Organic electroluminescence device and manufacturing method thereof

An electroluminescence device and a luminescence technology are applied in the direction of organic semiconductor devices, electric solid devices, chemical instruments and methods, etc., and can solve the problems of not making the thickness too thin, reducing the probability of exciton recombination, and exciton loss. Achieve the effect of increasing the electron transmission rate, enhancing the electron transmission, and increasing the probability of recombination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The preparation method of the above-mentioned organic electroluminescent device comprises the following steps:

[0038] S1. First carry out photolithographic treatment on the anode base, cut it into the required size, and then clean it. The cleaning process is to use detergent, deionized water, acetone, ethanol, and isopropanol to ultrasonically for 15 minutes each to remove the surface of the anode base. Organic Pollutants;

[0039] S2. Perform oxygen plasma treatment on the conductive anode layer of the cleaned anode base to increase the work function of the conductive anode layer of the anode base; the treatment time is 5-15min, and the treatment power is 10-50W;

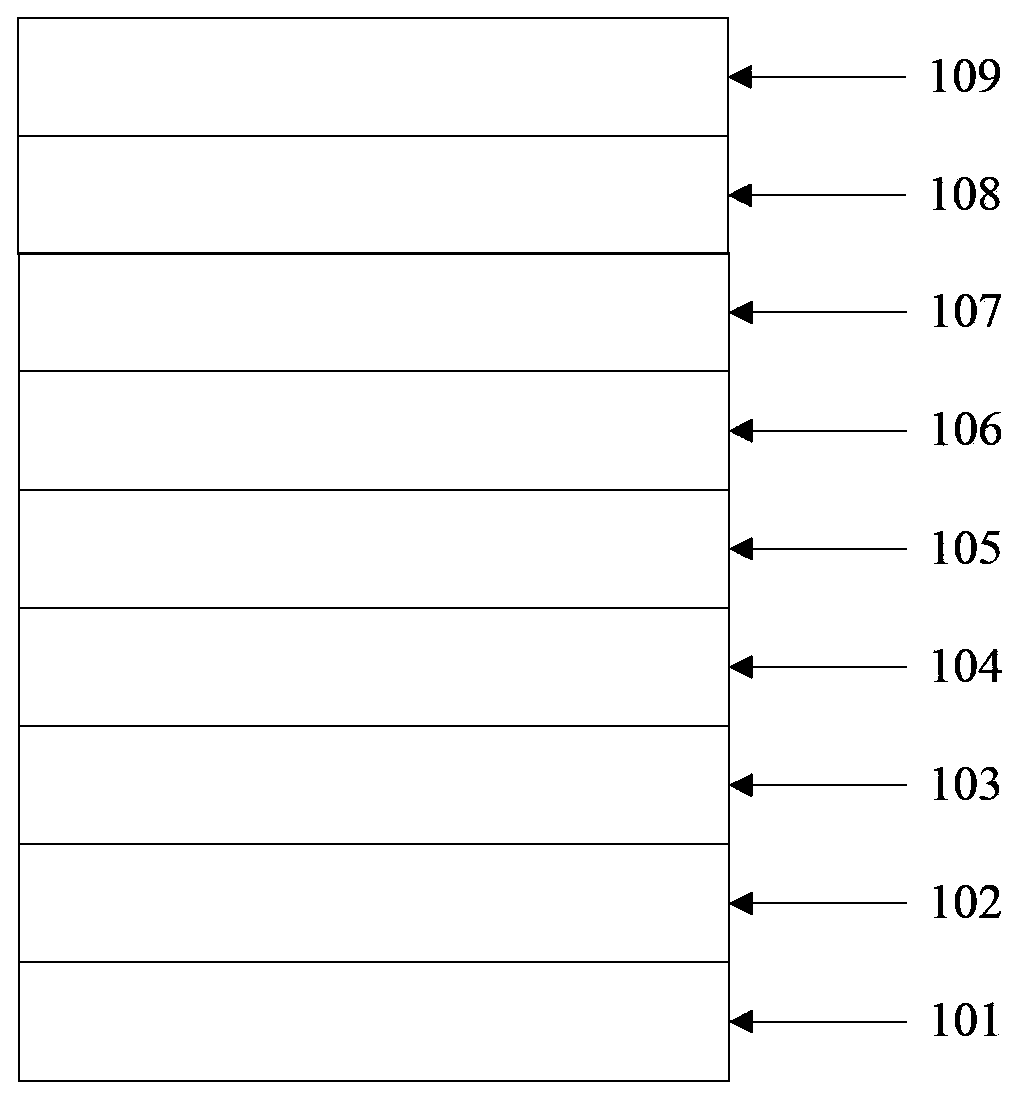

[0040] S3. In the vacuum coating equipment, sequentially vapor-deposit a hole injection layer, a hole transport layer, a light-emitting layer and a first electron transport layer on the conductive anode layer of the anode substrate;

[0041] S4. Then, electron beam evaporation is used to deposit a spacer ...

Embodiment 1

[0049] First, the ITO glass is washed with detergent, deionized water, and ultrasonic for 15 minutes to remove the organic pollutants on the surface of the ITO glass. After cleaning, the ITO layer of the ITO glass is treated with oxygen plasma. The treatment time is 5 minutes and the power is 50W;

[0050] Secondly, on the surface of the ITO layer after oxygen plasma treatment, the evaporated hole injection layer (the material is WO 3 , thickness is 40nm), hole transport layer (material is NPB, thickness is 40nm); light-emitting layer (material is Ir(ppy) 3 Doped into TCTA, expressed as TCTA:Ir(ppy) 3 , Ir(ppy) 3 The doping mass percentage is 10%; the thickness is 20nm), the first electron transport layer (the material is TAZ, the thickness is 60nm);

[0051] Then the electron beam evaporates the spacer layer: the material is ZnO, and the thickness is 40nm;

[0052] Then, on the surface of the spacer layer, the evaporation-assisted electron transport layer (made of ZnS with...

Embodiment 2

[0055] First, the ITO glass is washed with detergent, deionized water, and ultrasonic for 15 minutes to remove the organic pollutants on the surface of the ITO glass. After cleaning, the ITO layer of the ITO glass is treated with oxygen plasma. The treatment time is 15 minutes and the power is 10W;

[0056] Subsequently, on the surface of the ITO layer after oxygen plasma treatment, the evaporated hole injection layer (the material is MoO 3 , thickness is 20nm), hole transport layer (material is TAPC, thickness is 60nm), light-emitting layer (material is Ir(MDQ) 2 (acac) doped into NPB, expressed as NPB:Ir(MDQ) 2 (acac), Ir(MDQ) 2 (acac) doping mass percentage is 2%; thickness is 20nm), the first electron transport layer (material is TPBi, thickness is 40nm)

[0057] Then the electron beam evaporates the spacer layer, the material is MgO, and the thickness is 20nm;

[0058] Then, on the surface of the spacer layer, the vapor-deposited auxiliary electron transport layer (mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com