Extraction method of alpha-zein component

A technology of zein and extraction method, which is applied in the field of extraction of α-zein components, can solve the problems that it is difficult to effectively separate, α-zein is only microgram level and cannot meet industrial applications, and achieves high purity, The effect of high content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

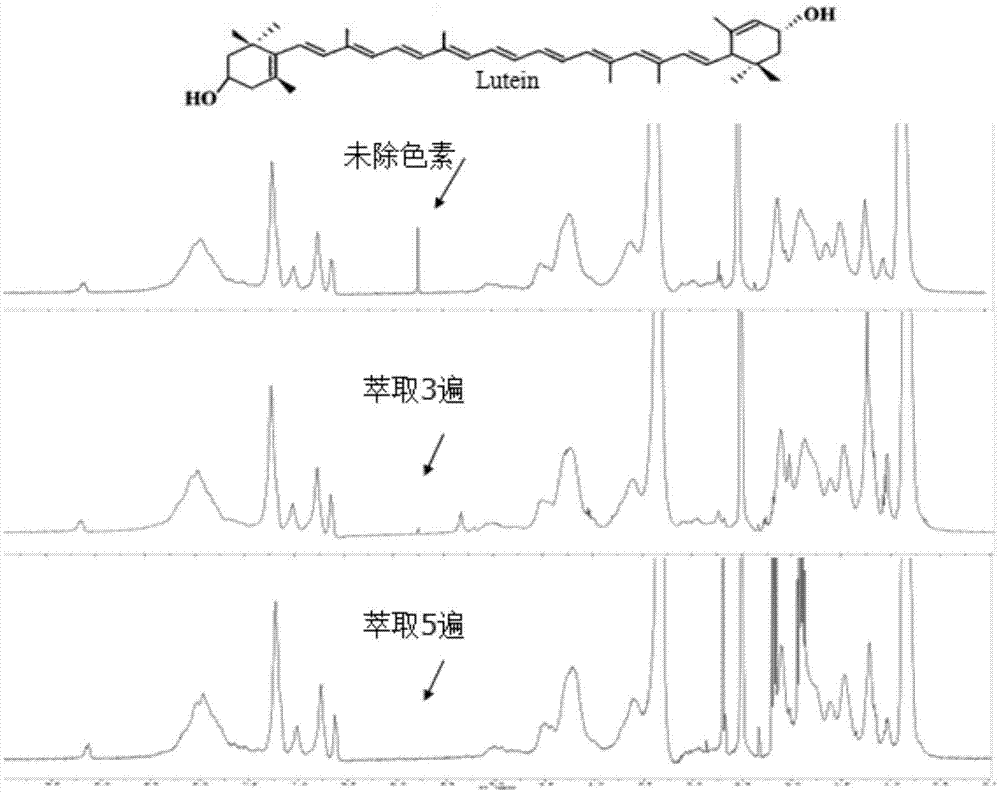

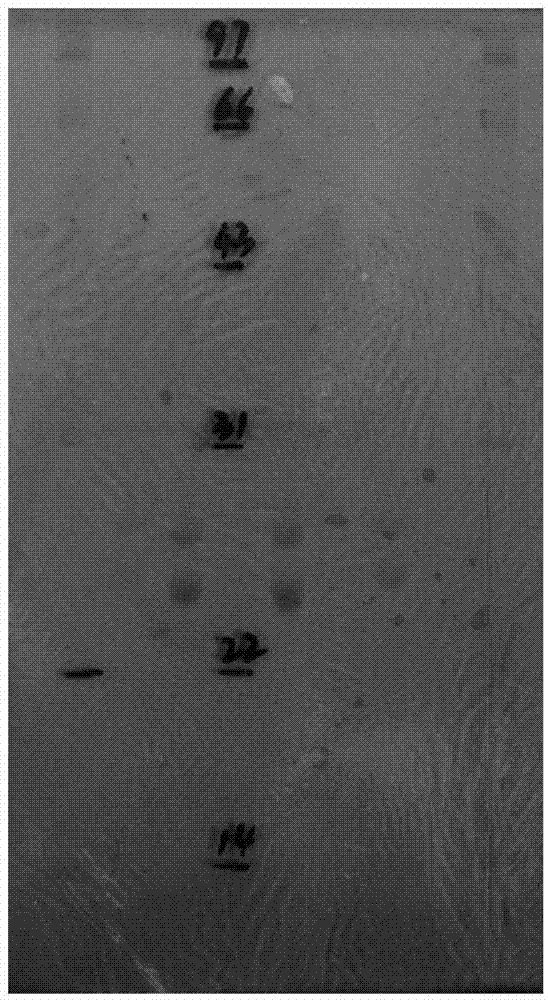

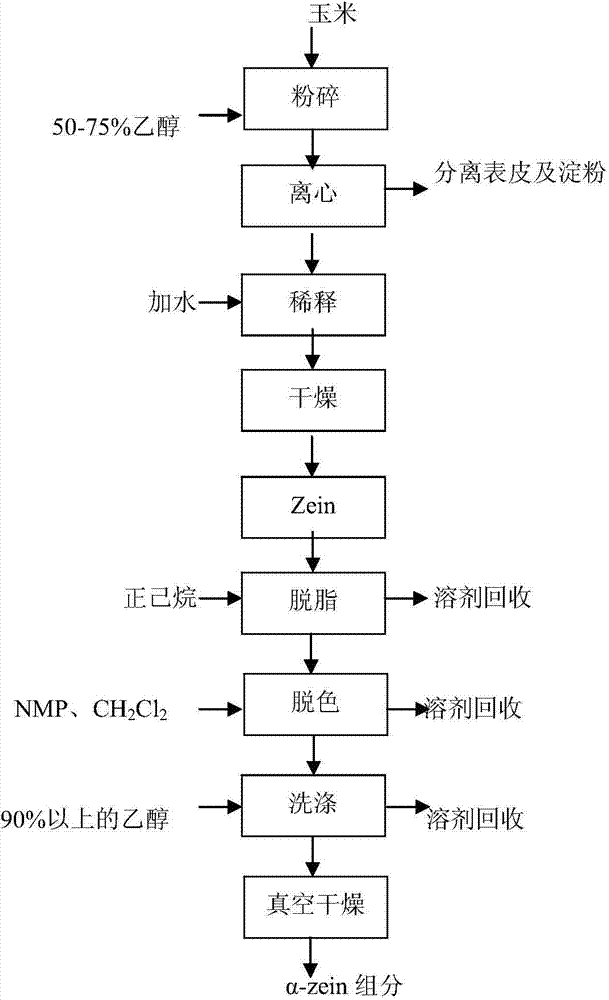

[0021] 1 part of corn flour was dissolved in 5 parts of 50-75% ethanol, and the supernatant was obtained by centrifugation. Add water to dilute until there is no protein precipitation, and then dry to obtain zein. Use solvents such as n-hexane to remove the grease in zein, take 1 part of defatted Zein and dissolve it in 30 parts of N-methylpyrrolidone, and extract repeatedly 3 times with 90 parts of dichloromethane to remove riboflavin. Finally, it was washed with more than 90% ethanol solution, centrifuged to take the supernatant, diluted with water to a concentration below 50%, and filtered; the filtered solid was washed with n-hexane, and vacuum-dried to obtain white α-zein powder. attached figure 1 for riboflavin 1 H NMR figure, this figure illustrates that after extraction 3 times, the residual amount of riboflavin in zein is only 6%. attached figure 2 This is the sodium dodecyl sulfate-acrylamide gel electrophoresis (SDS-PAGE) picture of the obtained white α-zein po...

Embodiment 2

[0023] 1 part of defatted Zein was dissolved in 30 parts of DMSO and washed 5 times in 90 parts of ether to remove riboflavin. Finally, it was washed with more than 90% methanol solution, centrifuged to take the supernatant, diluted with water to a concentration below 50%, and filtered; the filtered solid was washed with petroleum ether, and vacuum-dried to obtain white α-zein powder. attached figure 1 for riboflavin 1 HNMR figure, which shows that after 5 extractions, riboflavin in zein is not detected.

Embodiment 3

[0025] 1 part of defatted Zein was dissolved in 30 parts of NMP, and extracted twice in 90 parts of dichloromethane to remove riboflavin. Finally, it was washed with more than 90% isopropanol solution, centrifuged to take the supernatant, diluted with water to a concentration of less than 50%, and filtered; the filtered solid was washed with n-hexane, and vacuum-dried to obtain white α-zein powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com