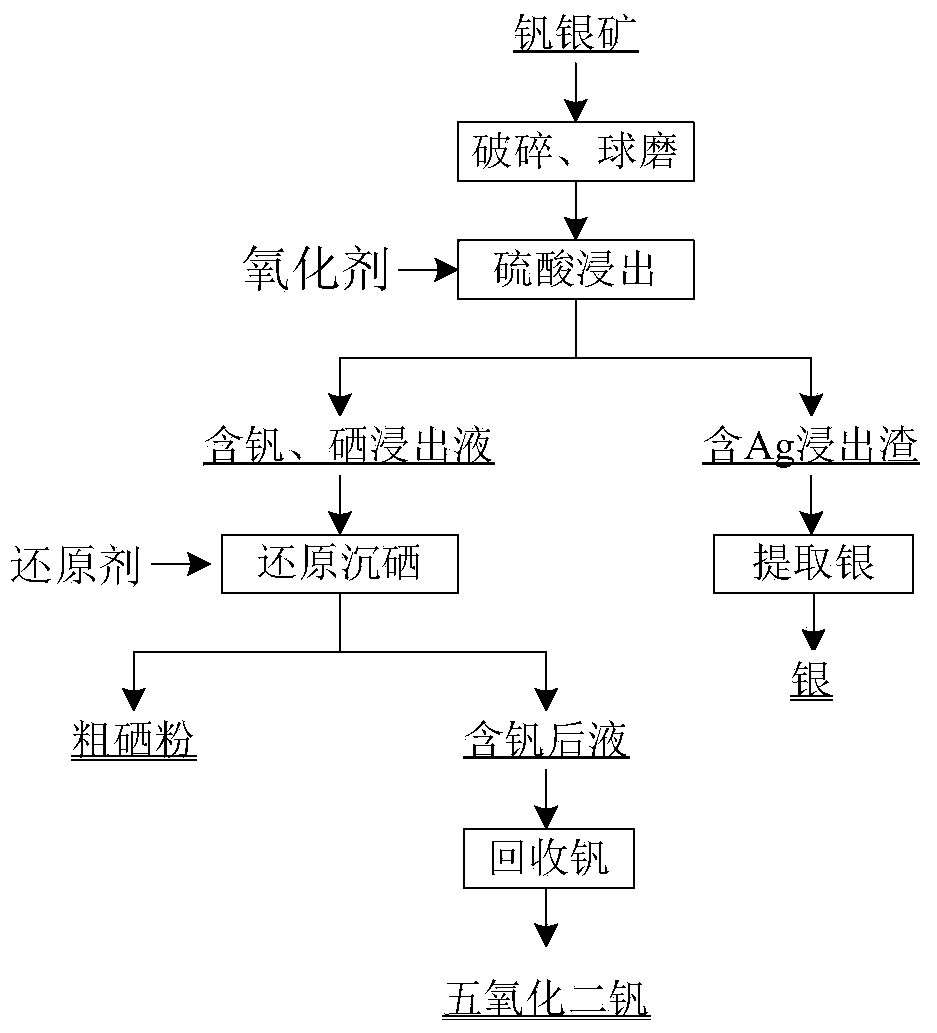

Method for comprehensively recovering selenium, vanadium and silver from vanadium silver polymetallic ore containing selenium employing wet process

A technology for recovering selenium from polymetallic ore is applied in the field of non-ferrous metal metallurgy, which can solve the problems of high energy consumption, flying dust and low selenium recovery rate, and achieve the effects of high metal recovery rate, low production cost and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The vanadium-silver ore containing selenium is crushed and ball-milled until the particle size is less than 0.074mm, accounting for 90%. 2mol / l sulfuric acid solution is mixed with the vanadium-silver ore at a liquid-solid ratio of 2:1, and sodium chlorate with a mass of 3% of the vanadium-silver ore is added. After reacting at a temperature of 90°C for 8 hours, solid-liquid separation was carried out. At this time, the vanadium leaching rate was 85%, and the selenium leaching rate was 85%. Reduction and selenium precipitation are carried out on the leaching solution, and sulfur dioxide gas is introduced into the amount of 3Kg / Kg-selenium to obtain selenium powder and vanadium-containing liquid, and the vanadium-containing liquid is subjected to reduction and neutralization, extraction and stripping, and vanadium precipitation according to the traditional process Calcination to prepare vanadium pentoxide products. The silver-containing leaching slag is traditionally cya...

Embodiment 2

[0035] The vanadium-silver ore containing selenium is crushed and ball-milled until the particle size is less than 0.074mm, accounting for 90%, 3mol / l sulfuric acid solution is mixed with the vanadium-silver ore at a liquid-solid ratio of 3:1, and chlorine gas with a mass of 6% of the mass of the vanadium-silver ore is added. After reacting at a temperature of 90°C for 10 hours, solid-liquid separation was carried out. At this time, the leaching rate of vanadium was 88%, and the leaching rate of selenium was 86%. Reduction and selenium precipitation are carried out on the leaching solution, and sulfur dioxide gas is introduced at a rate of 4Kg / Kg-selenium to obtain selenium powder and vanadium-containing liquid, and the vanadium-containing liquid is subjected to reduction and neutralization, extraction and stripping, and vanadium precipitation according to the traditional process Calcination to prepare vanadium pentoxide products. The silver-containing leaching slag is traditi...

Embodiment 3

[0037] Selenium-containing vanadium-silver ore is crushed and ball-milled to a particle size of 0.074 mm or less, accounting for 95%, 2mol / l sulfuric acid solution is mixed with vanadium-silver ore at a liquid-solid ratio of 5:1, and hydrogen peroxide with 8% vanadium-silver ore quality is added. After reacting at a temperature of 80°C for 24 hours, solid-liquid separation was carried out. At this time, the leaching rate of vanadium was 85%, and the leaching rate of selenium was 81%. The leaching solution is reduced and selenium-precipitated, and the amount of iron powder added is 6Kg / Kg-selenium to obtain selenium powder and vanadium-containing liquid, and the vanadium-containing liquid is reduced and neutralized, extracted and stripped, and vanadium-precipitated and calcined to prepare pentoxide Vanadium products. The silver-containing leaching slag is traditionally leached with thiourea and replaced with zinc powder to produce silver products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com