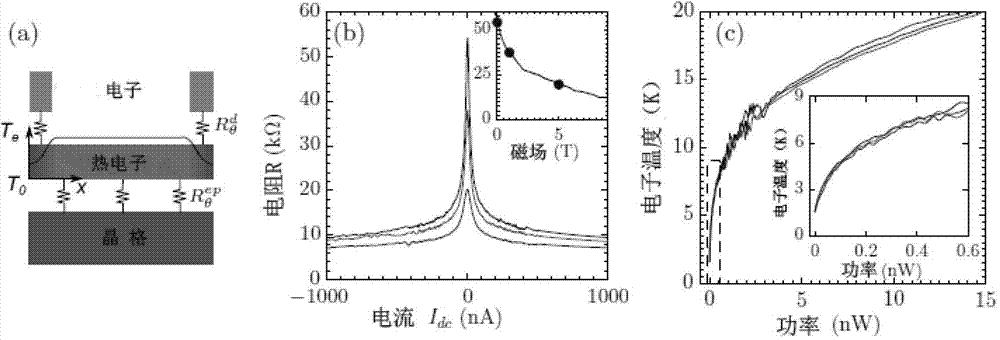

[0042] Embodiment 1, preparation of disordered graphene electronic thermal radiation detector

[0043] 1) Using SiO 2 285nm thick SiO 2 / N-Si substrate, which was purchased from the Institute of Microelectronics, Peking University. SiO with acetone 2 / N-Si substrates were ultrasonically cleaned to remove organic residues, and then they were ultrasonically cleaned with deionized water to remove impurities such as metal ions, and then the samples were quickly dried with a nitrogen gun.

[0044] 2) Throw a layer of PMMA with a molecular weight of 950K, a mass fraction of 6%, and a thickness of about 300nm at a speed of 3000r / min for 45 seconds (the start and stop time is 15 seconds), and bake at 170°C for 4 minutes.

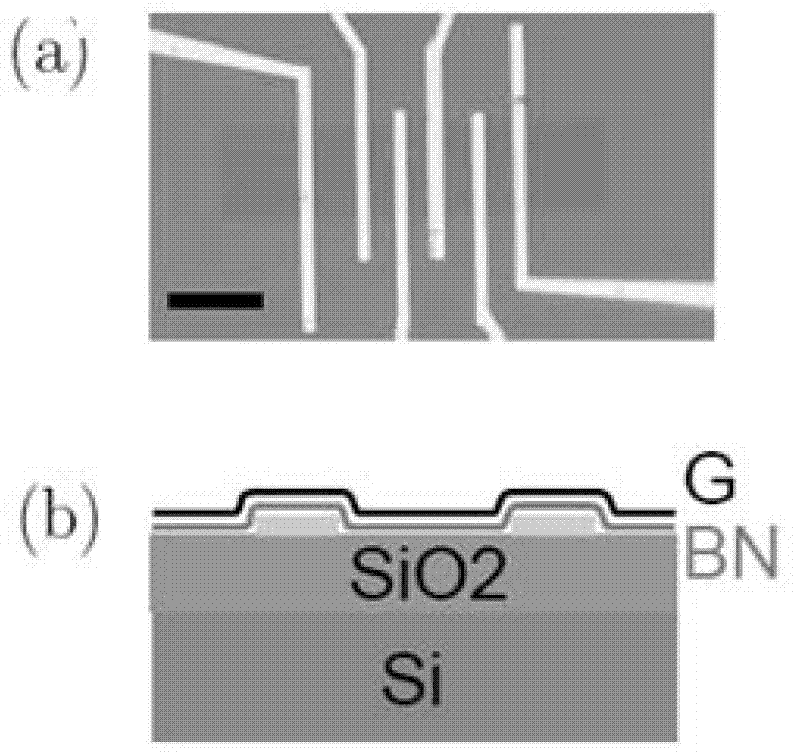

[0045] 2) Electron beam exposure is carried out on the substrate after gluing at the selected position to produce such as figure 1 The six-electrode structure with a spacing of 2.5 μm in (a).

[0046] The electron beam exposure machine used in this experiment i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com