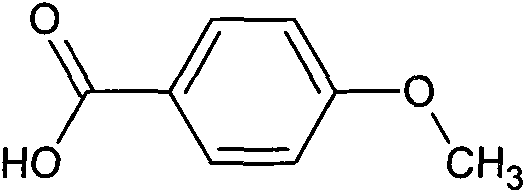

Method for preparing anise acid with anise camphor

A technology of anisole and anisic acid, which is applied in the field of preparing anisic acid by using anisole, can solve the problems of excessive heavy metal content in organic solvent residues, application restrictions, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

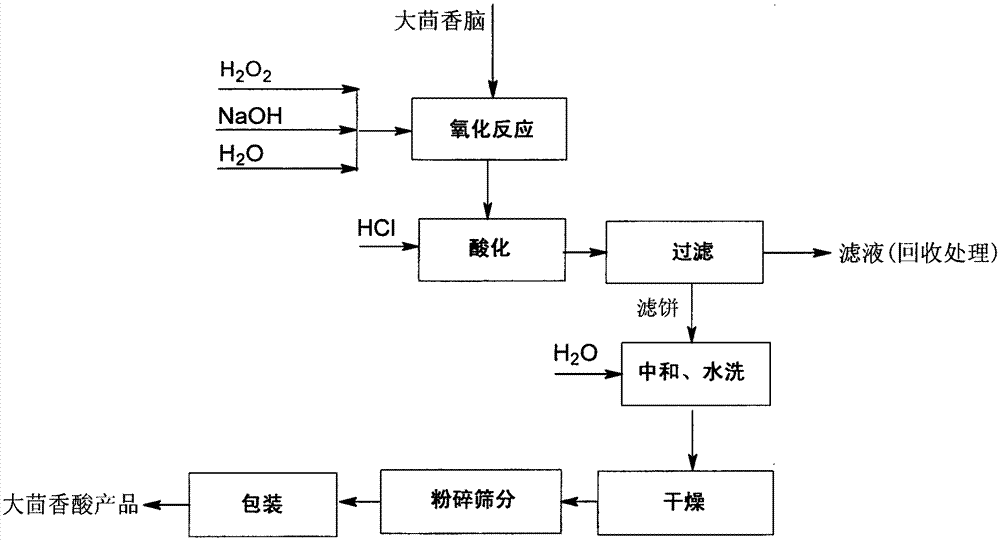

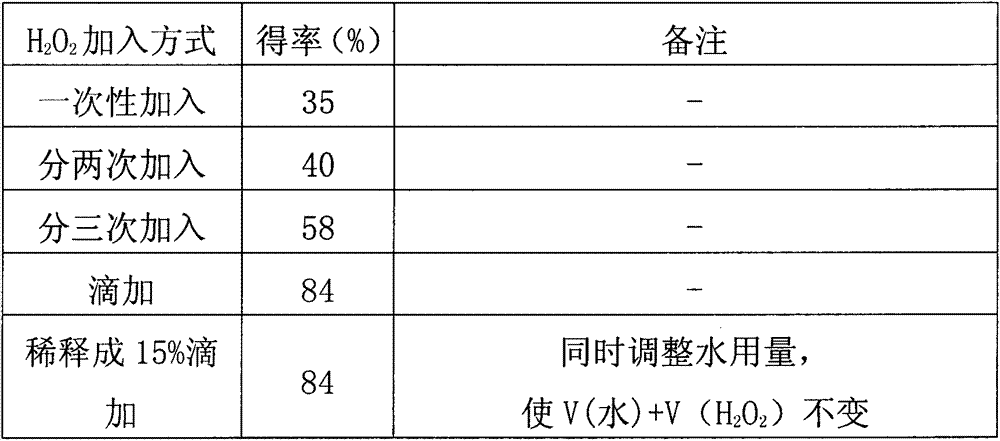

Method used

Image

Examples

Embodiment 1

[0064] Add 10g of anethole, 240ml of water, and 10g of NaOH into a 1000ml flask equipped with a reflux condenser, a thermometer, and a dropping funnel, heat it to 80°C in a stirring water bath, and then add dropwise a total of 295ml of anethole with a mass percentage concentration of 30% to the flask. h 2 o 2 , Control the rate of addition, 4h dropwise, and then stir the reaction for 5h, the reaction is terminated. After the reaction, cool to room temperature, add concentrated hydrochloric acid until the pH is 2, filter, wash the filter cake with water until neutral, and dry to constant weight at 105°C to obtain 8.13 g of anilic acid product, with a yield of 81.3%.

Embodiment 2

[0066] Add 10g of anethole, 180ml of water, and 6g of NaOH into a 1000ml flask equipped with a reflux condenser, a thermometer, and a dropping funnel, heat it to 80°C in a stirring water bath, and then add dropwise a total of 230ml of anethole with a mass percentage concentration of 30% to the flask. h 2 o 2 , Control the rate of addition, 4h dropwise, and then stir the reaction for 4h, the reaction is terminated. After the reaction, cool to normal temperature, add concentrated hydrochloric acid until the pH is 2, filter, wash the filter cake with water until neutral, and dry to constant weight at 105°C to obtain 6.20 g of anilic acid product, with a yield of 62.0%.

Embodiment 3

[0068] Add 10g of anethole, 60ml of water, and 4g of NaOH into a 500ml flask equipped with a reflux condenser, a thermometer, and a dropping funnel, heat it to 80°C in a stirring water bath, and then add dropwise a total of 150ml of anethole with a mass percentage concentration of 30% to the flask. h 2 o 2 , Control the rate of addition, 4h dropwise, and then stir the reaction for 3h, the reaction is terminated. After the reaction, cool to normal temperature, add concentrated hydrochloric acid until the pH is 2, filter, wash the filter cake with water until neutral, and dry to constant weight at 105°C to obtain 5.0 g of anilic acid product, with a yield of 50.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com