Preparation method for boron-doped graphene-modified gel polymer electrolyte

A technology of graphene modification and gel polymer, which is applied in hybrid capacitor electrolytes, hybrid/electric double layer capacitor manufacturing, circuits, etc., can solve the problem of no obvious contribution to ion transport mechanism, little increase in ion conductivity, and reduced pathways To achieve the effect of promoting ion transport, improving interfacial interaction and reducing interfacial impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

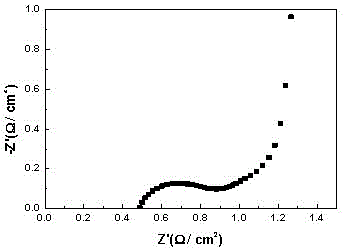

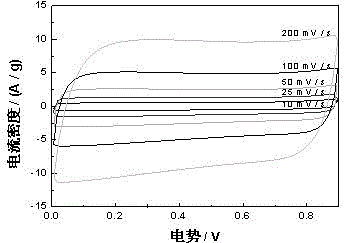

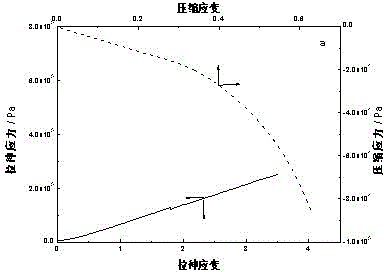

Embodiment 1

[0029] Measure 5 mL of 0.1 g / mL polyvinyl alcohol solution, pour it into a plastic Petri dish (Ф90mm), and let it stand without bubbles. The culture dish containing the solution was placed in a freezer at -20°C for freezing, then thawed at room temperature, and the freezing-thawing cycle operation was repeated 5 times. Take out the gel in the petri dish and soak it in 1mg / mL boric acid solution (pH~11) for about 48h. Take out the soaked gel and soak it in 6mol / L KOH solution. The electrode uses activated carbon (the specific surface area is about 1800 cm 2 / g), the mass ratio of the slurry is mixed according to activated carbon: acetylene black: polytetrafluoroethylene = 82:10:8, pressed into a film on foamed nickel, and dried in a vacuum oven at a constant temperature of 80°C More than 24 hours. The current collector is made of stainless steel compact, and the current collector / carbon electrode / gel polymer electrolyte / collector / spring sheet are assembled into a button ba...

Embodiment 2

[0031] Accurately weigh about 2.5 mg graphite oxide, dissolve it in a mixed solution of 2.5 mL deionized water and 0.05 mL 25% ammonia water, and ultrasonicate for 20 min. Measure 5 mL of 0.1 g / mL polyvinyl alcohol solution, add dropwise to the above graphene oxide aqueous solution under the action of magnetic stirring, mix until the appearance is uniform, continue to shake the solution at room temperature for 24 hours, and the pH of the solution is 9.7-9.8 . Pour the solution into a plastic petri dish (Ф90mm), and let it stand without bubbles. Place the petri dish containing the solution in a freezer at -20°C for freezing, then thaw it at room temperature, and repeat the freeze-thaw cycle operation for 5 Second-rate. Take out the gel in the petri dish and soak it in 1mg / mL boric acid solution (pH~11) for about 48h. Take out the soaked gel and soak it in 6mol / L KOH solution. The electrode uses activated carbon (the specific surface area is about 1800 cm 2 / g), the mass r...

Embodiment 3

[0033] Accurately weigh about 100 mg graphite oxide, dissolve it in a mixed solution of 2.5 mL deionized water and 0.05 mL 25% ammonia water, and ultrasonicate for 20 min. Measure 5 mL of 0.1 g / mL polyvinyl alcohol solution, add dropwise to the above graphene oxide aqueous solution under the action of magnetic stirring, mix until the appearance is uniform, continue to shake the solution at room temperature for 24 hours, and the pH of the solution is 9.7-9.8 . Pour it into a plastic petri dish (Ф90mm), and let it stand without bubbles. Place the petri dish containing the solution in a freezer at -20°C for freezing, then thaw it at room temperature, and repeat the freeze-thaw cycle operation 5 times. Take out the gel in the petri dish and soak it in 1mg / mL boric acid solution (pH~11) for about 48h. Take out the soaked gel and soak it in 6mol / L KOH solution. The electrode uses activated carbon (the specific surface area is about 1800 cm 2 / g), the mass ratio of the slurry is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com