Method for growing high-quality all-component adjustable ternary semiconductor alloy

A semiconductor, all-component technology, used in semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problem of low crystal quality, and achieve high electron mobility, strong band-edge luminescence, and low background electron concentration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] In this example, five pieces of high-quality In x Ga 1-x N alloy, In components are 0.1, 0.3, 0.5, 0.7, 0.9 respectively. The MBE method is used to grow on the GaN template. The growth process is carried out in an ultra-high vacuum growth chamber. The high-purity (7N) metal source is generated by a K-Cell source furnace. The nitrogen source is a radio frequency plasma nitrogen source. The growth process uses reflected high-energy electrons. In situ monitoring by diffractometer RHEED.

[0036] The preparation method of the full-component adjustable ternary semiconductor alloy in this embodiment includes the following steps:

[0037] 1) Pre-treat the template to make the surface of the template clean:

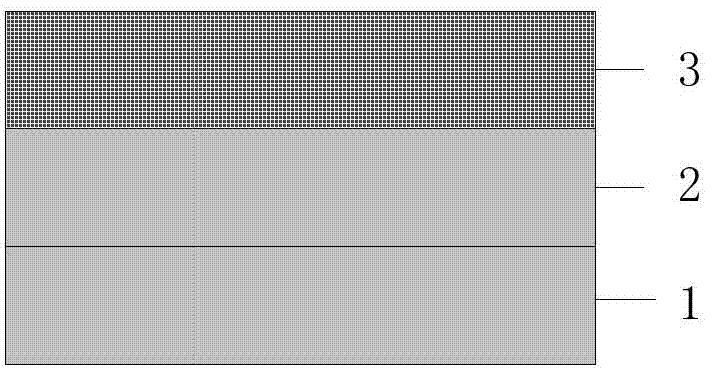

[0038] Raise the temperature of the GaN template 1 to about 600°C, bake for 10-30 minutes, then raise the temperature of the GaN template to about 800°C, and grow a layer of GaN material 2 with a thickness of 50-100nm, such as figure 1 shown;

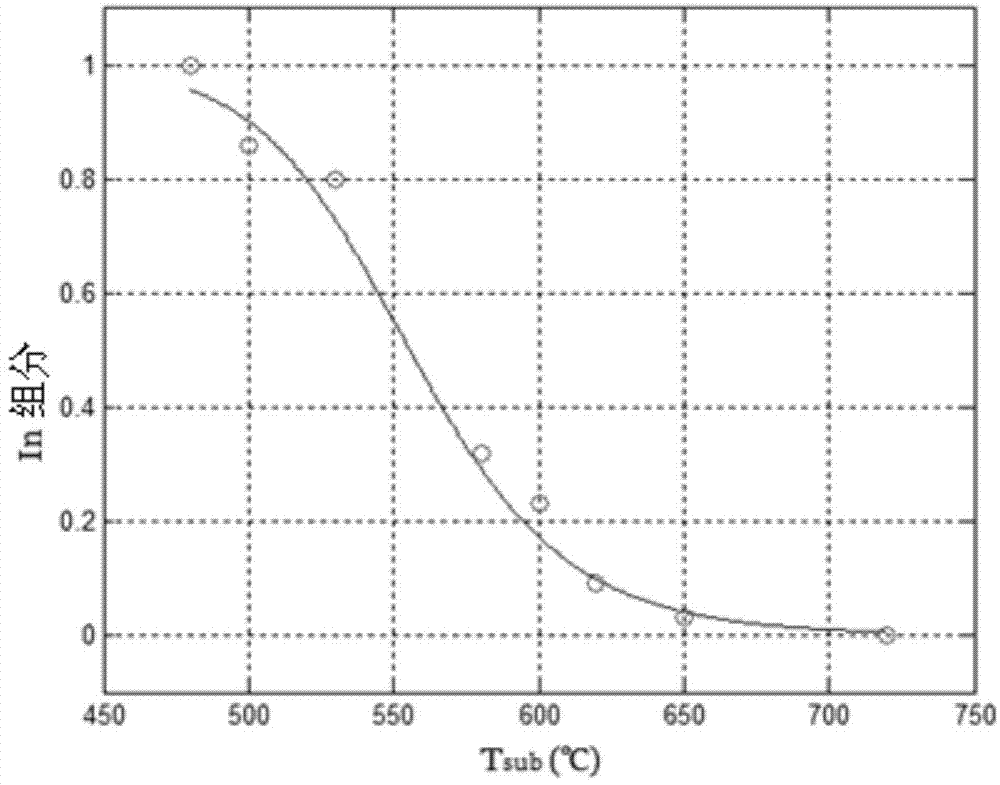

[0039] 2) Determine the...

Embodiment 2

[0051] In this embodiment, growth of In lattice-matched with GaN 0.18 Al 0.82 N alloy. The MBE method is used to grow on the GaN template. The growth process is carried out in an ultra-high vacuum growth chamber. The high-purity (7N) metal source is generated by a K-Cell source furnace. The nitrogen source uses a radio frequency plasma nitrogen source, and the growth process uses reflective high-energy electrons. In situ monitoring by diffractometer RHEED.

[0052] The preparation method of the full-component adjustable ternary semiconductor alloy in this embodiment includes the following steps:

[0053] 1) Pre-treat the template to make the surface of the template clean:

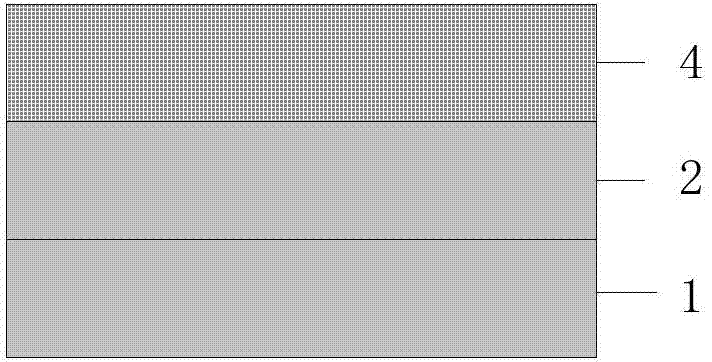

[0054] Raise the temperature of the GaN template 1 to about 600°C, bake for 10-30 minutes, then raise the temperature of the GaN template to about 800°C, and grow a layer of GaN material 2 with a thickness of 50-100nm, such as image 3 shown;

[0055] 2) Determine the composition In of each atom of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com