Internal plasticizing monomer-modified acrylate/inorganic nano composite emulsion and preparation method thereof

A technology of acrylate and inorganic nanometers, applied in the direction of coating, etc., can solve the problems of reducing the effect of product promotion, insufficient gloss, dull color, etc., and achieve the effect of broadening the application range, excellent comprehensive performance, and improving gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

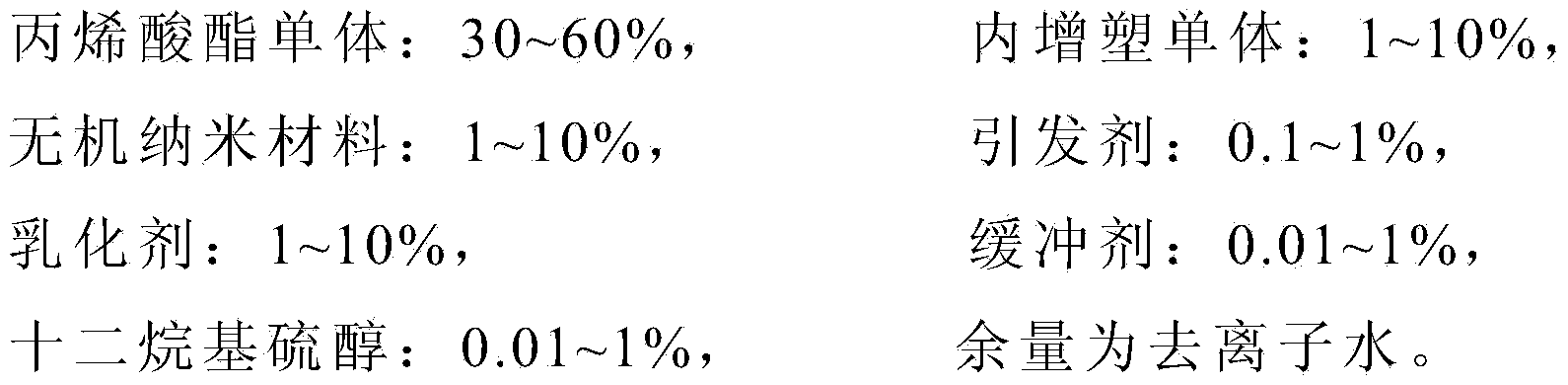

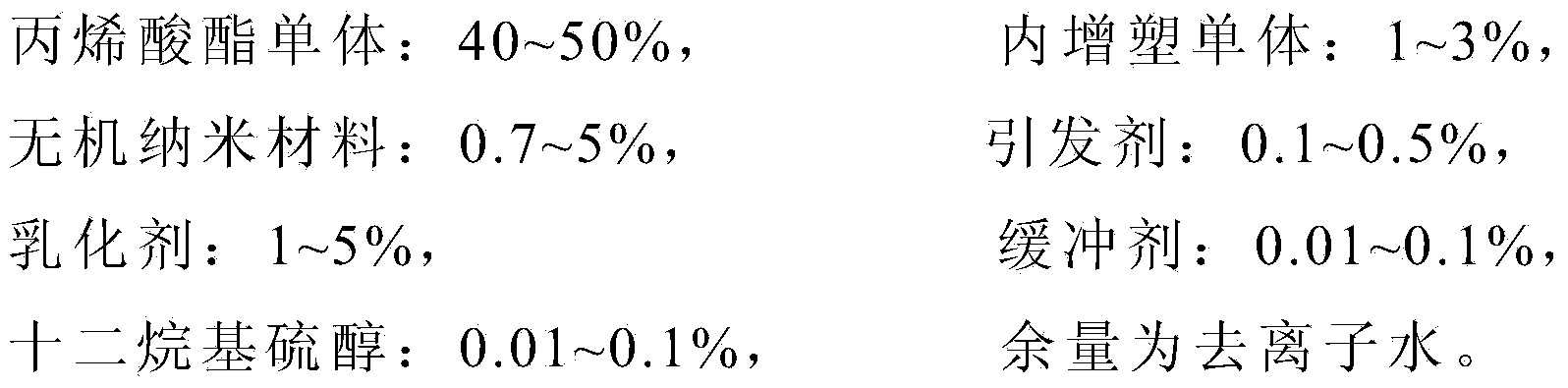

Method used

Image

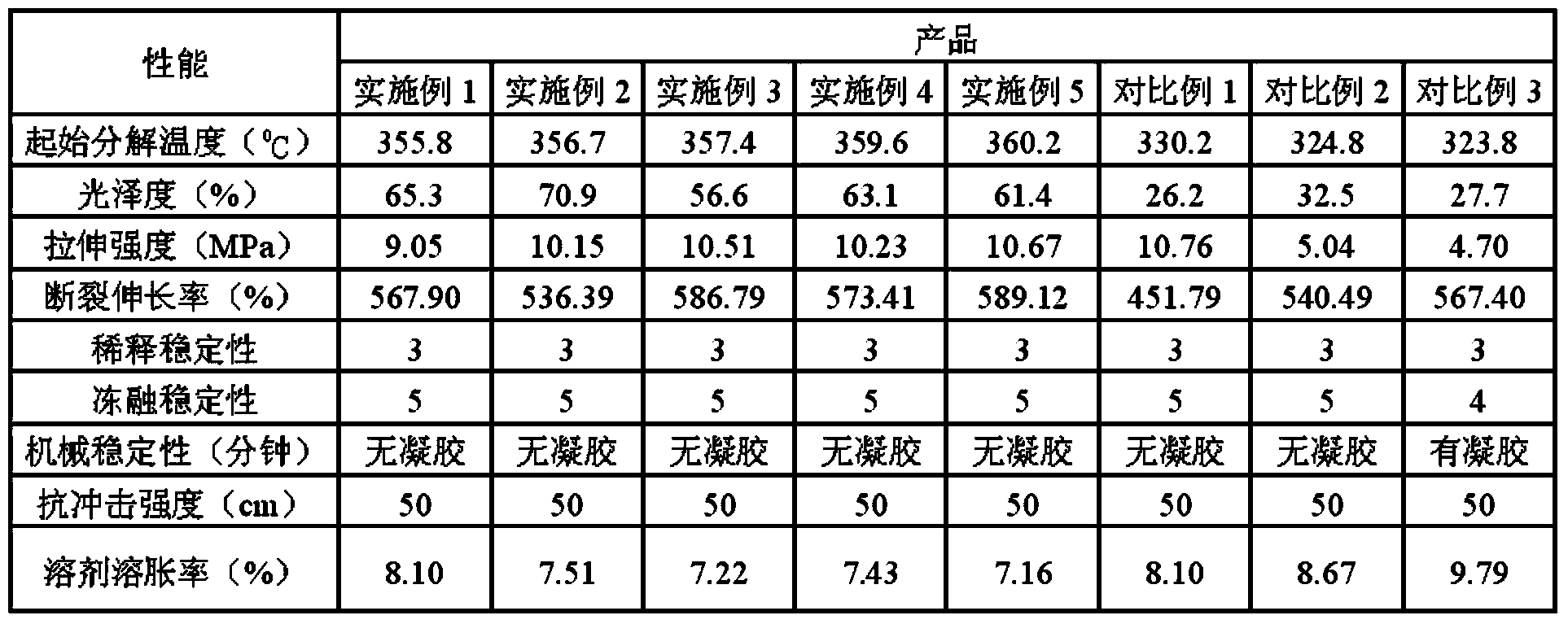

Examples

Embodiment 1

[0032] ①Add 46.8g deionized water, 3.5g sodium lauryl sulfate, 0.06g dodecyl mercaptan, 145g acrylate main monomer and 5.3g maleic acid to the reactor with agitator and condenser Acetate dibutyl ester, stirring and mixing at room temperature to prepare a pre-emulsion;

[0033] ②Dissolve 0.6g of potassium persulfate and 0.09g of sodium bicarbonate into 46.8g of deionized water, stir and mix evenly at room temperature, and prepare the trigger solution;

[0034] 3. Add 2.4g nano-calcium carbonate and 62.4g deionized water to the reactor with agitator, condenser and constant flow pump feeding device, raise the temperature to 78, and add the total weight of the initiator solution prepared by step 2 in the reactor 30% of 30%, wait until the temperature rises to 78 again, and add 3% of the total weight of the pre-emulsion prepared in step 1 to the reactor in ℃;

[0035] ④ After 3-10 minutes, blue light will be generated in the reactor, and the reaction temperature will be controlled...

Embodiment 2

[0038] ①Add 48.3g deionized water, 3.5g sodium dodecylbenzenesulfonate, 0.06g dodecyl mercaptan, 145g acrylate main monomer and 5.3g Monobutyl maleate, stirred and mixed evenly at room temperature, prepared into a pre-emulsion;

