Method for simultaneously separating wogonin and baicalein monomers from scutellaria baicalensis

A technology for simultaneous separation of wogonin and wogonin is applied in the field of simultaneous separation of wogonin and baicalein monomer, which can solve the problems of increased difficulty, low content, limited acid hydrolysis transfer rate, etc. The effect of good clinical application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for simultaneously separating wogonin and baicalein monomer from scutellaria includes the following steps:

[0029] (1) Crush 500g of Scutellaria baicalensis Georgi, add distilled water 6 times the weight of the medicinal material and 5g β-D-glucuronidase (edible enzyme), control the temperature at 50℃, and enzymatically hydrolyze for 3 hours;

[0030] (2) Filter the distilled water, put the scutellaria baicalensis material into the supercritical extraction kettle, set the extraction pressure to 20Mpa, temperature to 50°C, extraction time to 3.5 hours, entrainer ethanol, and 200ml dosage after preheating;

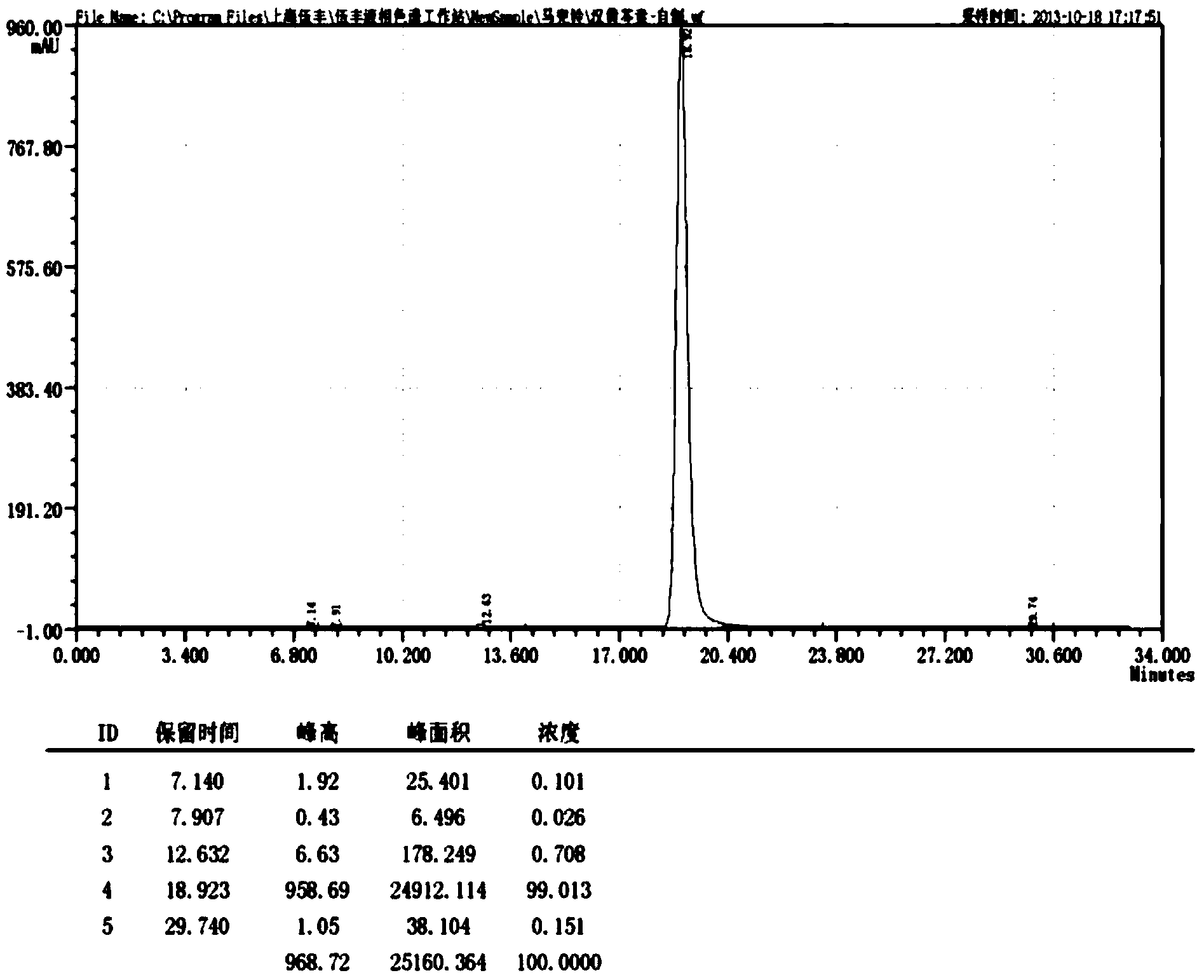

[0031] (3) Collected in sections, concentrated the ethanol solution and recrystallized with ethyl acetate to obtain 25.18g of baicalein and 13.64g of wogonin. The purity of baicalein was 98.23% and the purity of wogonin was 98.35 by HPLC. %.

