Preparation method of konjac glucomannan fiber scaffold material

A technology of konjac glucomannan and fiber scaffold, which is applied in the field of biomedical materials, can solve the problems of insufficient mechanical properties and poor degradation of KGM, and achieve the effects of good gelation, good cartilage defects, and controllable degradation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

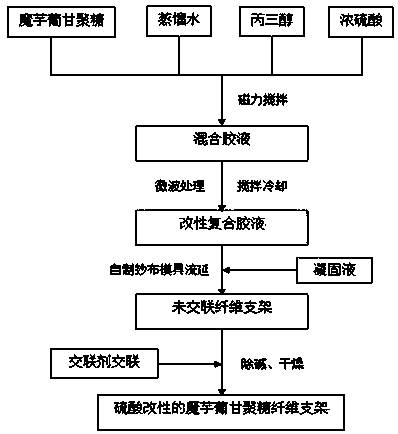

[0028] Such as figure 1 As shown, the preparation method of the konjac glucomannan fiber scaffold material described in this embodiment specifically includes the following steps:

[0029] (1) Dilute concentrated sulfuric acid with distilled water, then add glycerin, and stir evenly to obtain a mixed solution A, wherein the volume ratio of concentrated sulfuric acid to water is 1:200, and the volume ratio of glycerol to water is 1:100;

[0030] (2) Add konjac glucomannan to the mixed solution A, and stir to dissolve it completely to obtain the mixed glue B. The mass ratio of konjac glucomannan to the water added in step (1) is 1:70;

[0031] (3) Microwave the mixed glue B for 10 minutes, stir it at room temperature to cool it, filter it through 400 mesh, and then place it under a negative pressure of 500 mmHg for defoaming to obtain a modified composite glue C, which is sealed for later use ;

[0032] (4) Add glycerol to absolute ethanol, and stir evenly to obtain a mixture D...

Embodiment 2

[0037] Such as figure 1 As shown, the preparation method of the konjac glucomannan fiber scaffold material described in this embodiment specifically includes the following steps:

[0038] (1) Dilute concentrated sulfuric acid with distilled water, then add glycerin, and stir evenly to obtain a mixed solution A, wherein the volume ratio of concentrated sulfuric acid to water is 1:1000, and the volume ratio of glycerol to water is 1:500;

[0039] (2) Add konjac glucomannan to mixed solution A, and stir to completely dissolve to obtain mixed glue B. The mass ratio of konjac glucomannan to water added in step (1) is 1:90;

[0040] (3) Microwave the mixed glue B for 5 minutes, stir it at room temperature to cool it, filter it through 400 mesh, and then place it under a negative pressure of 450 mm Hg to degas to obtain the modified composite glue C, seal it for later use ;

[0041] (4) Add glycerol to absolute ethanol, and stir evenly to obtain a mixture D, wherein the volume ratio ...

Embodiment 3

[0046] Such as figure 1 As shown, the preparation method of the konjac glucomannan fiber scaffold material described in this embodiment specifically includes the following steps:

[0047] (1) Dilute concentrated sulfuric acid with distilled water, then add glycerin, and stir evenly to obtain a mixed solution A, wherein the volume ratio of concentrated sulfuric acid to water is 1:2000, and the volume ratio of glycerol to water is 1:1000;

[0048] (2) Add konjac glucomannan to the mixed solution A, and stir to dissolve it completely to obtain the mixed glue B. The mass ratio of konjac glucomannan to the water added in step (1) is 1:120;

[0049] (3) Microwave the mixed glue B for 1 min, stir it at room temperature to cool it, filter it through 200 mesh, and then place it under a negative pressure of 400 mmHg for defoaming to obtain a modified composite glue C, seal it for later use ;

[0050] (4) Add glycerol to absolute ethanol, and stir evenly to obtain a mixture D, wherein ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com