Titanium dioxide waste acid recycling and processing system

A technology of titanium dioxide waste acid and treatment system, which is applied in the steam generation method using heat carrier, ferric sulfate, feed water heater, etc., can solve the problems of insufficient reaction and reduce reaction efficiency, etc. The effect of large and small fluctuation of liquid level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

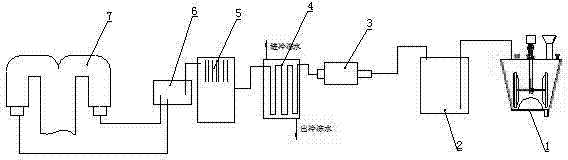

[0019] see figure 1 , the present invention discloses a recovery and utilization treatment system of titanium dioxide waste acid, the innovation point of which is that it mainly includes a reactor 1, a cleaning buffer tank 2, a gas booster 3, a gas cooler 4, and a mist eliminator 5 arranged in sequence , storage distribution tank 6 and hydrogen-fired steam boiler 7.

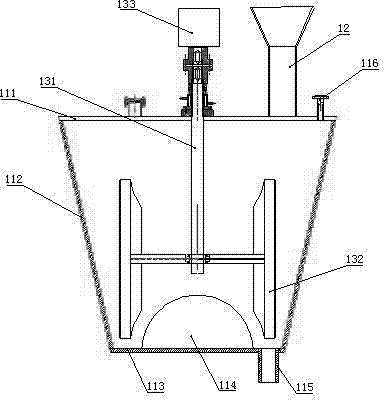

[0020] Such as figure 2 As shown, the reactor mainly includes a reactor shell, a stirring device, and an iron powder feeding device. The reactor shell is an inverted conical frustum formed by setting a top plate 111 and a bottom plate 113 at the upper and lower ends of an inverted conical cylinder 112; the top plate 111 is provided with a liquid feeding pipe 116, an iron powder feeding device 12 and an air outlet pipe. The center of the base plate 113 is provided with a hemispherical material guide protrusion 114, and the non-material guide protrusion area of the base plate 113 has a discharge port 115. Stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com