Method for extracting and preparing peat fulvic acid and drug application

An extraction method, a technology of fulvic acid, which is applied in drug combinations, antipyretics, antineoplastic drugs, etc., can solve the problems of easy pollution of resin, large loss of alcohol solvent volatilization, difficult industrial production, etc., and achieve the effect of avoiding high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A method for extracting and preparing peat yellow humic acid;

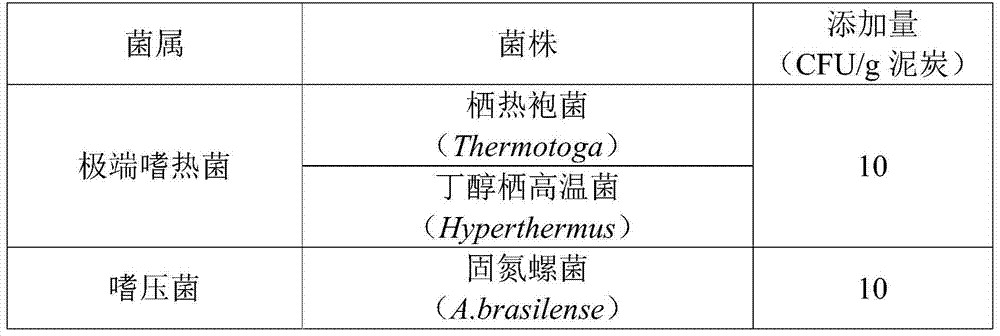

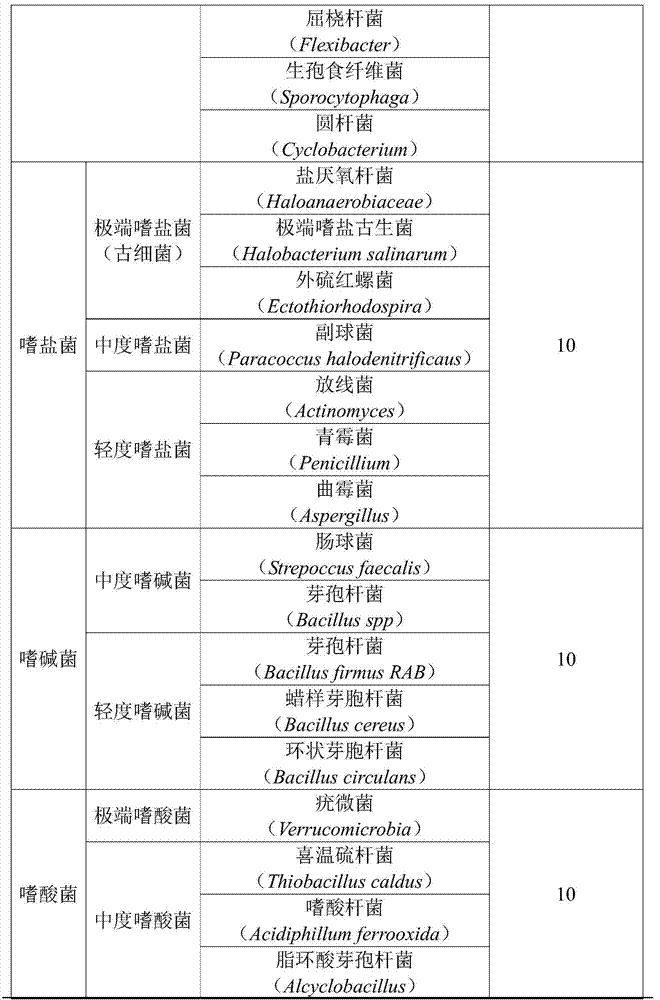

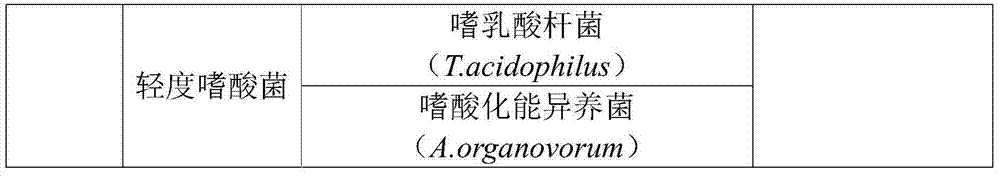

[0052] The peat in this embodiment is Yunnan Shiping peat; the mass ratio of peat and water in the aqueous solution of peat is 1:5; the strains used are shown in the following table:

[0053]

[0054]

[0055]

[0056] Described extraction method comprises the following steps:

[0057] (1) Put each strain in the culture medium and cultivate it to the logarithmic growth phase; the medium includes: 10g of fulvic acid, 10g of agar powder, 5g of peptone, and 1000mL of deionized water; at 38°C and a pressure of 0.1MPa, Shake and domesticate at a shaking speed of 300rpm. After culturing to the logarithmic phase, perform 10-fold volume expansion according to three levels of I, II, and III. The medium for expansion includes: 10g of fulvic acid, 5g of agar powder, and peptone 5g, 1000mL deionized water;

[0058] (2) Flow extreme thermophiles, barophiles, halophiles, alkalophiles and acidophiles (Genencor ...

Embodiment 2

[0061] A method for extracting and preparing peat yellow humic acid;

[0062] The peat in the present embodiment is Zoige peat in Sichuan; the mass ratio of peat and water in the aqueous solution of peat is 1:10; the strains used are as shown in the table below:

[0063]

[0064]

[0065]

[0066] Described extraction method comprises the following steps:

[0067] (1) Put each strain in culture medium and cultivate it to the logarithmic growth phase; wherein, the culture medium includes: 10g of fulvic acid, 10g of agar powder, 5g of peptone, 1000mL of deionized water; Under the condition of 0.1MPa, shake and acclimatize at a shaking speed of 300rpm. After culturing to the logarithmic phase, in the seed tank, carry out 10-fold volume expansion according to three levels of I, II, and III. The medium for expansion includes: Fulvic acid 10g, agar powder 10g, peptone 5g, deionized water 1000mL;

[0068] (2) Flow extreme thermophilic bacteria, barophilic bacteria, halophi...

Embodiment 3

[0071] A method for extracting and preparing peat yellow humic acid;

[0072] The peat in the present embodiment is Heilongjiang birch forest peat, and the mass ratio of peat and water in the aqueous solution of peat is 1:2; The strains used are shown in the following table:

[0073]

[0074]

[0075] Described extraction method comprises the following steps:

[0076] (1) Put each strain in the culture medium and cultivate it to the logarithmic growth phase; wherein, the medium includes: 10g of fulvic acid, 1-10g of agar powder, 5g of peptone, 1000mL of deionized water; at 35°C Under the conditions of 38°C and a pressure of 0.1MPa, shake and acclimatize at a shaking speed of 300rpm. After culturing to the logarithmic phase, perform 10-fold volume expansion in the seed tank according to three levels of I, II, and III;

[0077] (2) Flow extreme thermophilic bacteria, barophilic bacteria, halophilic bacteria, alkalophilic bacteria and acidophilic bacteria into the peat aqu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com