Method for preparation of high purity alpha phase silicon nitride powder from recovered silicon chip cut sawdust

A technology for phase silicon nitride powder and silicon wafer cutting, applied in chemical instruments and methods, nitrogen compounds, inorganic chemistry, etc. Oxygen content is high, and the effect of reducing production cost, high powder sintering activity and high purity is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

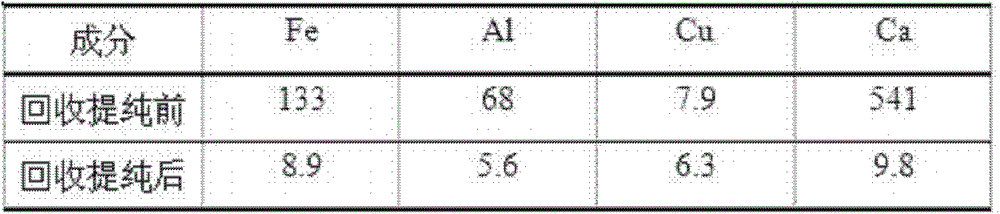

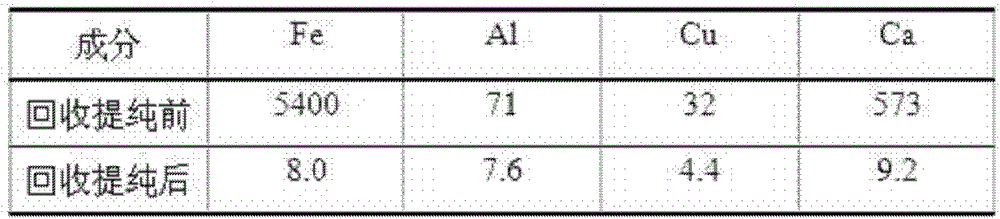

[0027] The silicon wafer diamond wire sawdust was taken, and the silicon wafer wire sawdust powder was recovered and purified as the raw material. The analysis results of the main metal impurities are shown in Table 1.

[0028] Take 100 grams of the raw material powder and loosely pack it in an atmosphere protection furnace; take the method of section heat preservation, the heat preservation temperature is respectively selected as 1000°C, 1300°C and 1350°C, and the heat preservation time is 2 hours, 2 hours and 6 hours respectively; The volume fraction of hydrogen is 5% of the total amount of nitrogen and hydrogen, and the total flow of nitrogen-hydrogen mixed gas is controlled at 200ml / min; the initial volume fraction of argon content is 50% of the total amount of gas, and gradually decreases to zero with the reaction process. Cool down to about 700°C and stop ventilation, then cool down to room temperature with the furnace and leave the furnace.

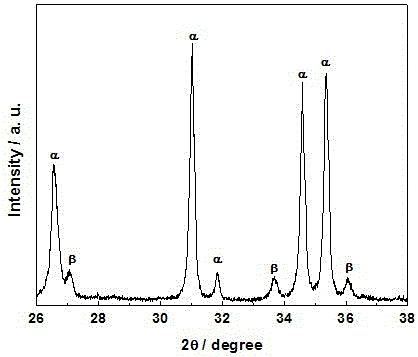

[0029] The synthesized prod...

Embodiment 2

[0033] The silicon wafer diamond wire sawdust was taken, and the silicon wafer wire sawdust powder was recovered and purified as the raw material. The analysis results of the main metal impurities are shown in Table 1.

[0034] Take 160 grams of the raw material powder and loosely pack it in an atmosphere protection furnace; take the method of segmented heat preservation, the heat preservation temperature is respectively selected as 800 ° C, 1200 ° C, 1300 ° C and 1370 ° C, and the heat preservation time is respectively 1 hour, 1 hour, 1 hour and 4 hours; the volume fraction of hydrogen is 15% of the total amount of nitrogen and hydrogen, and the total flow of nitrogen-hydrogen mixed gas is controlled at 150ml / min; the initial volume fraction of argon content is 60% of the total amount of gas, gradually increasing with the reaction process down to zero. Cool down to about 700°C and stop ventilation, then cool down to room temperature with the furnace and leave the furnace.

...

Embodiment 3

[0039] The silicon wafer diamond wire sawdust was taken, and the silicon wafer wire sawdust powder was recovered and purified as the raw material. The analysis results of the main metal impurities are shown in Table 1.

[0040] Take 200 grams of the raw material powder and loosely pack it in an atmosphere protection furnace; take the method of section heat preservation, the heat preservation temperature is respectively selected as 900°C, 1250°C and 1350°C, and the heat preservation time is 2 hours, 2 hours and 8 hours respectively; The volume fraction of hydrogen is 10% of the total amount of nitrogen and hydrogen, and the total flow rate of nitrogen-hydrogen mixed gas is controlled at 100ml / min; the initial volume fraction of argon content is 20% of the total amount of gas, and gradually decreases to zero with the reaction process. Cool down to about 700°C and stop ventilation, then cool down to room temperature with the furnace and leave the furnace.

[0041] The synthesized...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com