Doping type solar cell front silver paste

A technology for solar cells and silver paste, which is applied to conductive materials, circuits, and electrical components dispersed in non-conductive inorganic materials. It can solve problems such as insufficient bonding and reduce sheet resistance, bonding performance and electrode The electrical properties are uniform and the bonding strength is enhanced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

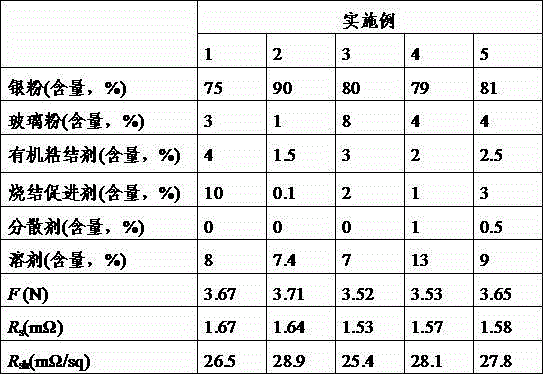

[0021] The present invention is a doped solar cell front silver paste. The components and weight percentages of the paste in Examples 1-5 are shown in Table 1.

[0022] Table 1:

[0023]

[0024] In embodiment 1~5, the tap density of silver powder is 4.5-5.5g / cm 3 , the average particle size is 1~3μm. The glass powder is a glass system of lanthanum, boron, and zinc, with an average particle size of 1-3 μm. The sintering accelerator is compound A(Zn(CH 3 (CH 2 ) 16 COO) 2 ), where A contains the element indium In.

[0025] In embodiment 1, the composition of glass powder and percentage by weight thereof are: La 2 o 3 0.5%, B 2 o 3 85%, Al 2 o 3 2%, ZnO2%, Na 2 O1%, LiO 2 3%, V 2 o 5 6% and P 2 o 5 0.5%. Compound A(Zn(CH 3 (CH 2 ) 16 COO) 2 ), A is elemental indium In, the compound A (Zn(CH 3 (CH 2 ) 16 COO) 2 ) is obtained by the following method: take zinc stearate Zn(CH 3 (CH 2 ) 16 COO) 2 Dissolve the raw materials in a solvent, add raw mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com