Preparation method of multiple composite anode material of lithium ion battery

A technology for lithium ion batteries and negative electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of poor cycle stability, unsuitable for commercial applications, unfavorable buffer silicon volume expansion, etc., to achieve good cycle life, heavy The effect of high availability and lower actual cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

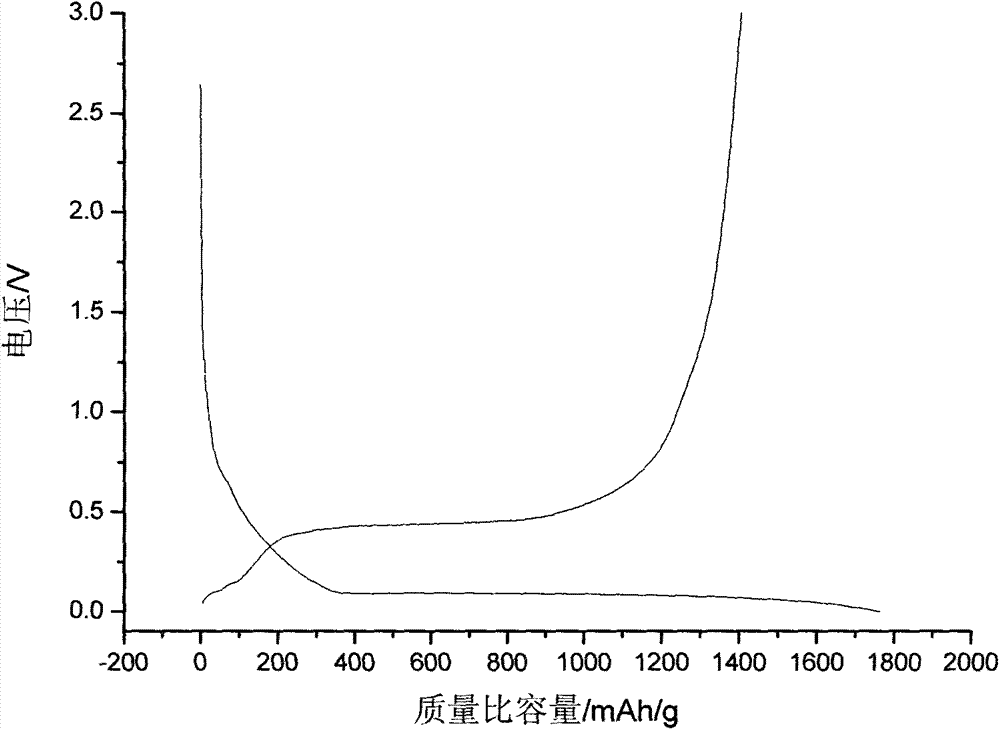

Embodiment 1

[0019] Take 0.3mol of silicon powder, 0.1mol of silicon monoxide and 0.1mol of sucrose for ball milling and mixing, then under the protection of a mixed gas of hydrogen and argon with a volume ratio of 1:20, the temperature is raised to 800°C at a rate of 2°C per minute, Carbonized and sintered at 800°C for 5 hours, cooled naturally to room temperature, and ball milled for 10 minutes to obtain a preliminary sample of silicon / silicon monoxide / carbon multiple composite structure. Disperse 10 g of the sample obtained above into 100 ml of a mixed solution of ethyl orthosilicate and ethanol, wherein the volume ratio of ethyl orthosilicate to ethanol is 1:4, stir and mix for 1 hour, then add excess distilled water dropwise to make orthosilicate All ethyl esters were hydrolyzed to silica, and the resulting samples were dried at 120°C. Then, the obtained sample and polyvinyl chloride were mixed by ball milling at a mass ratio of 3:1, and then heated to 600°C at a rate of 2°C per minut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com