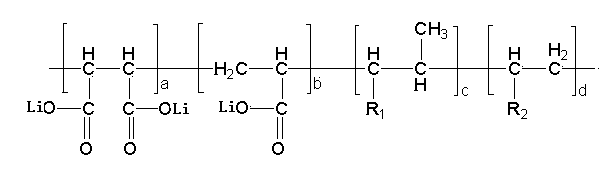

Battery slurry dispersant as well as preparation method and application thereof

A technology of dispersant and slurry, which is applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of difficult control of components, complicated materials, and many steps of dispersant, so as to achieve less usage, increase productivity, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] This embodiment is the preparation process of dispersant, and its preparation process comprises batching, reaction and product pH adjustment:

[0048] (1) Ingredients

[0049] Each raw material and its mass parts are:

[0050] a) Acrylic acid 100 parts

[0051] b) 50 parts of maleic anhydride

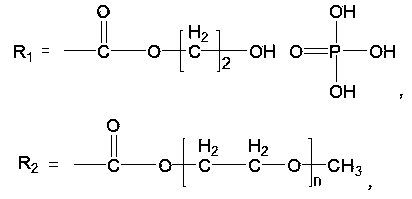

[0052] c) 20 parts of 2-methyl-2-acrylate-2-hydroxyethyl phosphate

[0053] d) Polyoxyethylene allyl ester macromonomer 20 parts

[0054] e) Hydrogen peroxide-lithium sulfite redox initiation system:

[0055] Among them, 0.5 parts of hydrogen peroxide solution with a mass concentration of 18%

[0056] 0.5 parts of lithium sulfite aqueous solution with a mass concentration of 36%

[0057] The above four raw materials of a), b), c) and d) are respectively prepared with deionized water into aqueous solutions with a mass concentration of 60%;

[0058] (2) Reaction

[0059] Using a multi-port reactor connected with a reflux device, each container containing the above-mentioned...

Embodiment 2

[0063] The difference between the preparation process of the present embodiment dispersant and embodiment 1 is:

[0064] 1) Raw materials and mass parts:

[0065]a) Acrylic acid 100 parts

[0066] b) 80 parts of maleic anhydride

[0067] c) 2-methyl-2-acrylate-2-hydroxyethyl phosphate 30 parts

[0068] d) Polyoxyethylene allyl ester macromonomer 30 parts

[0069] e) Hydrogen peroxide-lithium sulfite redox initiation system:

[0070] Among them, 1.5 parts of hydrogen peroxide solution with a mass concentration of 20%

[0071] 1.5 parts of lithium sulfite aqueous solution with a mass concentration of 40%

[0072] 2) The reaction process of dispersant preparation:

[0073] The time for adding the raw materials is 45 minutes, and the temperature in the reactor during the dropping process is between 65°C. After the dropwise addition is completed, the reaction is kept at 65°C for 2.2 hours; after the reaction, adjust the pH of the solution with a 65% lithium hydroxide aqueous ...

Embodiment 3

[0075] The difference between the preparation process of the present embodiment dispersant and embodiment 1 is:

[0076] 1) Raw materials and mass parts:

[0077] a) Acrylic acid 100 parts

[0078] b) Maleic anhydride 100 parts

[0079] c) 40 parts of 2-methyl-2-acrylate-2-hydroxyethyl phosphate

[0080] d) Polyoxyethylene allyl ester macromonomer 40 parts

[0081] e) Hydrogen peroxide-lithium sulfite redox initiation system:

[0082] Among them, 2.0 parts of hydrogen peroxide solution with a mass concentration of 30%

[0083] 2.0 parts of lithium sulfite aqueous solution with a mass concentration of 70%

[0084] 2) The reaction process of dispersant preparation:

[0085] The dripping time of the raw materials is 55min, and the temperature in the reactor during the dropping process is between 70°C. 6.7 Obtain a yellow aqueous lithium-ion battery slurry dispersant solution with a concentration of 30%;

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com