Disposal system of municipal dewatering sludge

A disposal system and technology for dewatering sludge, applied in the fields of dewatering/drying/concentrating sludge treatment, sludge treatment, water/sludge/sewage treatment, etc. It can improve the efficiency of sludge drying, ensure the efficiency of anaerobic digestion, and reduce the difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

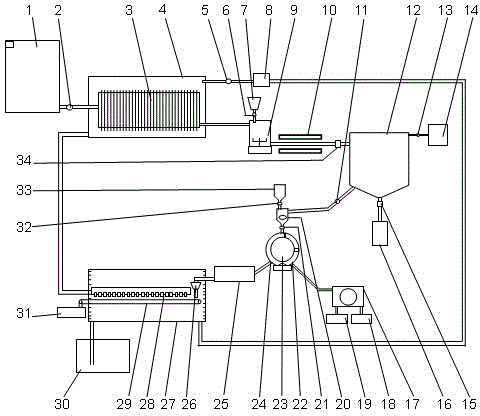

[0011] The present invention will be described in further detail below in conjunction with the accompanying drawings. see Attachment

[0012] A municipal dewatered sludge treatment and disposal system, consisting of a high temperature and high pressure reactor 1, a sludge cooling device, a magnetic powder hopper 7, an agitator 9, a magnetization device 10, an anaerobic digestion chamber 12, a magnetic powder separation device 17, a slurry feeding hopper 20, The metal magnetic separation device 23, the dehydration device 25, the waste heat drying device and the mud cake collection device 31 are composed, the sludge cooling device is composed of the radiator 3 and the first sealing cover 4, and the radiator 3 is arranged in the first sealing cover 4, The radiator 3 is a silo with uniformly distributed cooling fins, and the waste heat drying device is composed of a mud cake forming device 26, a second sealing cover 27, a mud cake conveyor belt 29, an air blowing device 28 and a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com