Method for cleaning polluted membrane by using singlet oxygen produced from peroxymonosulfate under induction of inorganic solid peroxide

A peroxide and inorganic solid technology, applied in the field of membrane cleaning, can solve the problems of inconvenient transportation and storage, complicated process operation, short survival time, etc., and achieve the effects of avoiding unclean cleaning, convenient transportation and storage, and stable chemical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

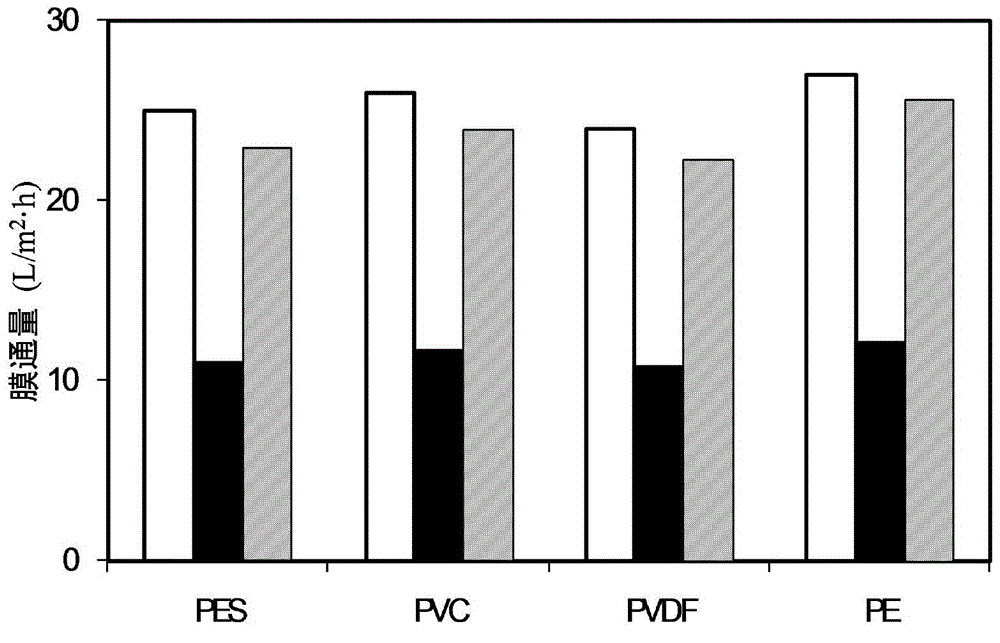

[0016] Specific Embodiment 1: This embodiment is a method for using inorganic solid peroxide to induce persulfate to produce singlet oxygen to clean membrane pollution, which is achieved through the following steps: a. Clean the polluted membrane module Put into the pond that tap water is housed; b, inorganic solid peroxide and peroxymonosulfate are joined in the pond of step 1 according to the ratio of mass ratio being 1:(0.5~5), stir evenly, control peroxomonosulfuric acid The salt concentration is 50-1000 mg / L, soak for 10-180 minutes; c, put the membrane module soaked in step b into another pool filled with tap water for rinsing, that is, the use of inorganic solid peroxide to induce persulfate Generate singlet oxygen to clean membrane fouling.

[0017] The membrane material of the contaminated membrane module described in this embodiment is polyvinylidene fluoride (PVDF), polyethersulfone (PES), polyethylene (PE) or polyvinyl chloride (PVC).

[0018] The inorganic solid ...

specific Embodiment approach 2

[0022] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the inorganic solid peroxide is sodium peroxide (Na 2 o 2 ), calcium peroxide (CaO 2 ), magnesium peroxide (MgO2 ), barium peroxide (BaO 2 ), sodium percarbonate (Na 2 CO 4 ), potassium percarbonate (K 2 CO 4 ) of one or a mixture of several. Other parameters are the same as in the first embodiment.

[0023] In this embodiment, when the inorganic solid peroxide is a mixture of some of them, it is mixed in any ratio.

specific Embodiment approach 3

[0024] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the persulfate is: sodium persulfate (NaHSO 5 ), potassium persulfate (KHSO 5 ), ammonium persulfate (NH 4 HSO 5 ), calcium persulfate (Ca(HSO 5 ) 2 ), magnesium persulfate (Mg(HSO 5 ) 2 ) in one or several mixtures in any ratio. Other parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com