[0032] Identification and content determination of wogonin and baicalein obtained above:

[0033] 1. Detection method

[0034]...

Embodiment 2

[0055] A method for simultaneously separating wogonin and baicalein monomer from scutellaria includes the following steps:

[0056] (1) Crush 500g of Scutellaria baicalensis Georgi, add distilled water 3 times the weight of the medicinal material and 0.05g snail enzyme (edible enzyme), control the temperature at 60℃, and enzymolyse for 10 hours;

[0057] (2) The distilled water was filtered, and the Scutellaria baicalensis was placed in a supercritical extraction kettle. After preheating, the extraction pressure was set to 35Mpa, the temperature was 40°C, the extraction time was 5 hours, the entrainer was acetone, and the amount was 25ml;

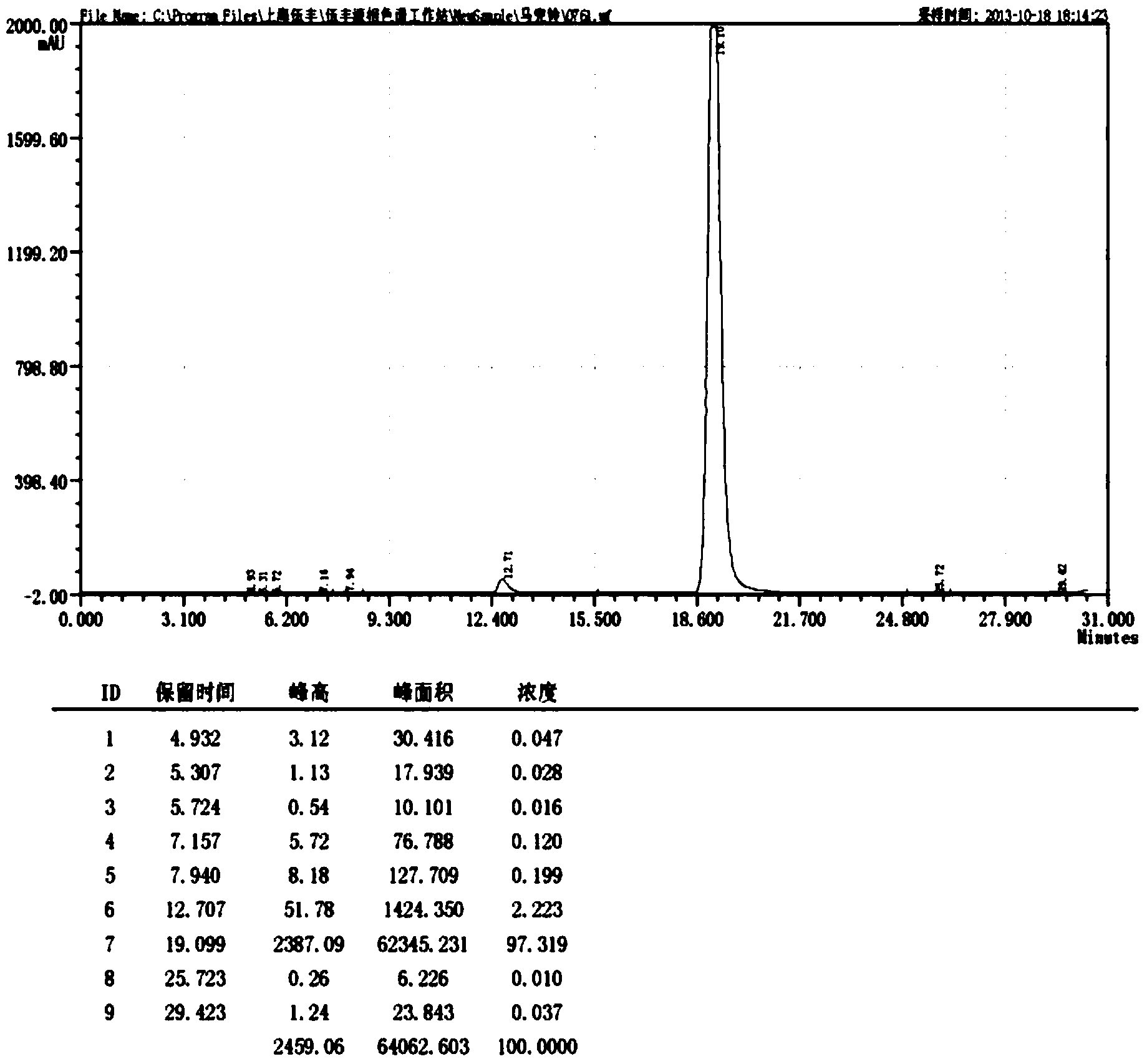

[0058] (3) Collected in sections, concentrated the acetone solution and recrystallized with petroleum ether to obtain 10g baicalein and 1.5g wogonin, respectively. The purity of baicalein was 98.27% and the purity of wogonin was 98.65% by HPLC.

