Solvent extraction method for active polysaccharide of wheat bran

A technology of wheat bran and active polysaccharides, applied in organic active ingredients, pharmaceutical formulas, allergic diseases, etc., can solve problems such as environmental pollution, lack of economic feasibility of recycling, etc., achieve rich sources, significant immune regulation function, and industrialization The effect of developing a bright future

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1, the solvent method extraction of wheat bran active polysaccharide

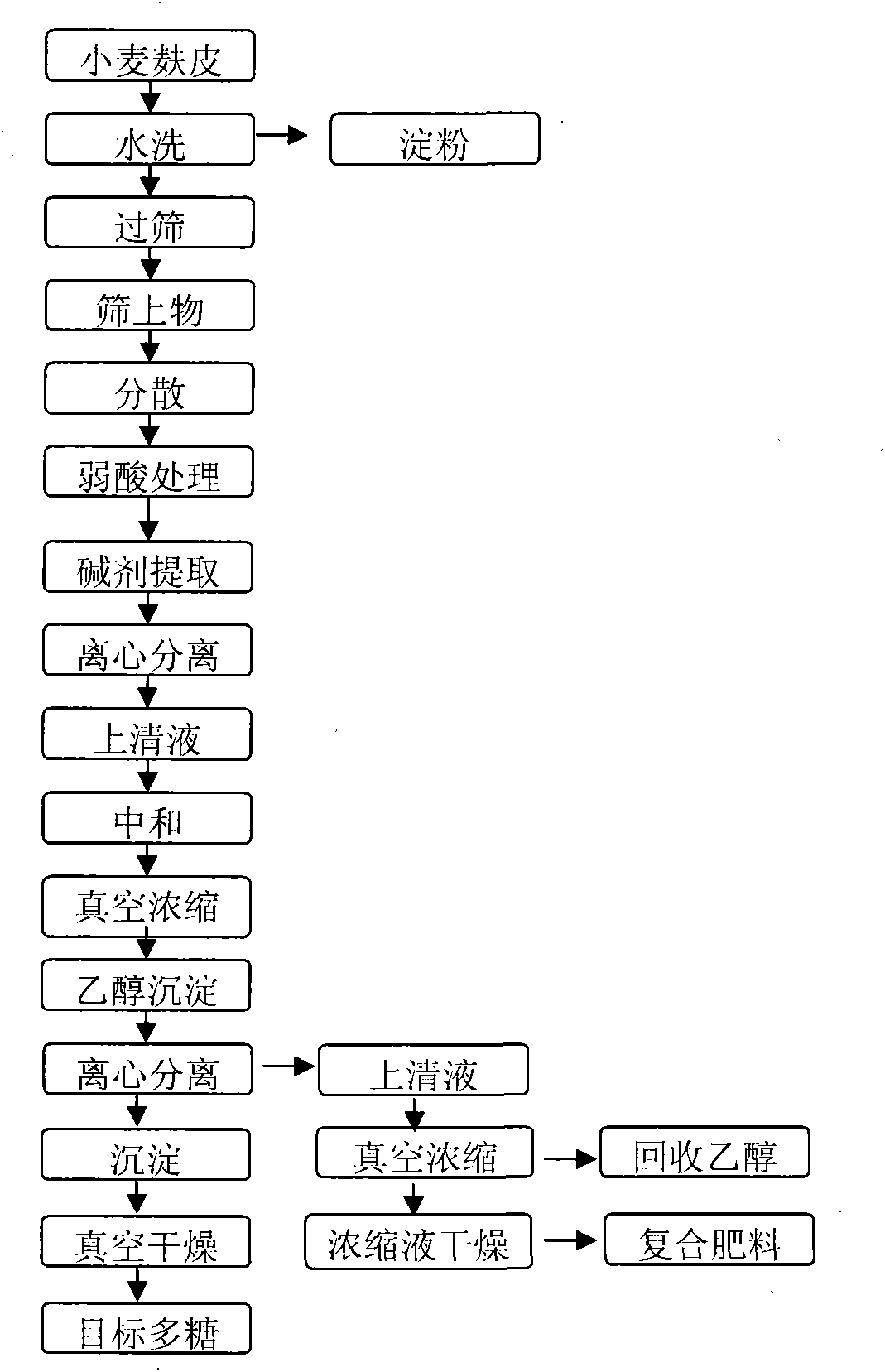

[0035] 1. Polysaccharide extraction: the flow chart of polysaccharide extraction is as follows figure 1 shown.

[0036] 1) Pretreatment of wheat bran

[0037] Weigh 100 g of wheat bran, disperse it in 500 mL of water, stir at room temperature for 30 minutes, pass through a 60-mesh sieve, and collect the sieved material; repeat this process 3-5 times until the water is clear, and the wheat bran with deendosperm starch is obtained.

[0038] 2) Acid hydrolysis

[0039] The starch-removed wheat bran was dispersed into 800 mL of citric acid solution with a concentration of 0.15 M, placed in a 50.0° C. insulation tank and stirred for 3.0 h to obtain a mixed solution of acid-hydrolyzed wheat bran.

[0040] 3) Alkaline extraction

[0041] Add KOH to the acid-hydrolyzed wheat bran mixed solution to adjust the concentration of the alkali solution to 0.08M; place it at 40.0°C and stir for extract...

Embodiment 2

[0075] Embodiment 2, the solvent method extraction of wheat bran active polysaccharide

[0076] 1. Polysaccharide extraction: the flow chart of polysaccharide extraction is as follows figure 1 shown.

[0077] 1) Pretreatment of wheat bran

[0078] Weigh 1000g of wheat bran, disperse it in 6L of water, stir at room temperature for 30min, pass through a 60-mesh sieve, and collect the sieve; repeat this process 4 times until the water is clear, and the wheat bran with degerminated starch is obtained.

[0079] 2) Acid hydrolysis

[0080] Disperse the destarched wheat bran into 10L of citric acid solution with a concentration of 0.05M, place it in an insulated tank at 80.0°C and stir for 1.0h to obtain a mixed solution of acid-hydrolyzed wheat bran.

[0081] 3) Alkaline extraction

[0082] Add KOH to the acid-hydrolyzed wheat bran mixed solution to adjust the concentration of the alkali solution to 0.05M; place it at 50.0°C and stir for extraction, and the extraction time is 0....

Embodiment 3

[0102] Embodiment 3, the solvent method extraction of wheat bran active polysaccharide

[0103] 1. Polysaccharide extraction: the flow chart of polysaccharide extraction is as follows figure 1 shown.

[0104] 1) Pretreatment of wheat bran

[0105] Weigh 10 kg of wheat bran, disperse it in 4.5 L of water, stir at room temperature for 30 minutes, pass through a 60-mesh sieve, and collect the sieve; repeat this process 5 times until the water is clear, and the wheat bran with degerminated starch is obtained.

[0106] 2) Acid hydrolysis

[0107] Disperse the destarched wheat bran into 120 L of citric acid solution with a concentration of 0.10 M, place it in a heat preservation tank at 60.0° C. and stir for 2.4 hours to obtain a mixed solution of acid-hydrolyzed wheat bran.

[0108] 3) Alkaline extraction

[0109] Add KOH to the acid-hydrolyzed wheat bran mixed solution to adjust the concentration of the alkali solution to 0.01M; put it at 60.0°C and stir for extraction, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com