Molten slag rapid cooling, granulation and waste heat recovery power generation system and method

A melting slag and waste heat recovery technology, applied in furnaces, waste heat treatment, furnace components, etc., can solve problems such as air pollution, melting slag is not effectively used, waste of resources, etc., to improve quality, achieve recycling and utilization, and improve efficiency. and quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

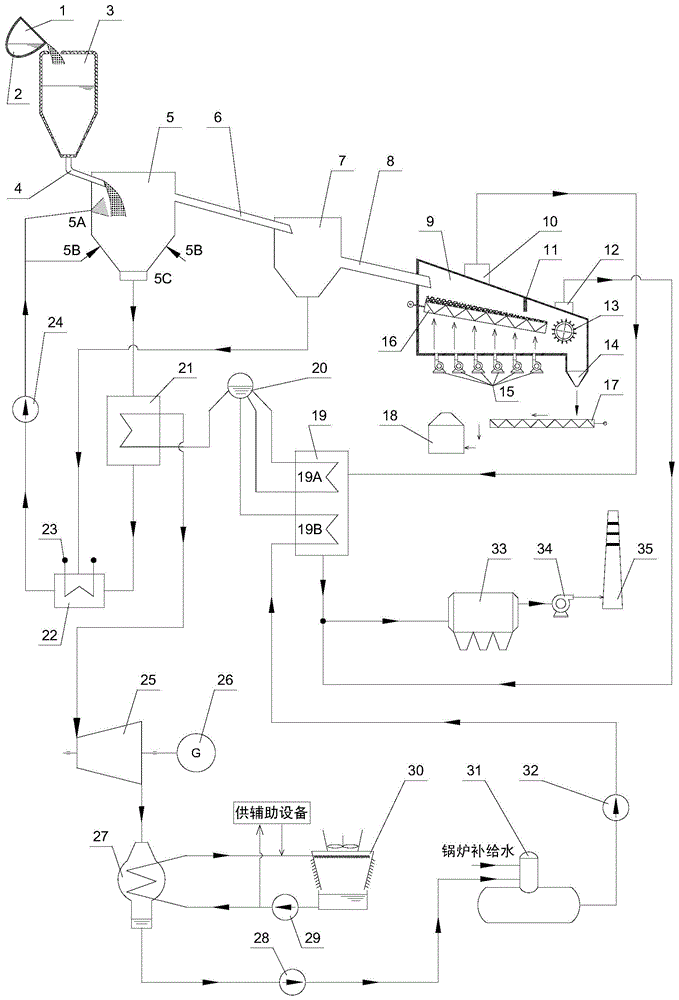

[0024] Such as figure 1 As shown, the molten slag rapid cooling granulation and waste heat recovery power generation system of the present invention includes a slag receiving device, a heat carrier slag rapid cooling granulation device, a slag slow cooling device, a waste heat recovery power generation device and a waste gas purification treatment device.

[0025] The slag receiving device is composed of a slag receiving tank 1 and a slag storage tank 3. The slag receiving tank 1 with external insulation holds the by-product high-temperature molten slag discharged after blast furnace ironmaking, and gathers it to the slag storage which also has external insulation. Tank 3, to overcome the discontinuity of blast furnace slag tapping.

[0026] The heat carrier slag quenching granulation device mainly includes a heat carrier storage tank 23, a h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com