A kind of carbon-coated carbon gadolinium quantum dot and preparation method thereof

A carbon gadolinium quantum and carbon coating technology, which is applied in the field of quantum dot preparation, can solve the problems of difficult purification, low preparation efficiency, complicated outsourcing carbon steps, etc., and achieves the effects of good controllability, uniform size and no environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

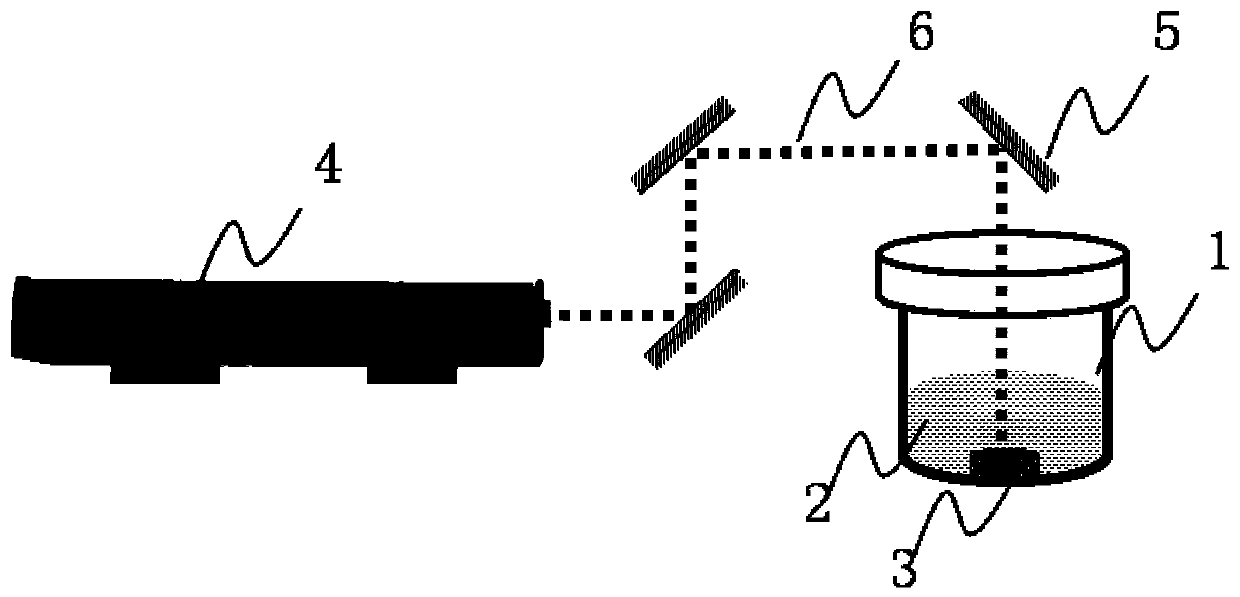

[0046] In this example, carbon-coated carbon gadolinium quantum dots are prepared by using high-purity gadolinium target as the metal gadolinium source and toluene as the carbon source. For the preparation method, see figure 1 ,Specific steps are as follows:

[0047] (1) At room temperature, clean the quartz beaker with ultrasonic waves, and after airtight drying, place a circular high-purity gadolinium target with a mass of 3 grams at the bottom of the quartz beaker, add 50 mL of toluene, and then cover the quartz beaker with a quartz plate , flush the inside of the quartz beaker with high-purity argon gas through a hose for 10 minutes to remove the air in the quartz beaker, and then seal the quartz beaker;

[0048] (2) Select high-energy pulsed laser with ultraviolet light with a laser wavelength of 355nm, single pulse power as 200mJ, and operating frequency as 5Hz, and irradiate the gadolinium target in a focused manner for 60 minutes. The optical path is shown in figure 1...

Embodiment 2

[0054] In this example, carbon-coated carbon gadolinium quantum dots are prepared by using high-purity gadolinium target as the metal gadolinium source and toluene as the carbon source. For the preparation method, see figure 1 ,Specific steps are as follows:

[0055] (1) At room temperature, clean the quartz beaker with ultrasonic waves, and after airtight drying, place a circular high-purity gadolinium target with a mass of 3 grams at the bottom of the quartz beaker, add 50 mL of toluene, and then cover the quartz beaker with a quartz plate , flush the inside of the quartz beaker with high-purity argon gas through a hose for 10 minutes to remove the air in the quartz beaker, and then seal the quartz beaker;

[0056] (2) Choose ultraviolet light with a laser wavelength of 355nm from a high-energy pulsed laser, choose a single pulse power of 400mJ, and a working frequency of 5Hz, and irradiate the gadolinium target in a focused manner for 60 minutes. The optical path is shown i...

Embodiment 3

[0061] In this example, carbon-coated carbon gadolinium quantum dots are prepared by using high-purity gadolinium target as the metal gadolinium source and toluene as the carbon source. For the preparation method, see figure 1 ,Specific steps are as follows:

[0062] (1) At room temperature, clean the quartz beaker with ultrasonic waves, airtightly dry it, place a circular high-purity gadolinium target with a mass of 3 grams at the bottom of the quartz beaker, add 50 mL of toluene, and then cover the quartz beaker with a quartz plate , flush the inside of the quartz beaker with high-purity argon gas through a hose for 10 minutes to remove the air in the quartz beaker, and then seal the quartz beaker;

[0063] (2) Choose green light with a laser wavelength of 532nm from a high-energy pulsed laser, choose a single pulse power of 200mJ, choose a working frequency of 5Hz, and irradiate in a focused manner for 60 minutes. The optical path is shown in figure 1 ; The light gray liqu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com