Ground heating floor made of polymer alloy materials and preparation method thereof

A polymer alloy and polymer-based technology, which is applied in the field of polymer alloy floor heating and its preparation, can solve the problems of non-fireproof and flame-retardant properties, energy consumption, and human health hazards of the geothermal floor, and achieve good floor heating conductivity, Simple process, no effect of formaldehyde release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

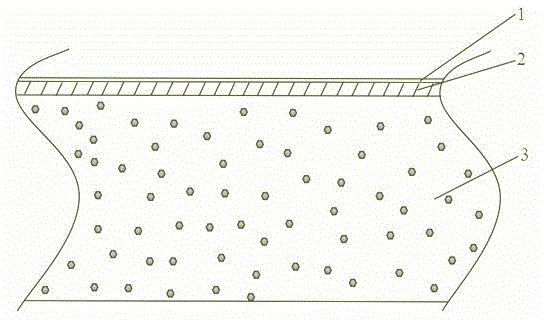

[0040] A floor heating floor made of polymer alloy material, which is a three-layer composite structure, specifically, the bottom layer, that is, the base material layer 1, is a PVC-based polymer alloy composite material layer, and the middle layer 2 is a co-extruded composite decorative layer, and its surface is embossed. ;The base material layer 1 and the middle layer 2 are formed into an overall structure by co-extrusion process, and the uppermost layer is a UV-treated transparent antibacterial and wear-resistant layer 3;

[0041] Wherein, primer layer 1 comprises the component of following weight fraction:

[0042] PVC resin 100 parts

[0043] ABS resin (747S) 30 parts

[0044] Active fine calcium carbonate (1250 mesh) 80 parts

[0045] Calcium zinc composite stabilizer 5.0 parts

[0046] Flame retardant 7 parts

[0047] Processing aid ACR401 2 parts

[0048] 8 copies of CPE

[0049] Semi-refined paraffin wax 0.6 parts

[0050] 0.5 parts of stear...

Embodiment 2

[0060] A floor heating floor made of polymer alloy material, which is a three-layer composite structure, specifically, the bottom layer, that is, the base material layer 1, is a PVC-based polymer alloy composite material layer, and the middle layer 2 is a co-extruded composite decorative layer, and its surface is embossed. ;The base material layer 1 and the middle layer 2 are formed into an overall structure by co-extrusion process, and the uppermost layer is a UV-treated transparent antibacterial and wear-resistant layer 3;

[0061] Wherein, primer layer 1 comprises the component of following weight fraction:

[0062] PVC resin 100 parts

[0063] Glutarimide copolymer 20 parts

[0064] Active fine calcium carbonate (1250 mesh) 100 parts

[0065] Calcium zinc composite stabilizer 5.0 parts

[0066] Flame retardant 7 parts

[0067] Processing aid ACR401 2 parts

[0068] 12 copies of MBS

[0069] Semi-refined paraffin wax 0.6 parts

[0070] 0.5 parts o...

Embodiment 3

[0080] A floor heating floor made of polymer alloy material, which is a three-layer composite structure, specifically, the bottom layer, that is, the base material layer 1, is a PVC-based polymer alloy composite material layer, and the middle layer 2 is a co-extruded composite decorative layer, and its surface is embossed. ;The base material layer 1 and the middle layer 2 are formed into an overall structure by co-extrusion process, and the uppermost layer is a UV-treated transparent antibacterial and wear-resistant layer 3;

[0081] Wherein, primer layer 1 comprises the component of following weight fraction:

[0082] PVC resin 100 parts

[0083] Heat-resistant α-methylstyrene-acrylonitrile copolymer 15 parts

[0084] Active fine calcium carbonate (1250 mesh) 100 parts

[0085] Calcium zinc composite stabilizer 5.0 parts

[0086] Flame retardant 7 parts

[0087] Processing aid ACR401 2 parts

[0088] 9 copies of MBS

[0089] Semi-refined paraff...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com