[0039] ②Dissolve 0.6g of ammonium persulfate and 0.09g of ammonium bicarbonate into 48.3g of deionized water, stir and mix evenly at room temperature, and prepare the trigger solution;

[0040] ③Add 7.2g of nano-montmorillonite and 64.4g of deionized water to the reactor with agitator, condenser, and constant-flow pump feeding device, raise the temperature to 78, and add the initiator solution prepared in step ② to the reactor at ℃ 35% of the weight, wait until the temperature rises to 78 again, and add 8% of the total weight of the pre-emulsion prepared in step 1. to the reactor in ℃;

[0041]④ After 3-10 minutes, blue light will be generated in the reactor, and the reaction temperature will be controlled at 78-80°C, and the initiator solution prepa...

Embodiment 3

[0044] ①Add 49.8g deionized water, 3.5g alkylphenol polyoxyethylene ether, 0.06g dodecyl mercaptan, 145g acrylate main monomer and 5.3g rich Dibutyl maleate, stirred and mixed evenly at room temperature, prepared into a pre-emulsion;

[0045] 2. Dissolve 0.6g potassium thiosulfate and 0.09g ammoniacal liquor into 49.8g deionized water, stir and mix evenly at room temperature, and prepare the trigger solution;

[0046] ③ Add 12.08g of nano-alumina and 66.4g of deionized water to the reactor with agitator, condenser, and constant-flow pump feeding device, raise the temperature to 78, and add the total weight of the initiator solution prepared in step ② to the reactor 40% of the 40%, wait until the temperature rises to 78 again, 12% of the total weight of the pre-emulsion liquid prepared in step 1. is added to the reactor in ℃;

[0047] ④ After 3 to 10 minutes, blue light is generated in the reactor, and the reaction temperature is controlled at 78 to 80°C. The initiator solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com