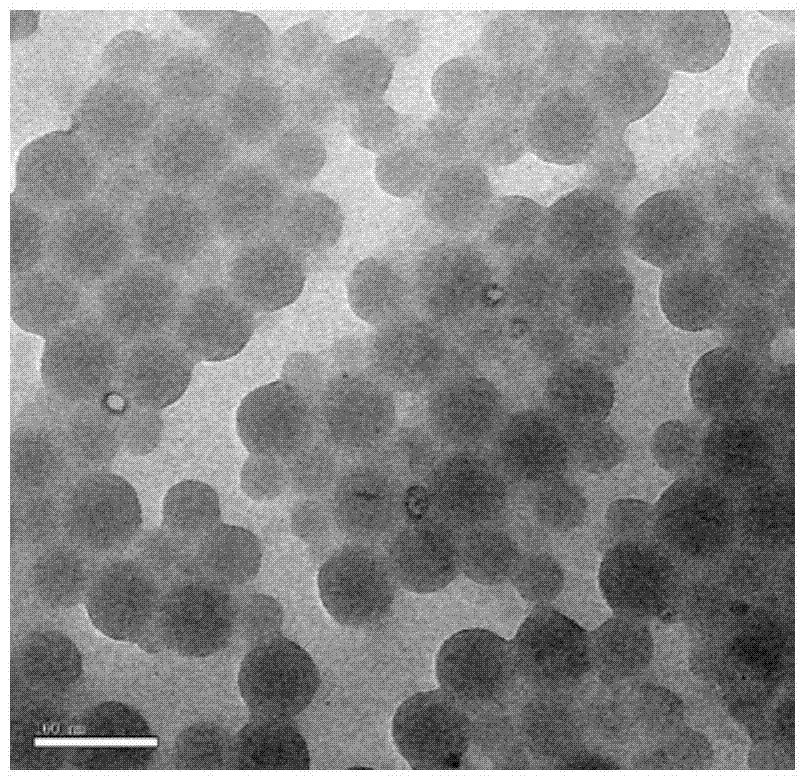

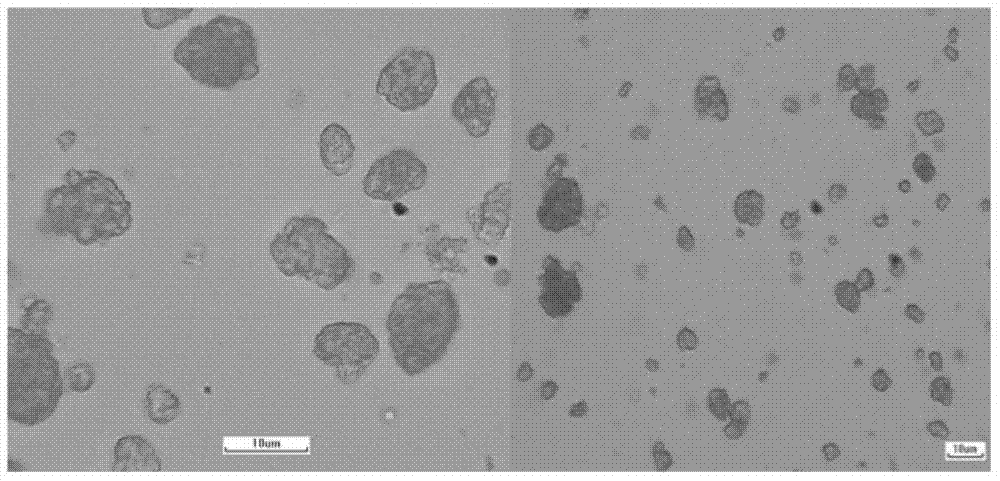

Colorful ink powder prepared by adopting miniemulsion polymerization and method thereof

A technology of fine emulsion polymerization and color toner, which is applied in the direction of instruments, developers, optics, etc., can solve the problems of easy leakage and weak combination, and achieve the effect of simple process, regular particle shape and uniform color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Select the following raw materials in parts by weight: 70 parts of styrene, 20 parts of butyl acrylate, 3 parts of absolute ethanol, 5 parts of paraffin, 5 parts of yellow pigment, 0.05 parts of charge regulator (E84 metal complex), potassium persulfate 1.8 parts, emulsifier 15 parts, coagulant (calcium chloride) 20 parts, hydrophobic nano-SiO 2 : 2 parts, 900 parts of deionized water.

[0043] Dissolve the above-mentioned charge regulator in absolute ethanol, disperse the yellow pigment PY17 in the mixed monomer of styrene and butyl acrylate under ultrasonic, add the ethanol solution of the charge regulator into the mixed monomer under ultrasonic, and continue the ultrasonic dispersion for 10 minutes. Prepare mixed material A;

[0044] Then put the mixture A in a water bath at 65°C, add the paraffin to the mixture A, wait until the paraffin is completely melted, stir to obtain a uniform organic phase B;

[0045] After that, put the emulsifier (combined with sodium la...

Embodiment 2

[0054] Select the following raw materials in parts by weight: 75 parts of styrene, 22 parts of butyl acrylate, 5 parts of absolute ethanol, 10 parts of paraffin, 8 parts of blue pigment, 0.1 part of charge regulator (E84 metal complex), persulfuric acid Potassium 2 parts, emulsifier 20 parts, coagulant (magnesium chloride) 25 parts, hydrophobic nano SiO 2 3 parts, 800 parts of deionized water.

[0055] Dissolve the above charge regulator in absolute ethanol, ultrasonically disperse the blue pigment PB15:3 in the mixed monomer of styrene and butyl acrylate, add the ethanol solution of the charge regulator into the mixed monomer under ultrasound, and continue the ultrasonic dispersion 15min, prepared mixed material A;

[0056] Then put the mixture A in a water bath at 65°C, add the paraffin to the mixture A, wait until the paraffin is completely melted, stir to obtain a uniform organic phase B;

[0057] After that, put the emulsifier (compounded by sodium lauryl sulfate and T...

Embodiment 3

[0063] Select the following raw materials in parts by weight: 80 parts of styrene, 25 parts of butyl acrylate, 8 parts of absolute ethanol, 15 parts of paraffin, 10 parts of red pigment, 0.2 parts of charge regulator (E84 metal complex), potassium persulfate 2.5 parts, emulsifier 25 parts, coagulant (aluminum chloride) 35 parts, hydrophobic nano-SiO 2 5 parts, 700 parts of deionized water.

[0064] Dissolve the above-mentioned charge regulator in absolute ethanol, ultrasonically disperse the red pigment PR122 in the mixed monomer of styrene and butyl acrylate, add the ethanol solution of the charge regulator into the mixed monomer under ultrasonic, continue ultrasonic dispersion for 15 minutes, and prepare Obtain mixed material A;

[0065] Then put the mixture A in a water bath at 65°C, add the paraffin to the mixture A, wait until the paraffin is completely melted, stir to obtain a uniform organic phase B;

[0066] After that, put the emulsifier (combined with sodium laury...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com