Embodiment 3

[0060] A method for simultaneously separating wogonin and baicalein monomer from scutellaria includes the following steps:

[0061] (1) Crush 500g of Scutellaria baicalensis Georgi, add distilled water 15 times the weight of the medicinal material and 50g cellulase (edible enzyme), control the temperature at 35℃, and enzymatically hydrolyze for 1 hour;

[0062] (2) The distilled water was filtered, and the Scutellaria baicalensis material was placed in a supercritical extraction kettle. After preheating, the extraction pressure was set to 10Mpa, the temperature was 60°C, the extraction time was 1 hour, the entrainer was ethyl acetate, and the amount was 500ml;

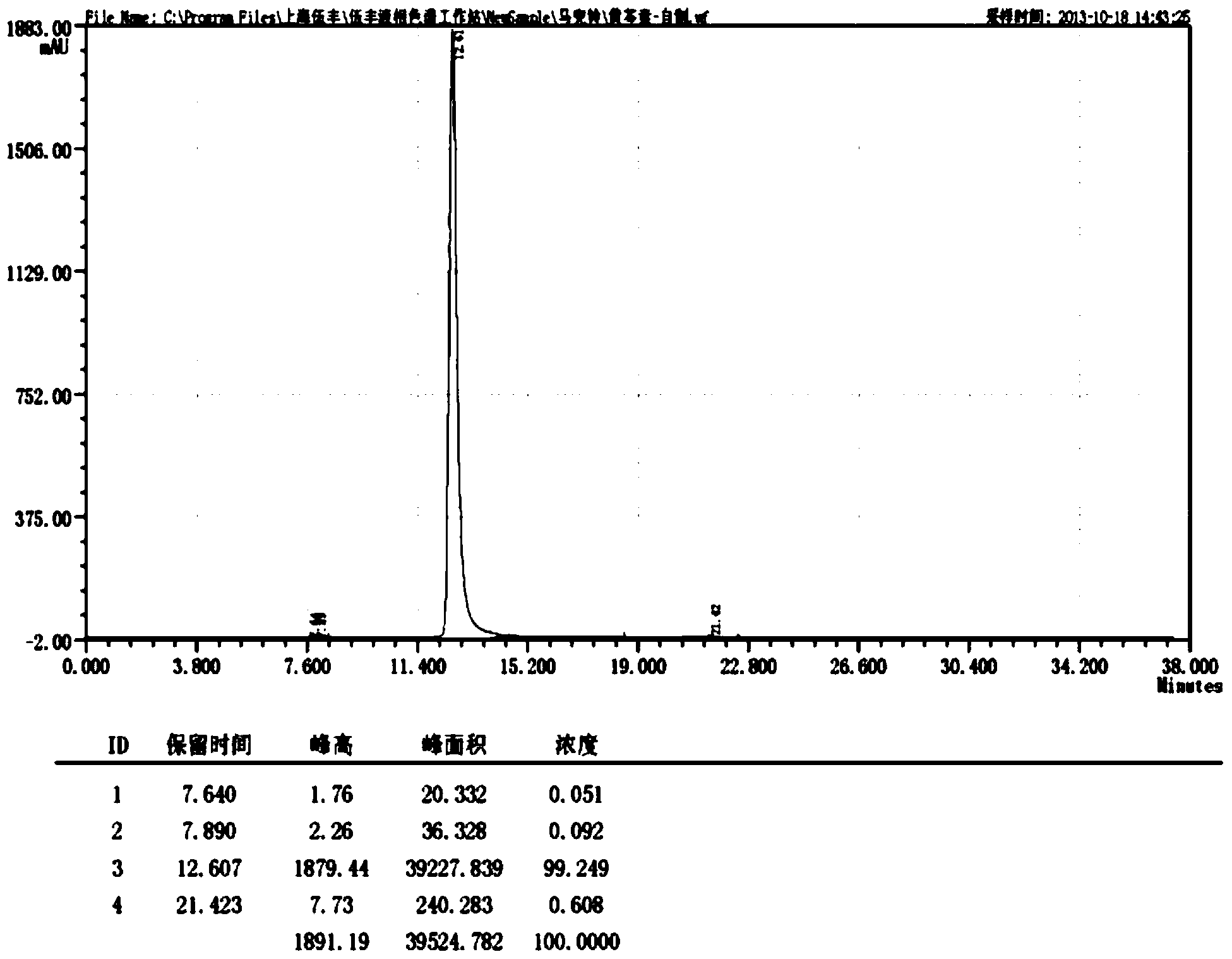

[0063] (3) Collected in sections, concentrated ethyl acetate and recrystallized with acetone to obtain 10.5g of baicalein and 1.3g of wogonin, respectively. The purity of baicalein was 98.45% and the purity of wogonin was 98.29% by HPLC. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com